October 29, 2014

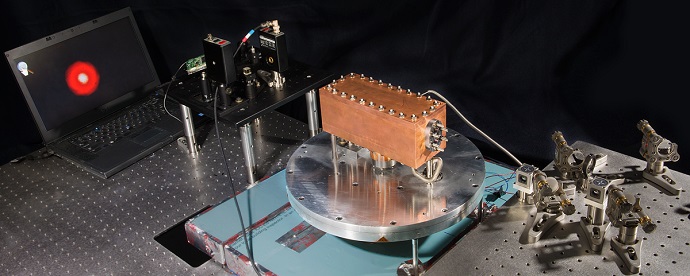

For almost 400 years, mercury gauges have prevailed as the most accurate way to measure pressure. Now, within weeks of seeing “first light,” a novel pressure-sensing device has surpassed the performance of the best mercury-based techniques in resolution, speed, and range at a fraction of the size. The new instrument, called a fixed-length optical cavity (FLOC), works by detecting subtle changes in the wavelength of light passing through a cavity filled with nitrogen gas.

The FLOC system is poised to depose traditional mercury pressure sensors – also called manometers – as the standard used to calibrate commercial equipment, says the interdisciplinary team of NIST researchers who developed the system and will continue to refine it over the next few years. The new design is also a promising candidate for a factory-floor pressure instrument that could be used by a range of industries, including those associated with semiconductor, glass, and aerospace manufacturing [see "Industrial Applications"].

“We’ve exceeded the expectations we had three years ago,” says Thermodynamic Metrology Group Leader Gregory Strouse. “This device is not only a photonic sensor, it’s also a primary standard. It’s the first photonic-based primary pressure standard. And it works.”

About the size of a travel mug, the FLOC has a resolution of 0.1 mPa (millipascal or thousandths of a pascal), 36 times better than NIST’S official U.S. pressure standard [see "FLOC vs. Mercury Standard"], which is a 3-meter-tall (about 10-foot) column of liquid mercury that extends through the ceiling of the calibration room.

The cavity’s range also beats that of the mercury manometer at the low end, “an impressively wide range” that stretches from the millipascal- to hundred thousand pascal-level, says Principal Investigator Jay Hendricks of the Thermodynamic Metrology Group. “There’s no other instrument that can handle so many different ranges and have that high a resolution,” he continues.

The FLOC is 100 times faster than the standard mercury manometer, too.

“It can do in a second what the big mercury manometer takes about a minute and a half to do,” Hendricks says.

Traditional pressure sensors rely on changes to the height of a column of mercury [see "How Tall"],which rises or falls in response to pressure. But though accurate and reliable, these instruments are bulky and their dependence on mercury, a neurotoxic substance, makes them undesirable. In fact, mercury’s hazards have prompted a global effort to cut or phase out this substance from products and manufacturing, a goal made manifest by a United Nations Environment Program (UNEP) treaty that has been signed by more than 100 countries.

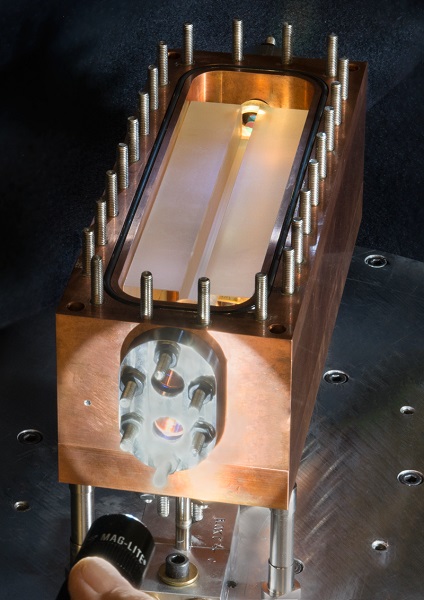

The new, mercury-free, photonic pressure sensor consists of a temperature-controlled optical cavity [see "A Degree of Control"] approximately 15.5 cm (about 6 inches) long by 5 cm (2 in) by 5 cm (2 in) encased in copper. The cavity contains two channels, one flooded with nitrogen gas and the other in vacuum. A beam of low-power red (633-nm) laser light is “locked” to each channel, meaning it forms a standing wave that self-synchronizes through constant adjustments to its wavelength [see "Standing Waves"]. Some of the light from each channel is allowed to exit the FLOC, where the beams combine to form an interference pattern.

A change in pressure does not affect the light in the vacuum tube because there is no medium to be affected. But it does affect the density of the nitrogen, which in turn alters the gas’s index of refraction or how fast light travels through it. And this change in light speed affects the wavelength of the light resonating in the nitrogen-filled channel. Though these alterations in wavelength are minute – on the picometer level, a hundred times smaller than an atom – they can be detected in the interference pattern.

The FLOC inside its copper container with the cover removed, revealing the upper of the two channels.

So far the technique is accurate to within 0.005% or 50 parts per million (ppm), which makes it superior to most commercial pressure instruments. But this is only a first attempt and Hendricks and his colleagues believe they can do better. In the next three years, the team will try to drive this accuracy below the 5 ppm range [see "Lowering Uncertainties via VLOC"], which will allow it to surpass that of the current manometer standard.

Hendricks and Strouse see great potential for making the system smaller too – perhaps as small as a smartphone someday – while further increasing its speed and resolution. “There are tricks we haven’t even begun to tap into yet,” Hendricks says.

-- Jennifer Lauren Lee