March 29, 2015

ISP Optics Corporation is expanding its DLC coating capabilities on ZnS and IRG26/IG6 materials. ISP Optics has been offering Diamond-Like Carbon (DLC) coatings on Silicon and Germanium for many years. Last year, ISP Optics launched Hybrid DLC coatings on Silicon and Germanium optics to minimize narcissus effect in infrared system. This year, ISP Optics adding DLC coating options for more lightweight materials.

Most LWIR applications are designed for harsh environments: imaging scenes and locations with caustic and staining off-gases and debris, marine environments heavy with salt corrosion and crystal chunks to be cleaned off, severe abrasion from high winds sand-blasting surfaces in the desert. For these types of applications, LWIR optics is required to survive this environment and still maintain good transmission. Diamond-Like Carbon (DLC) coatings were developed for these unforgiving environments.

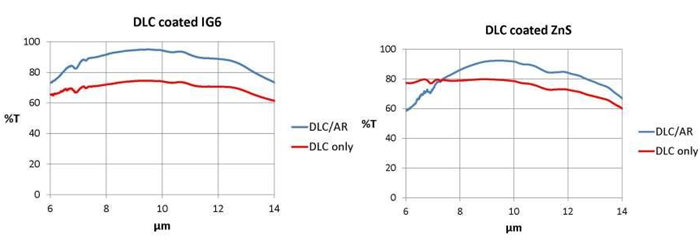

DLC coatings are the toughest coatings available today. DLC coatings have severe abrasion resistance per MIL-C-675/ MIL-F-48616/MIL-C-48497C. They can be subjected to a salt spray per MIL-STD-810F without showing any evidence of deterioration or loss optical performance. With all of this durability, the DLC coatings still provide approximately 90% average transmission and 80% minimum transmission over the 8-12 um range when paired with a high efficiency anti-reflection coating on the back side. These coatings are now available on ZnS and IRG26/IG6 chalcogenide optics. Please see typical transmission curves below.

For the DLC coatings inquiries made from IRG26/IG6 and ZnS materials, please visit:

ISP Optics also provides coating services on customer furnished materials.

ISP Optics Corporation is a vertically integrated manufacturer offering a full range of the infrared products from high performance LWIR Lens Assemblies to catalog and custom infrared optical elements.