12.03.2025

Be it sensors, cameras, or displays: Metasurfaces have the potential to fundamentally improve optical systems in our everyday lives. By controlling light more precisely, they drive compact, multi-functional solutions. At Hannover Messe, which starts on Monday, March 31, 2025, researchers from KIT (Karlsruhe Institute of Technology) will present an optical component that enables highly efficient light control at steep angles of incidence, overcoming previous limitations.

Conventional curved lenses, which direct light by refraction in glass or plastic, are often bulky and heavy, offering only limited control of light waves. Metasurfaces, in contrast, are flat and consist of an array of tiny structures known as meta-atoms. Meta-atoms influence light at a subwavelength scale and thus allow for highly precise control of the phase, amplitude, and polarization of light. “Using metasurfaces, we can influence the temporal shift, intensity, and direction of oscillation of light waves in a targeted way,” says Dr. Maryna Leonidivna Meretska, Group Leader at KIT’s Institute of Nanotechnology. “Thanks to its multiplex control capabilities, i.e. the simultaneous and targeted influencing of various parameters, a single metasurface can replace multiple optical components. Thus, the size of the optical system can be reduced without affecting its performance.” Production will also be simpler, “Metasurfaces can be manufactured using advanced lithography and etching technologies from the semiconductor industry, making scalable production is possible,” says Meretska.

Meta-grating with a Fourfold Increase in Efficiency

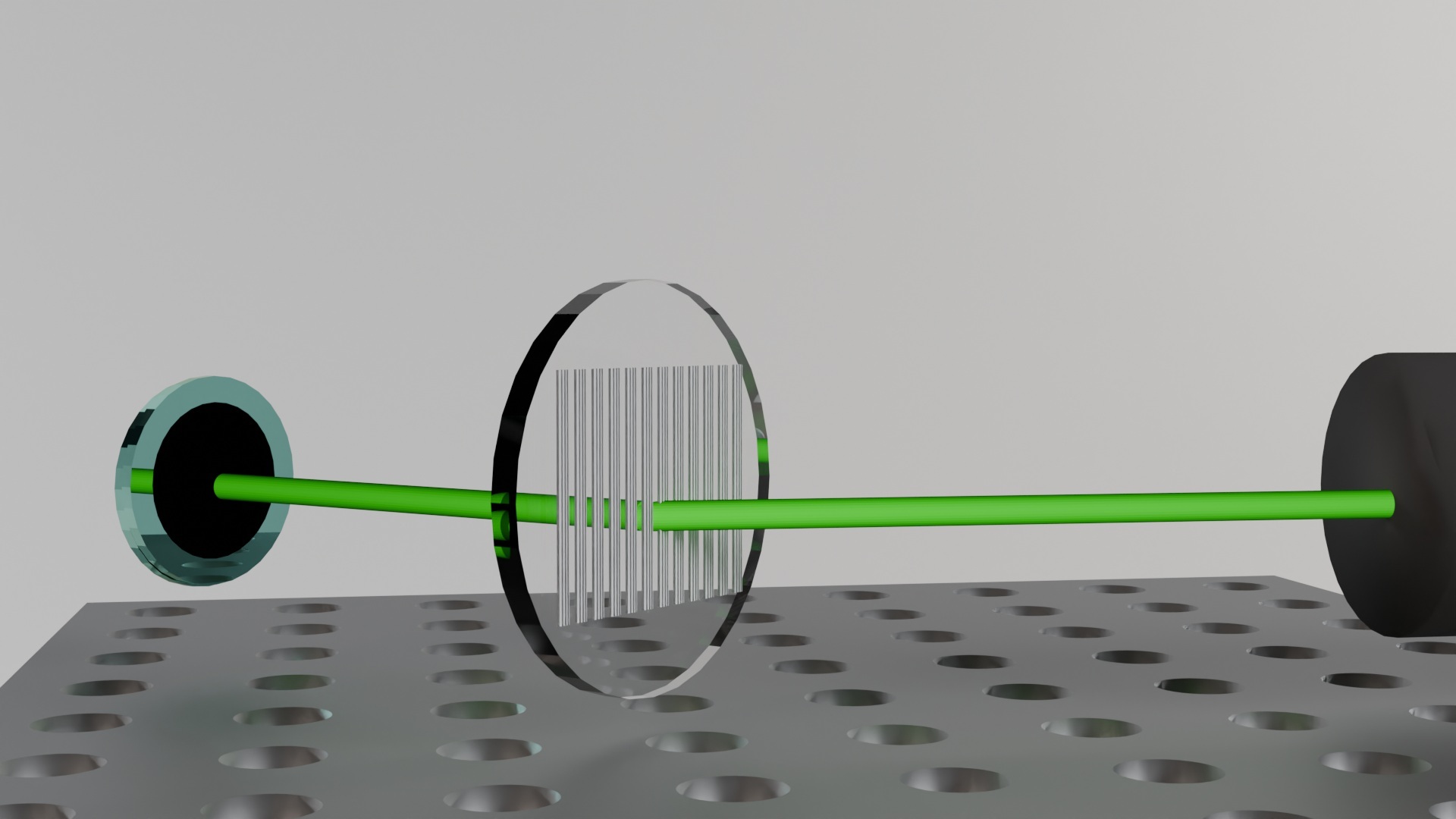

At Hannover Messe, Meretska and her team will present an optical diffraction meta-grating that was made using special KIT manufacturing equipment. Diffraction gratings are essential optical components that can be used in various industrial applications, such as spectroscopy, telecommunications, and laser systems. Usually, the efficiency of diffraction gratings decreases sharply as the angle of incidence of the light increases. The meta-grating developed at KIT is four times more efficient than conventional systems. “Our meta-grating offers unprecedented control of light under challenging conditions. This represents a significant advance for future applications requiring precise light control,” says Meretska. As the functionality has been proven with the prototype, the research group is currently developing targeted optical solutions for various industrial applications.

A Wide Range of Applications

The flat structure of meta-optical components makes them particularly suitable for cameras, sensors, and augmented-reality displays, as they offer improved functionality while reducing the size of optical systems. Other potential applications include materials sorting and quality control, medical imaging, microscopy, and solar cells. In addition, robotics and autonomous driving, both relying on object recognition, might benefit considerably from the technological advances of meta-optics.