Nov. 07, 2017

The laser attenuator enables computer-controlled attenuation of a monochromatic light source from 1% – 99% within the wavelength region of ~ 550 nm – 1000 nm. It provides the user with safe, repeatable, and real-time control over the attenuation by combining the LOMA filter with a linear drive, controlled electronics, and dedicated software.

The product specifications of the laser attenuator are:

- USB-controlled

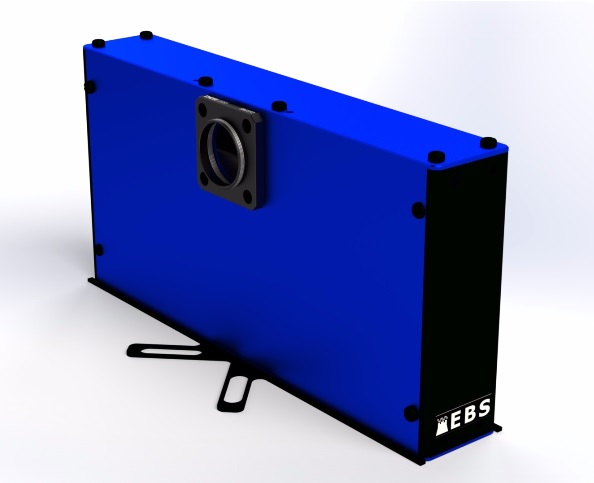

- Small design (173 x 109 x 35 mm³; 400 g)

- Laser attenuation range: 1% to 99%

- Wavelength range ~550 nm – 1000 nm

- No pulse broadening even with femtosecond lasers

- High laser damage threshold

- Durable filter and robust shell

Ultra-Hard Coated, Linear Variable Filter

Delta Optical Thin Film linear variable filters are constructed from wedged optical thin film coatings, that have spectral properties that vary nearly linearly across the length of the filter. The position of the edge of the wavelength can be adjusted by sliding the filter with respect to incident light, and this enables control of the intensity or power of the transmitted laser beam.

The LOMA filter used in the laser attenuator uses a customised version of the standard Delta Optical Thing Film linear variable filters. The design of the LOMA filter has a gradual edge between full transmission and full attenuation.

This filter is based on an optical thin film coating that works on reflection, unlike other filters that work on absorption. This feature allows the LOMA filters to withstand high laser power as it attenuates the laser with no absorption of the input power.

The laser beam is transmitted without distortion of the beam profile, and no extra optics are required. No pulse broadening is observed, even with short laser pulses down to 70 fs. The optical coating works independently of polarisation, and it is designed for a wide range of laser wavelengths between 550 nm and 1000 nm.

Any rejected power is dumped within the unit, and the LOMA is contained within a compact housing equipped with adjustable mountings, which are easy to operate.

Delta Optical Thin Film and Edinburgh Biosciences

The development of the laser attenuator was a result of the successful completion of the Eurostars –Optitune program between Edinburgh Biosciences Ltd and Delta Optical Thin Film.

Delta Optical Thin Film has been producing ultra-hard coated optical filters since 2005, which have the advantages of minimal water uptake, a very smooth surface, increased lifetime, excellent adhesion, and optimal mechanical stability.

These filters are produced with an advanced plasma process, which results in an exceptionally robust filter that can withstand intense light and humidity.

Edinburgh Biosciences incorporated a Delta Optical Thin Film optical filter in their new laser attenuator to enable safe and repeatable attenuation of lasers and other monochromatic sources.

You can purchase the laser attenuator from the Delta Optical Thin Film webshop:

https://www.deltaopticalthinfilm.com/product/laser-attenuator/ or directly via Edinburgh Biosciences.