July 22, 2013

We are just starting to develop smart textiles. So far the problem has always been that it was not possible to apply the electronic components, called organic semiconductors, to three-dimensional structures such as fibres in a reproducible way. But now Darmstadt’s material scientists have developed a machine with which electronically active materials can be vacuum deposited onto threads.

“In theory, reproducible rotational coating with semiconductor components opens up a whole new world of possibilities in smart textiles,” reports Prof. Heinz von Seggern, director of the field of Electronic Material Properties at the TU Darmstadt. In other words, from the engineering point of view, this is an important step forward weaving electronic components into clothing.

Working towards smart textiles

The materials scientist Tobias Könyves-Toth, who had the idea for the machine as part of the LUMOLED joint project of the Federal Ministry for Education and Research (BMBF), has been able to vacuum deposit organic semiconductor elements onto glass fibres.

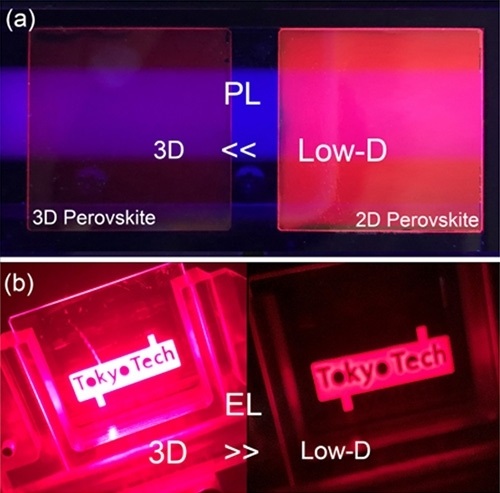

“We turned to organic light emitting diodes known as OLEDs because they require the highest standards concerning the substrates. Today, we are able to apply functioning OLEDs to a thread and make it glow. Applying other devices such as transistors or solar cellsphotovoltaics includes other problems, but is comparatively less complex when it comes to the actual coating.”

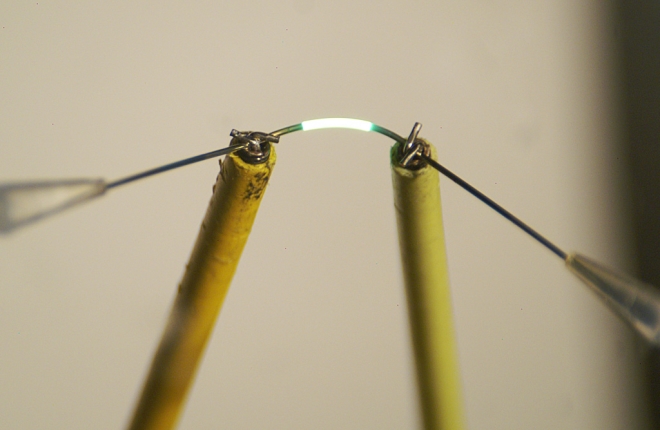

One problem in small molecule fibre coating is that it has to be carried out under vacuum conditions. “With our rotational coating process we have found a possibility to evenly coat the fibre and then being able to remove it from the vacuum without it coming into contact with air, because OLEDs are highly sensitive to oxygen and water,” explains Tobias Könyves-Toth.

The components are applied to the thread by heating the materials in the vacuum until they sublime or evaporate. The materials condensate on the fibre in exactly the same way as water does when it is heated on a cooker, rises as steam and condenses on a window. A total of seven layers have to be applied to the fibre, some of them just a few atoms thick. “The layers that are applied to the fibres are only about 200 nanometres thick; in other words, fine dust particles are 50 times bigger than the layer thickness of the OLEDs.” And this is where another problem arises: textile fibres have a rough surface. However, the electronic components only work on a smooth surface; even scratches of just a few nanometres’ thickness can cause problems such as short circuiting.

Still lacking durability

“That is why we tried to use glass fibres for our first trials,” Tobias Könyves-Toth continues, “because they have a very smooth surface.” But glass fibres are also brittle, and are not suitable for weaving textiles. Therefore the people at the TU are now carrying out trials with polymer-coated glass fibres. The aim is to utilize the polymer fibre coating to smoothen the fibre surface for a successful subsequent coating with organic semiconductor elements and finally provide flexibility to be woven in the textile.

Tobias Könyves-Toth started with a fibre of 1 mm thickness and things have moved on quite satisfactorily. “Today we have even been able to get a 500 micrometre fibre to glow at 5 millimetres,” he is delighted to report. “And even if the fibre has been bent, the OLEDs still work.”

However, although the trials have been a great success, there is still some way to go before smart textiles are reality. The lifetime of the electric functionality is limited. There is as yet no solution for a protective layer to protect the organic semiconductor molecules against oxygen and moisture.

The glowing fibres are yet to be able to cope with the mechanical loads that occur during the weaving process and when the garments are worn. Picture: Katrin Binner

Although first attempts have been made, it is going to take some time before the process is ready for the market. And the fibres that have been used so far are still too brittle and too thick to be woven into textiles. Nor are the glowing fibres able to cope with the mechanical loads that occur during the weaving process and when the garments are worn.

The scientists at Darmstadt are now looking into patent registration. The textiles industry has shown much interest in their development, as

Professor von Seggern and Tobias Könyves-Toth found in Greece at the beginning of July, when they presented their process at the International Symposium on Flexible Organic Solutions (ISFOE 13).

There may still be much to do, but the first steps have been taken towards the reproducible and controllable production of smart textiles – and there is almost no limit to the possible applications. “The only limit that does exist is our own imagination,” Tobias Könyves-Toth sums up.