Neuchatel, 8 May, 2013 - CSEM has joined a recently launched €11.2 million European initiative that aims to help bring flexible OLEDs to market. The project - Flex-o-Fab - will create a pilotscale manufacturing line for flexible OLEDs and use it to develop reliable production processes. Funded through the EU's 7th Framework Programme, the Flex-o-Fab will strengthen Europe's leading position in the lighting industry by making flexible OLEDs a commercial reality.

Organic light-emitting diodes (OLEDs) are a revolutionary new light source. Emitting light efficiently over a large area, they open up a world of new lighting possibilities. The first OLED products - rigid glass tiles - are already on the market. However, OLEDs also offer the exciting possibility of being produced on plastic films to create flexible light sources. Flexible OLEDs could be produced at lower cost than glass-based OLEDs. Moreover, they could be embedded into most kinds of everyday objects.

While flexible OLEDs have been successfully demonstrated on the laboratory scale by many groups (CSEM among them), Flex-o-Fab aims to take them from lab to fab by developing reliable processes for manufacturing OLEDs on plastic foils. To achieve this, the project will set up a modular, integrated pilot production line and associated manufacturing chain. Flex-o-Fab will migrate existing sheet-to-sheet processes to roll-to-roll (R2R) production for a further reduction of costs and to enable high-volume production. The project will focus on lighting applications and aims to have a proof-of-concept pilot line operational by September 2015.

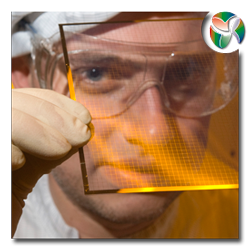

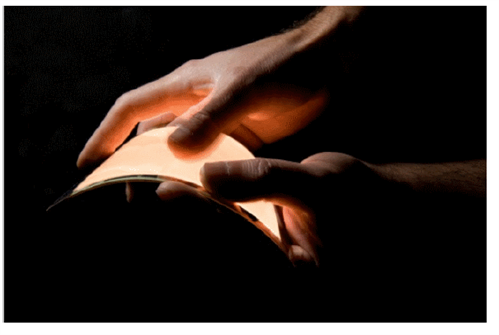

The Flex-o-Fab project aims to take flexible OLEDs (as seen in photo) from the lab to the fab. The project will demonstrate a reliable manufacturing process for OLED lighting foils, enabling market introduction within 3 years of the end of the project

Copyright © Holst Centre 2013

In collaboration with a range of partners, CSEM will contribute to develop new bonding-debonding solutions to facilitate reliable manufacturing of flexible OLEDs based on -foil on carrier- concept. The solutions developed will be compatible with the complete OLED processing flow. This will eventually provide the consortium with a reliable and R2R-compatible handling method for OLED processing on polymer foils.