12 December 2017

At the world’s leading trade fair for the photonics industry, Jenoptik will be presenting its solutions for the global megatrends digital world, healthcare and industry 4.0. Visit us from January 30 to February 1st at SPIE Photonics West 2018 at the Moscone Center, South Hall, booth #1023.

Jenoptik will also be exhibiting at SPIE BiOS 2018 on January 27-28 in the Moscone Center, West Hall, booth #8513.

New F-Theta objective lenses and beam expander

Four new completely fused silica F-Theta objective lenses, a fused silica beam expander for high-power laser applications, and three new standard F-Theta lenses will be ready to go into production from January 2018.

The new designs boast improved VIS performance for visual monitoring of the manufacturing process in a range of 1030 to 1080 nanometers. In the 500–680 nanometer range, lens transmission measures over 85 percent and enables direct process monitoring through a simple combination of image sensor and filter.

With a coating for 900 to 1100 nanometers instead of the previous 1030 to 1080 nanometers, the new SilverlineTM lenses for the NIR range are especially suitable for the broader spectra that are typical of diode lasers.

Tim Baldsiefen, Head of Optical Design at Jenoptik Optical Systems is convinced that Jenoptik's significantly expanded portfolio will meet the growing market requirements. "We now have ideal lenses for the most common applications and these lenses are precisely tailored to the specific process characteristics in production. This enables our customers to respond flexibly to production changes."

New motorized beam expander simplifies production steps in laser material processing

The motorized beam expander 1x-8x marks a move by Jenoptik to adapt its portfolio to the market requirements of industry and to focus mainly on the critical parameters of time, quality, and ease of handling.

The new beam expander is offered for wavelengths of 355 or 1030–1080 nanometers. The expansion can be continuously adjusted from 1x to 8x using software commands. In the manufacturing process, changing the expansion of the beam changes its spot size on the workpiece.

The beam can be adjusted to the optimum spot size during the ongoing manufacturing process, resulting in significantly higher quality and productivity for the user. The divergence of the laser beam can be precisely adjusted to achieve tolerance compensation in the entire system, for example to compensate for thermal effects. Controlling the divergence also makes it possible to change the position of the working plane, for instance for 3D processing. Both features – automatic magnification and focusing – help to reduce setup times.

Thanks to an innovative frame concept the construction of the beam expanders is extremely compact and robust. The lenses do not rotate during focusing or magnification but are moved within a linear guide, resulting in excellent beam stability and constantly high quality.

The optical system is designed in such a way that a diffraction-limited image quality is achieved across the entire expansion range. The optimized coatings ensure the highest transmission and minimal thermal effects in wavelength ranges of 355 and 1030–1080 nanometers.

The motorized beam expander is a perfect match for Jenoptik's F-theta lenses and can be used in a large number of beam guidance systems. It is used in the production of microstructures and for the marking and labeling of different materials. It can be easily integrated into any system using the appropriate software interfaces.

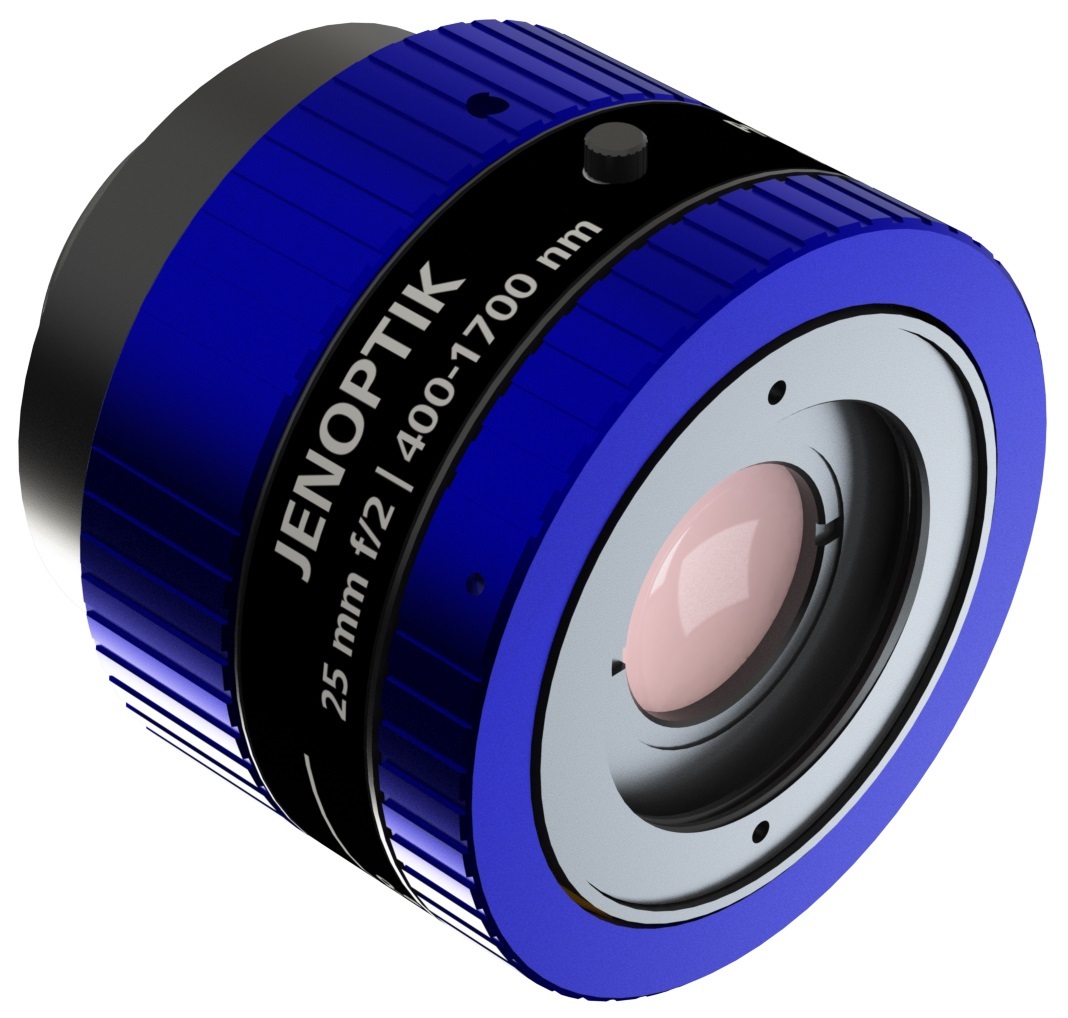

Hyperspectral lens 25mm

New hyperspectral lens with adjustable iris diaphragm to improve the performance of SWIR and hyperspectral cameras

The Jenoptik 25 mm f/2, 400–1700 nm hyperspectral lens (see picture) maximizes the performance of many popular SWIR (shortwave infrared) and hyperspectral cameras. A broad spectral range of 400–1700 nanometers combined with an adjustable diaphragm makes the new lens very versatile. (Download the technical data sheet as PDF)

The standard product lens will enhance image processing across medicine, industrial inspection, surveillance, and law enforcement applications.

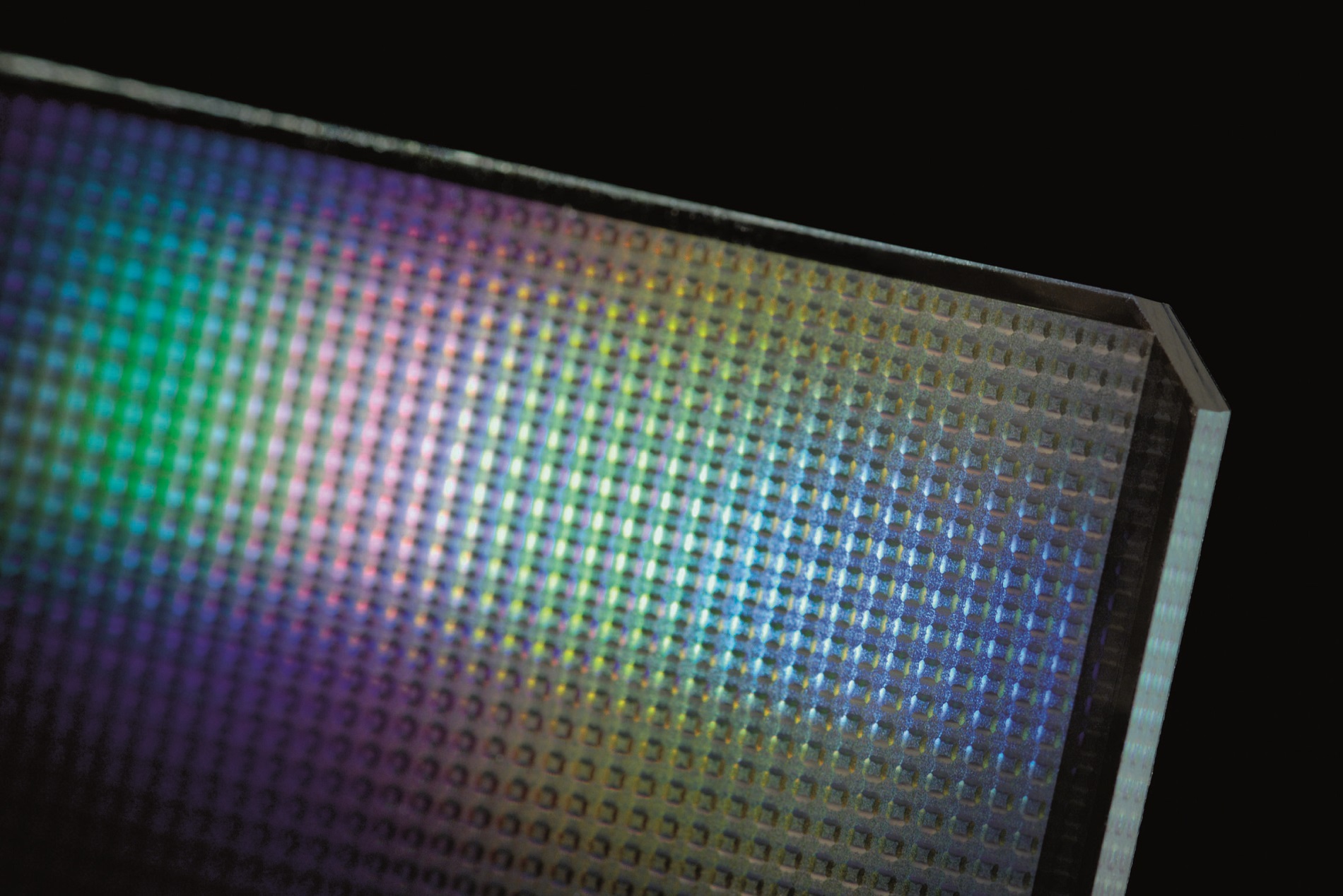

Jenoptik develops enhanced Diffractive Optical Elements (DOEs)

Following the successful market introduction of the efficiency-enhanced Pulse Compression Gratings e2® in 2016, Jenoptik continues to pave the way to performance enhanced diffractive microoptical elements to be used in industrial applications.

The combination of thorough design and state-of-the-art manufacturing technologies, assures tailor-made control of light behavior through diffractive nanostructures. Decades of experience and dedicated know-how in micro-optics, support the customer to find his tailor-made diffractive solution.

In addition to structured light for inspection, augmented reality and biomedical applications, laser material processing is one of the main application field for the improved DOEs. Thanks to high uniformity, precise control of the diffraction orders, reduction of the zeroth diffraction order, Jenoptik's beam shaper/ splitter are key elements to boost processes such as welding, dicing, ablating and drilling.

Jenoptik extensive technologies portfolio enables the production of customized DOEs in small to high volumes, from UV to IR and from low to high power applications.