Woburn, MA, January 7, 2016—Innovations in Optics, Inc. launches it next generation LumiBright™ 3300B UV-LED Illuminators for Digital Light Processing (DLP) applications such as 3D printing, maskless lithography, prepress digital imaging, phototherapy, and refractive surgery. DLP and the DLP® logo are trademarks of Texas Instruments. The UV-LED technology offers more reliable and economical advantages over lasers and arc lamps in UV DLP systems. High optical power over 20W matches the power output of fiber-coupled laser diode bundles at lower cost.

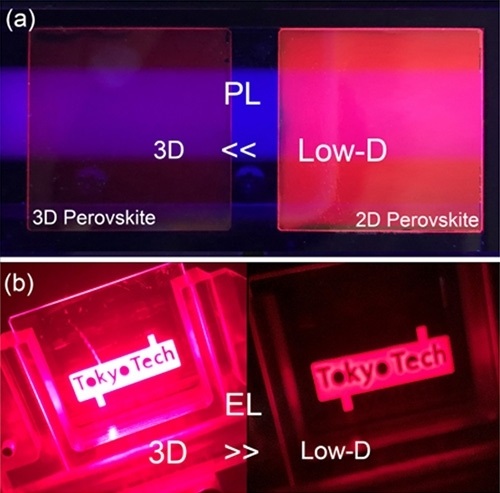

The Model 3300B series of UV-LED Illuminators for DLP comprise a densely packed UV-LED array. Standard LED center wavelengths include 365 nm, 375 nm, 385 nm, 395 nm and 405 nm. Single or multi-wavelength configurations are available. The combination of different wavelengths optimizes the spectral balance of the exposure for all types of UV processed materials.

The multi-wavelength feature, in maskless lithography for manufacturing printed circuit boards, supports many photoresists ranging from general purpose dry film to conventional solder mask. For pre-press operations in the printing industry, computer-to-plate (CtP) systems with UV-LED can support highly cost-efficient, mature UV-plate technology. In computer-to-screen (CtS) printing, UV LED and DLP exposure eliminates the need for several consumables and production steps improving process efficiency at lower cost with higher quality.

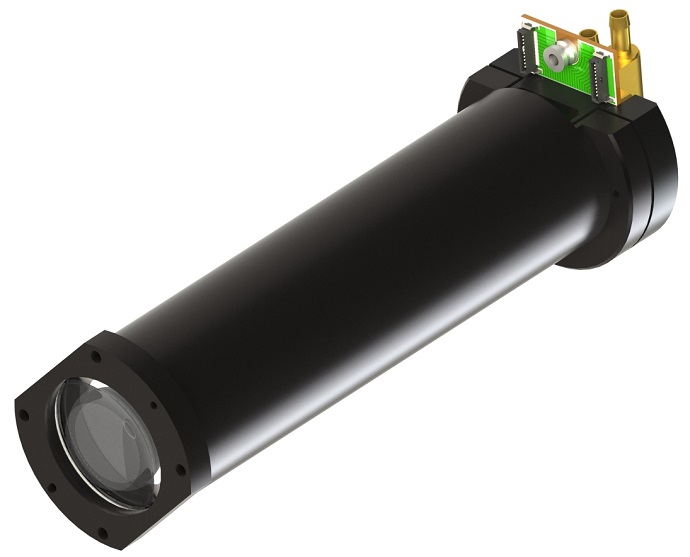

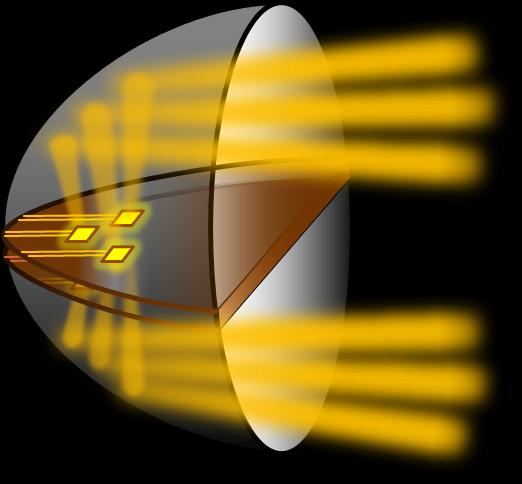

The 3300B series features a UV-LED array coupled to a high efficiency, non-imaging collection optic with an aspect ratio matched to DLP chips. An integral imaging optic is telecentric over the entire DLP and is constrained in angle to match the micromirror tilt angle. Water-cooling allows the UV-LED array to be operated at a very high current density. The result is an extremely high power, highly uniform UV-LED illuminator which provides unprecedented speed and resolution for UV DLP applications.

Up to an 18-die UV-LED array can be integrated into the 3300B series which can be driven and modulated independently for precise exposure control in direct imaging systems. Innovations in Optics has also developed an OEM driver with Ethernet and serial control to support this feature. The driver provides independent current control to each of the LED die to achieve optimal performance and lifetime. Thermal management in the 3300B series includes a water heat exchanger for cooling of the LED array, and an onboard thermistor for temperature monitoring. In addition to multi-wavelength, other user options include a selection of non-imaging collection optics to match various DMD sizes, up to two photodetectors with optional integral spectral bandpass filters for feedback control or exposure monitoring, fixed or adjustable mounting flanges, and straight or right-angle hose barbs for the water heat exchanger.

Innovations in Optics, Inc. (IOI), founded in 1993 and located near Boston, is widely recognized as a leading innovator in the areas of high brightness LED chip-on-board (COB) products and illumination engineering and technology. Leveraging a unique, multidisciplinary approach to systems design, the company pushes the technology envelope to develop industry-leading ultra-high brightness LED products. IOI light engines and illumination systems feature patented and patent-pending optics which collect, direct and maximize output efficiency and uniformity, enabling some of today’s most revolutionary solutions in cutting-edge technical applications for LED light sources.