TOKYO, March 19, 2015- Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it has developed a distributed feed-back (DFB) laser diode for 25Gbps optical-fiber communication in 100Gbps systems operating in a wide range of temperatures from -20 to 85 degree Celsius. Four DFB laser diodes can be mounted on 100Gbps high-speed communication transceivers for optical fiber communication to achieve lower power consumption and enhanced communication performance for increased efficiency in data centers. The new DFB laser diode will also help to simplify the requirements for transceiver design.

Features

1) High output power even at high temperatures, low power consumption and high performance

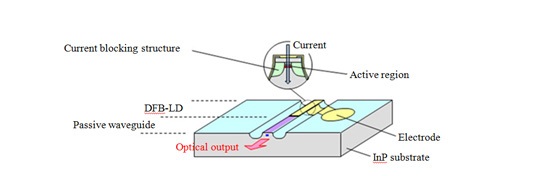

- New current-blocking structure achieves low capacitance for efficient current injection without degrading high-speed response.

- Current injection efficiency in active region improved 12% compared with company's existing products. More than 10mW output power at 85oC is obtained.

- High-temperature operability eliminates the need for cooling, helping to reduce power consumption.

- Transmitter Optical Sub Assembly (TOSA) for 100Gbps transmission includes 4-wavelength 25Gbps DFB lasers. The DFB lasers' high output power compensates for the optical loss caused by an optical multiplexer inside the TOSA.

2) Wide-ranging temperature operability and high-quality modulation waveform help to simplify the designs of 100Gbps transmission systems

- Current-blocking structure with low capacitance and short laser length (75% the length of the company's existing products) enables top-quality modulation waveform with mask margin of more than 20%

- High-quality modulation waveform simplifies laser-driving circuit design and therefore communication transceiver design.

In the effort to develop a DFB laser with high-speed response suited to 25Gbps operation, a current-blocking structure with semi-insulating semiconductors that have high electrical resistance by doping impurity showed promise, but high output power was not possible because of poor current injection efficiency in the active region. In response, Mitsubishi Electric developed the new current-blocking structure with semi-insulating semiconductors that realize efficient current injection in the active region.