January 31, 2017

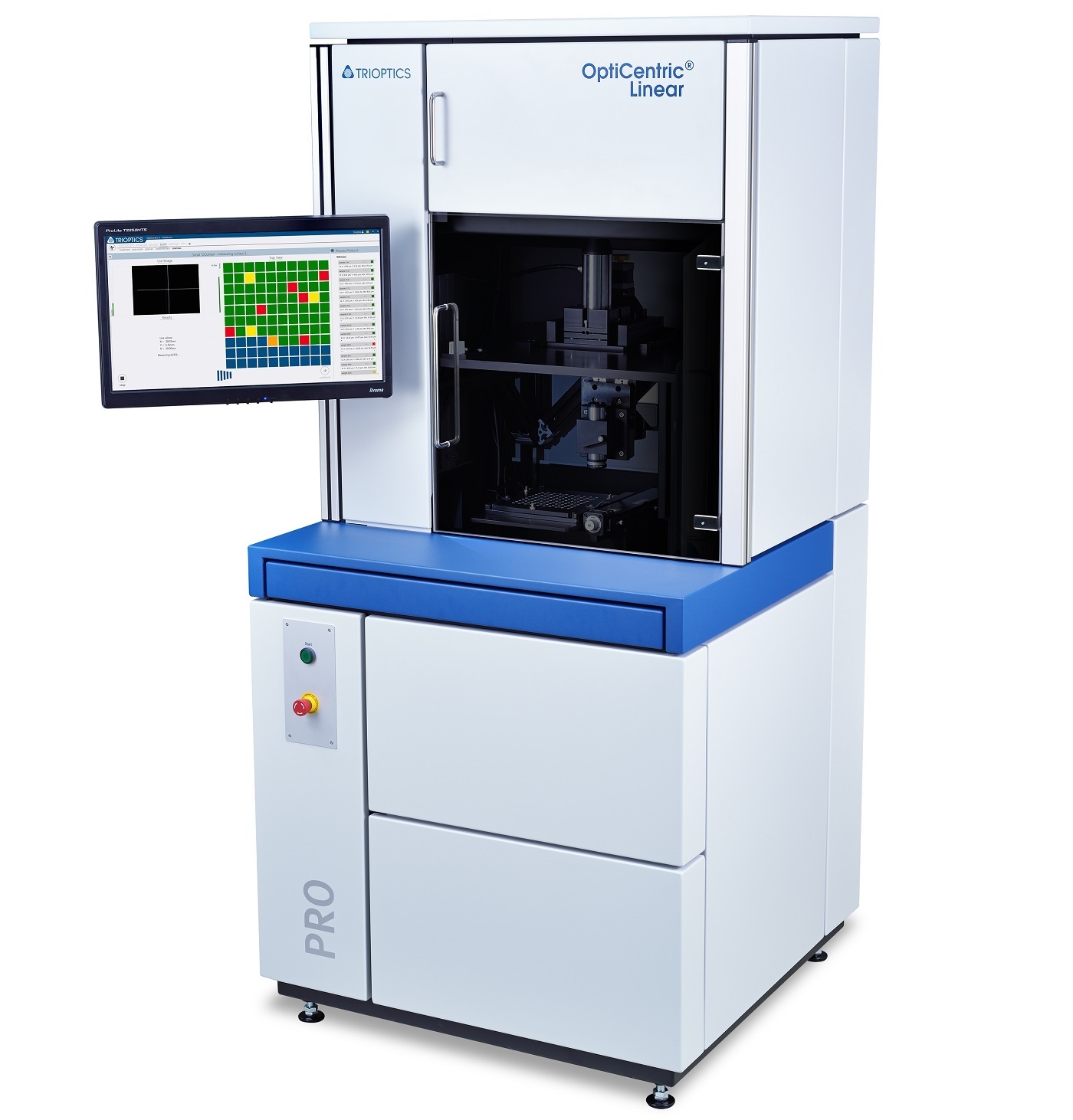

TRIOPTICS GmbH, a leading manufacturer of optical test systems, is revolutionizing the centering measurement of lens systems with its unique OptiCentric® Linear PRO measure-ment system, making productivity increases possible.

The conventional centering test of individual lenses and lens sys-tems only allows the testing of one lens at a time. This is due to the required rotation of the sample that is used to determine the optical axis of a lens, the position of lenses within a system in re-lation to each other and also in relation to the cell.

The presentation of the OptiCentric® Linear PRO at the Photonics West 2017 from January 31 to February 2 in San Francisco, USA, TRIOPTICS will begin a new era of centering tests that allows the qualification of lenses in a series of measurements. This innova-tive development determines the centering of lens systems with-out requiring lens rotation. TRIOPTICS development engineer Felix Hahne explains: “Entire series of lens systems can be posi-tioned on the 150 mm x 150 mm measurement tray and checked in one measurement step. Rotation-free measurement is quick, taking approx. 6.5 seconds for the centering test of a doublet. This means that the system fully meets the requirements for serial and mass production.”

OptiCentric® Linear PRO

The new measurement principle is based on a high-precision linear axis that serves as a reference for the system. In addition, even very small remaining errors are measured, and the measured value is calculated by the software using a correction factor. “The measurement accuracy of less than 1 μm for lens centering errors, paired with the high measurement speed, is remarkable. I am certain that this technology will succeed on the market,” explains Hahne’s colleague, Bernd Lüerß.

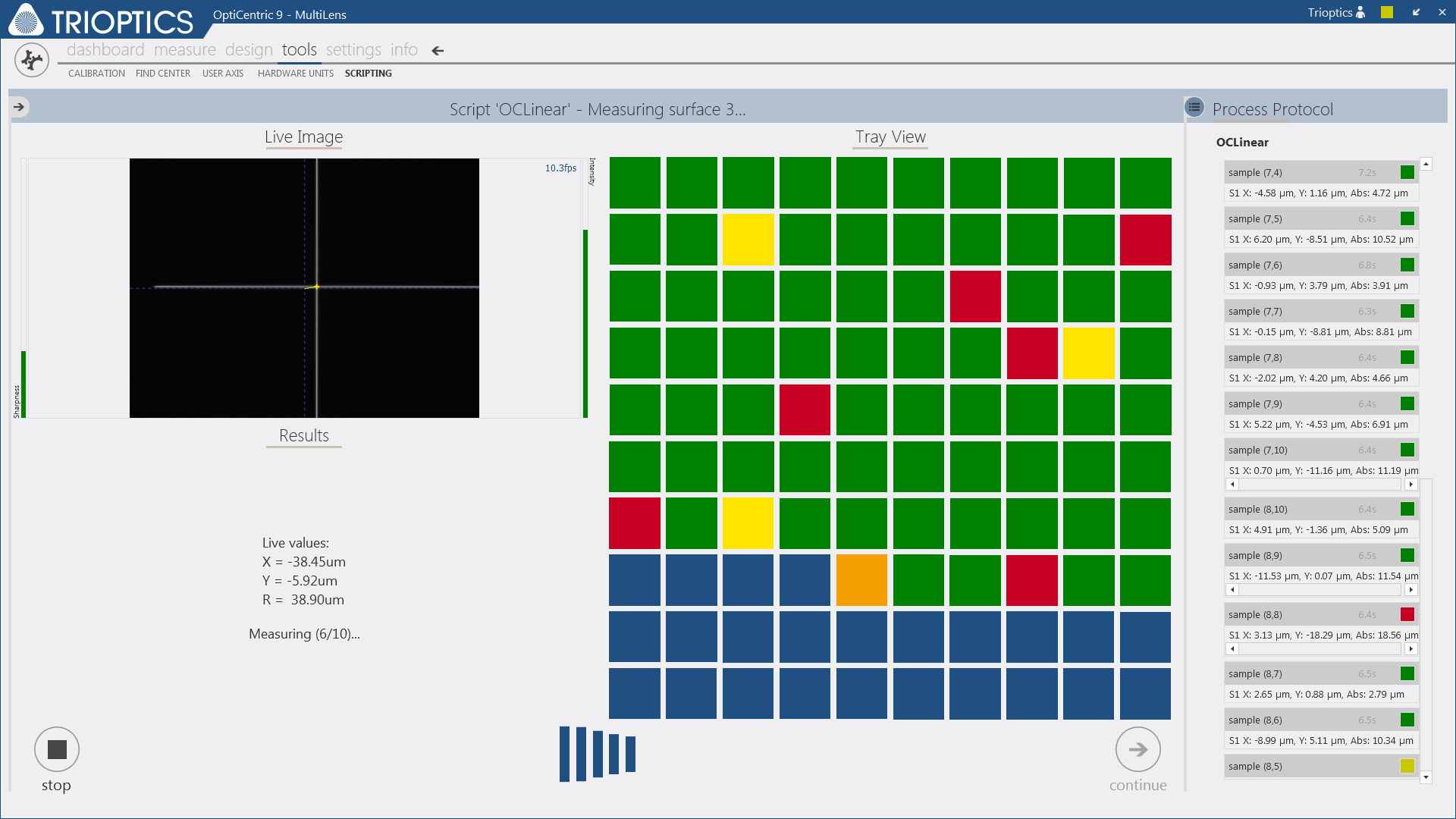

The software has also been extended: In a special adaptation to the production environment, the quality of each lens can be evaluated on the meas-urement tray right there on screen by means of a color code, using pass/fail criteria.