June 23, 2017

Lenses with aspherical surfaces are frequently used these days, particularly in small and light high per-formance optics, in order to reduce spherical aberra-tion. However, conventional testing systems can only ensure the precision of the asphere manufacturing up to a certain degree. While the decentration of an as-pherical surface can be determined with the centra-tion measurement that is also used for spherical lenses, determining a possible tilt requires an addi-tional, off-axial test. Both measurement parameters are covered by the new AspheroCheck UP meas-urement system, which TRIOPTICS GmbH is pre-senting for the first time at Laser 2017 in Munich.

In order to ensure the best possible measurement precision, a completely automated measurement pro-cess that requires no manual interaction was imple-mented in the AspheroCheck UP. It starts with meas-urement of the surface decentration. This is based on the established measurement process of the Opti-Centric® systems, which precisely measures the cen-ters of curvature of both lens surfaces. This forms the basis for the subsequent alignment of the lens, in which the paraxial optical axis is brought into alignment with the rotation axis of the system by a motorized tilt and shift table. Finally, the surface tilt is measured by a non-contact sensor.

The positioning of the sensor plays an important role in achieving optimal measurement results with respect to tilt. The system calculates this from the previously entered lens data and automati-cally guides the sensor to the right angle, at the right height and the right distance from the sample.

"The complete automation of the entire process provides numerous advantages," explains product engineer Felix Hahne. "The most important aspect is that the entire process is carried out in a sin-gle pass, and is not interrupted in between the individual steps. This allows the measurement time to be shortened to less than a minute, making it faster than any other asphere measurement." In addition, the influencing factors that occur in the case of manual adjustment by the user are also reduced. "This significantly increases measurement accuracy," Hahne concludes.

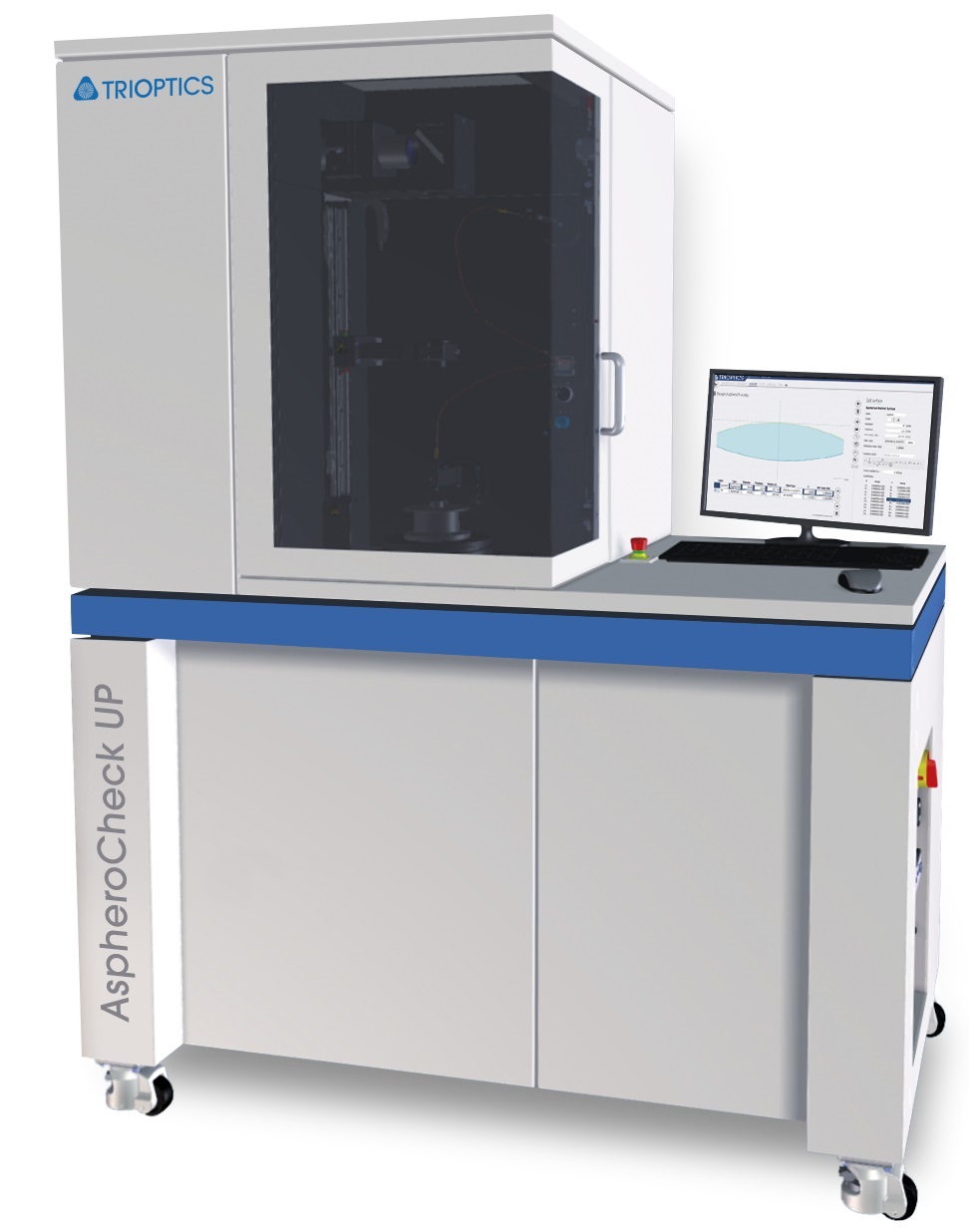

The fast, precise and operator-independent quality control possible with AspheroCheck UP makes the system particularly well suited for use in production facilities. This is also thanks to the compact structure of the device, which combines the measurement technology, a full-fledged PC workstation and storage for accessories.