Jan. 04, 2017

Optical Surfaces Ltd. is a leading manufacturer of high quality aspheric lenses for a wide array of demanding optical applications that involve beam focusing, collimation, expansion or wavefront correction.

Aspheric lenses provide a cost effective way of reducing the number of optical elements in a system. A correctly formed aspheric lens surface may cancel or control spherical aberration. As a result more energy can be concentrated into a smaller area. Aspheric lenses are best suited for low f-number, high throughput applications.

Drawing on its team of skilled technicians and engineers, Optical Surfaces offers fabrication of high performance aspheric lenses up to 600mm diameter in a range of high-quality optical glasses with low f-number to optimise light gathering and focusing performance. To meet the demands of high-power laser focusing, LIDAR and laser launch telescopes Optical Surfaces is routinely able to manufacture aspheric lenses with surface finish of 10/5 scratch/dig, surface roughness of 1nm rms and ultra-smooth slope errors.

A range of high-power laser coatings is available to maintain high transmission and enable the aspheric lenses to operate at the ultra-high energy thresholds demanded by the Terawatt lasers used to investigate fundamental plasma physics.

Optical Surfaces ISO 9001-2008 approved manufacturing facility provides the resources to supply from single specialist requirements to OEM quantities. Benefiting from its stable environment, quality testing becomes quantifiable and reliable. All aspheric lenses produced by Optical Surfaces Ltd. are provided with a complete quality test assurance report.

For further information on high precision aspheric lenses please visit www.optisurf.com or contact Optical Surfaces Ltd.

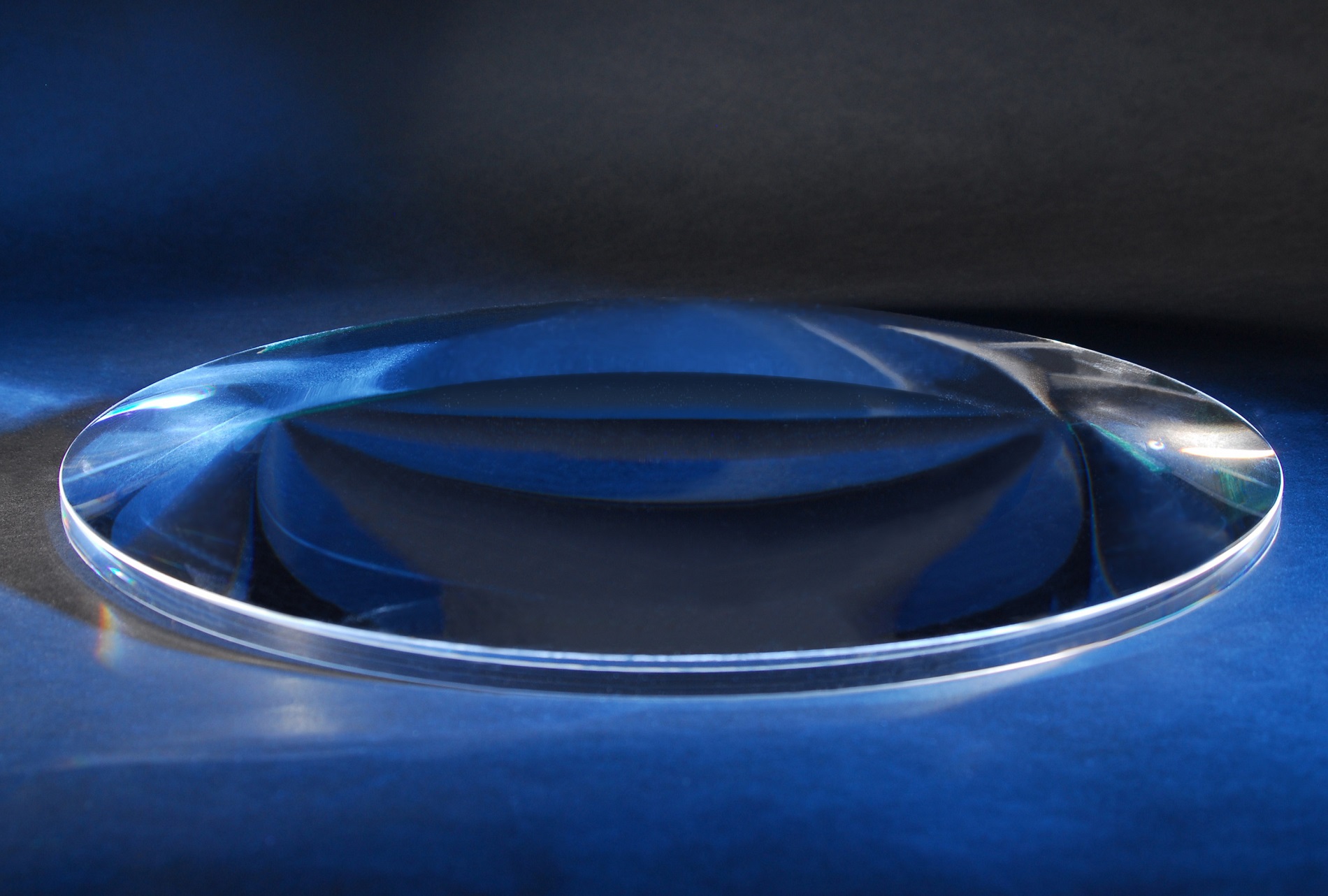

High Throughput Aspheric Lenses

large diameter aspheric lens (courtesy: Optical Surfaces Ltd.)