December 9, 2013

BY BJORN CAREY

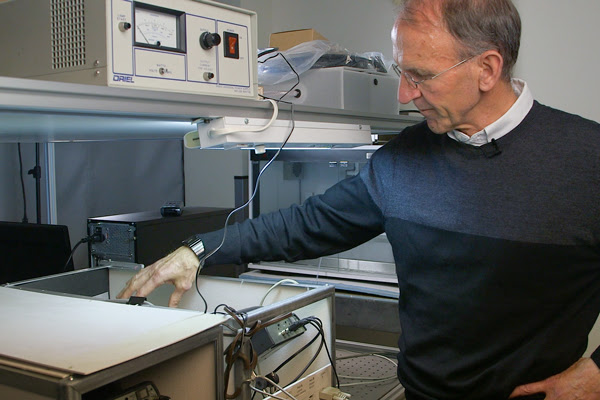

For the past three years, two of Lambertus Hesselink's graduate students have been planning, building and calibrating a nano-conveyor belt. The one-of-a-kind experiment is about the size of a billiard table, and consists of lasers, mirrors, microscopes and computers that form a set of optical tweezers that can manipulate individual nanoparticles.

The expertise and cost associated with such a device would typically put it beyond the reach of most students. Now, though, Hesselink and his students have developed a method for digitizing the physical experiment and uploading it to the Internet, making it available to millions of people at a time.

Hesselink, a professor of electrical engineering, and by courtesy of applied physics and aeronautics and astronautics at Stanford, said that the approach could solve the long-standing issue of incorporating lab work with the teaching available through massive open online courses, or MOOCs.

"If you're going to earn a science or engineering degree in a MOOC, I think that you will need to fulfill some sort of lab requirement," Hesselink said. "This could be a very effective way to share expensive and complicated laboratories with the masses to meet that requirement."

Virtual labs for online education

The virtual labs are Hesselink's latest effort to bring advanced laboratories to the masses online, an approach he pioneered in 1996. That first version included several then-new features, such as remote control and scheduling of the lab, chat, faculty support and an electronic notebook. The most recent "lab in a box" generation of iLabs involved automated hardware that students could access through the Internet and control remotely from anywhere in the world. The labs took up only a few cubic feet of space, which significantly lowered operating costs compared to traditional setups.

The overwhelming popularity of MOOCs, however, made this arrangement challenging.

Although remote-access automated labs work well for courses with small enrollment – indeed, several online courses offered by Stanford have thrived using remote labs or inexpensive or free send-home Arduino kits – Hesselink wanted to find a way to scale that experience to accommodate courses of 100,000 or more students.

If 100,000 students in a course took turns running even a very basic, 15-minute diffraction experiment, it would take more than 1,000 days for each student to get a turn. The logjam becomes even more severe when all those students need individual access to a "wet" lab; the materials required to conduct chemistry or biology experiments would constantly need to be replenished.

To accommodate classes of tens of thousands of students in a more reasonable amount of time, Hesselink said, you would need to increase the number of automated labs, and doing so could cut into the cost efficiencies that made the labs attractive in the first place.

The solution, Hesselink came to realize, was to eliminate the moving parts.

Just as good as the real thing

This summer, the team consisting of Hesselink; Lars Thorben Neustock, a summer research fellow from Germany; and George Herring, a visiting summer researcher, designed a small diffraction experiment – consisting of two lasers, a diffraction grating, multiple lenses and more – that fit in a box the size of a picnic basket.

Then, they ran an automation program that moved the devices into each possible configuration, and tested them at every possible power level. As this occurred, a built-in LabVIEW unit – a standard camera and software suite for controlling, observing and recording experiments by computer – took a snapshot of each experimental setup and the corresponding result. These images and data were annotated and logged into a database.

Now, users can log into the database and interact with the same controls and video view as would be used during a real experiment, but when students change the laser color from blue to red, they're observing the prerecorded state.

"They're seeing the exact same diffraction experiment and controlling it the same way as they would with the widely used LabVIEW program," Hesselink said. "It's the same experience if you're sitting in a lab here at Stanford or at a computer in Africa."

Transforming a physical experiment into a virtual one requires relatively little effort, said Neustock. A diffraction experiment like the prototype takes just a few hours to automate a few hundred states and record the results. "And then you have it forever," he said.

Capturing the nano-conveyor belt experiment – which is significantly more complex than the prototype experiment, and was never set up with iLabs compatibility in mind – required only two small modifications and was done in an afternoon's time.

Hesselink said that the ease and success of transforming these two physical labs into virtual experiments shows that the new approach could help iLabs overcome the entry barriers – namely affordability and access – that, despite broad interest, hindered the scalability of previous iterations of iLabs.

Beyond use in MOOCs or real-life classrooms, Hesselink suggested that iLabs could be used to publish PhD students' experiments and preserve them for future generations. He also speculated that the ability to conduct low-risk, low-cost experiments through iLabs could one day have commercial applications in medicine, engineering and science.

Labs for the masses

The ease of adapting intricate setups could allow scientists – and hopefully motivate them – to build a robust library of virtual experiments in a short time.

"The best part is that this is very scalable," Hesselink said. "You could offer universities free access to the database if they agreed to upload their automated experiments. You can imagine filling a hard drive with 100 or 1,000 experiments and giving it to a school that doesn't have any access to equipment. Or you could put it on Google's servers, and millions of people could access a single experiment at the same time."

It also requires significantly less maintenance, Hesselink said, which opens the door to chemistry and biology experiments. (Such experiments would include mistakes, Hesselink said, because errors have great educational value.)

Hesselink said that some scientists will argue that iLabs can't replace a hands-on experience for certain experiments, but he thinks that the advantages far outweigh this negative. Using the actual high-powered lasers in the nano-conveyor belt, for instance, require significant training and safety measures. Accessing a virtual replication of the experiment will provide novice students unprecedented access to explore advanced setups.

Pedagogical studies have shown that students highly value iLabs, Hesselink said. Students who never had an intention to become involved in experiments found iLabs highly motivating to study science and engineering. For instance, Optics 4 Kids, a website of the Optical Society that ran the Stanford iLabs until the mid-2000s, was well frequented by students worldwide and received very favorable feedback.

"We're very fortunate at Stanford to have access to so many wonderful pieces of equipment," Hesselink said. "This is a nice way to spread that experience."

Professor Lambertus Hesselink's new iLab could solve the long-standing issue of incorporating lab work with the teaching available through MOOCs.

Video by Kurt Hickman