October 13, 2016

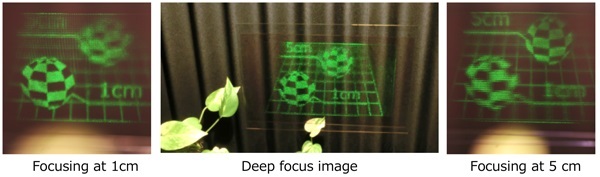

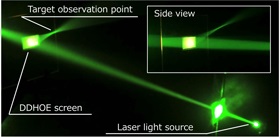

NICT has newly developed a projection-type see-through holographic 3D display technology, in which an optical screen of a digitally designed holographic optical element (DDHOE) and a digital holographic projection technique were combined. Holographic 3D image reconstruction was successfully demonstrated via the see-through screen to a target observation area [see Fig. 1].

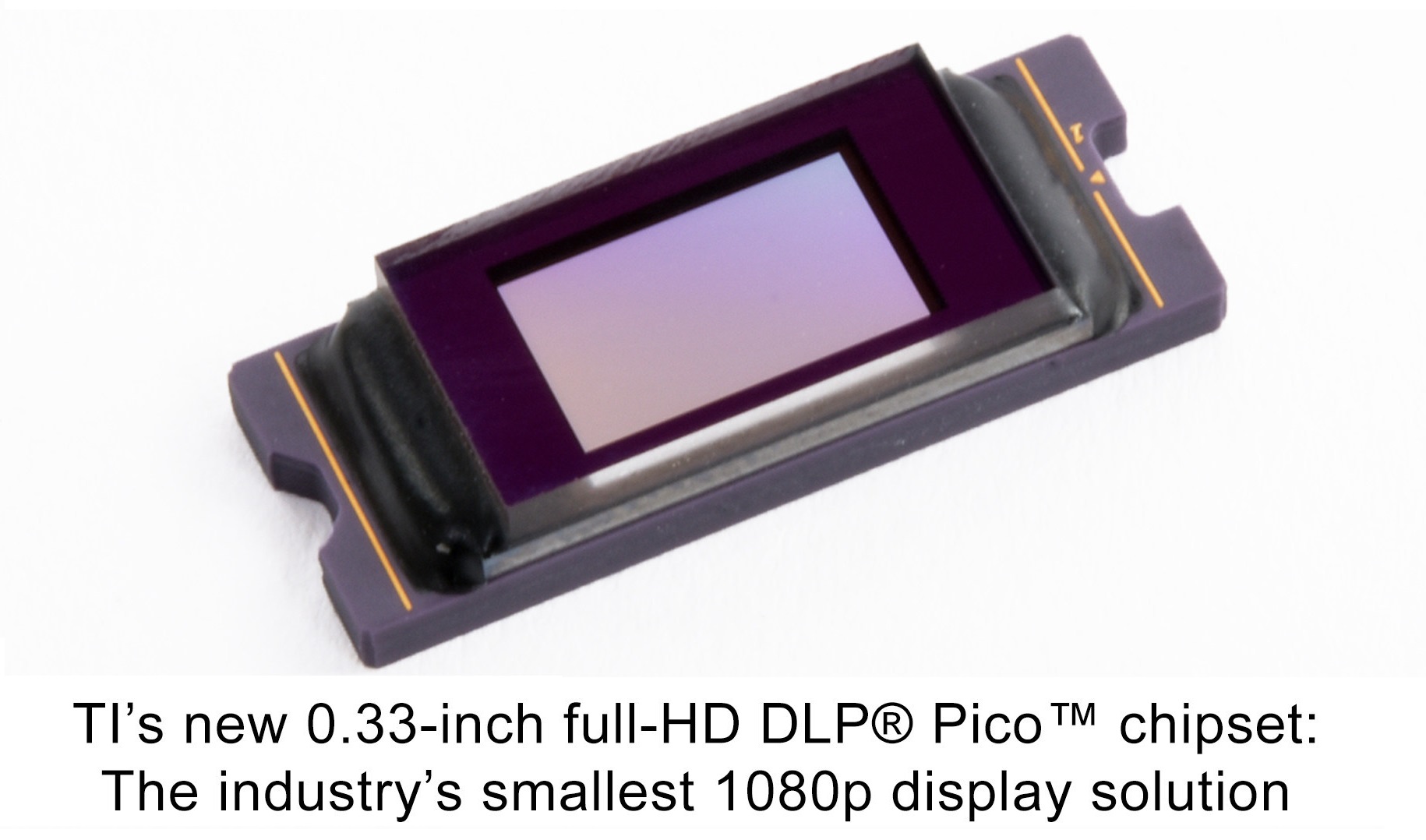

Basically, dynamic holographic 3D display technology faces the severe limitation of the spatial-temporal resolution of the spatial light modulator (SLM) to realize a practical display size and visual angle. Moreover, the general system design of holographic 3D displays requires a large optical setup behind the display window.

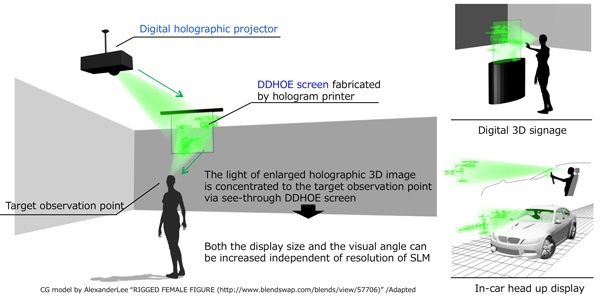

In this work, a holographic 3D image was largely projected to a see-through screen of DDHOE by using the digital holographic projection technique. The screen was fabricated using a hologram printer, which was uniquely developed by NICT. The light of the enlarged holographic 3D image was then concentrated to a target observation area by an appropriately designed reflection function to increase the visual angle. Because this technology can have a high degree of freedom of both the display size and the visual angle independently, and also a high usability of the see-through display system, it will accelerate the adoption of holographic three-dimensional displays in industrial applications, such as digital signage, in-car head-up displays, smart-glasses and head-mounted displays.

A part of this work was published in Nature Communications on October 3, 2016. This work was supported by JSPS KAKENHI (Grant nos. 26790064 and 16H01742), the MIC/SCOPE (Grant no 162103005) and the Centre of Innovation Program from the Japan Science and Technology Agency, JST.

Thanks to the advancements of high-speed computing and communication technology, we can now deal with huge amounts of data, and thus a display technology that finally shows output information is becoming increasingly important. In particular, the demand for a dynamic 3D display technology is increasing with the advancement of 3D printing/scanning technologies. At NICT, several dynamic holographic 3D displays have been developed [1,2]. However, general holographic 3D displays suffer a trade-off between the display size and the visual angle to view the entire display area owing to the severe limitation of the spatial-temporal resolution of current SLMs.

Achievements

The newly developed projection-type see-through holographic 3D display technology, allows to design freely both the display size and the visual angle independently of see-through holographic 3D image reconstruction.

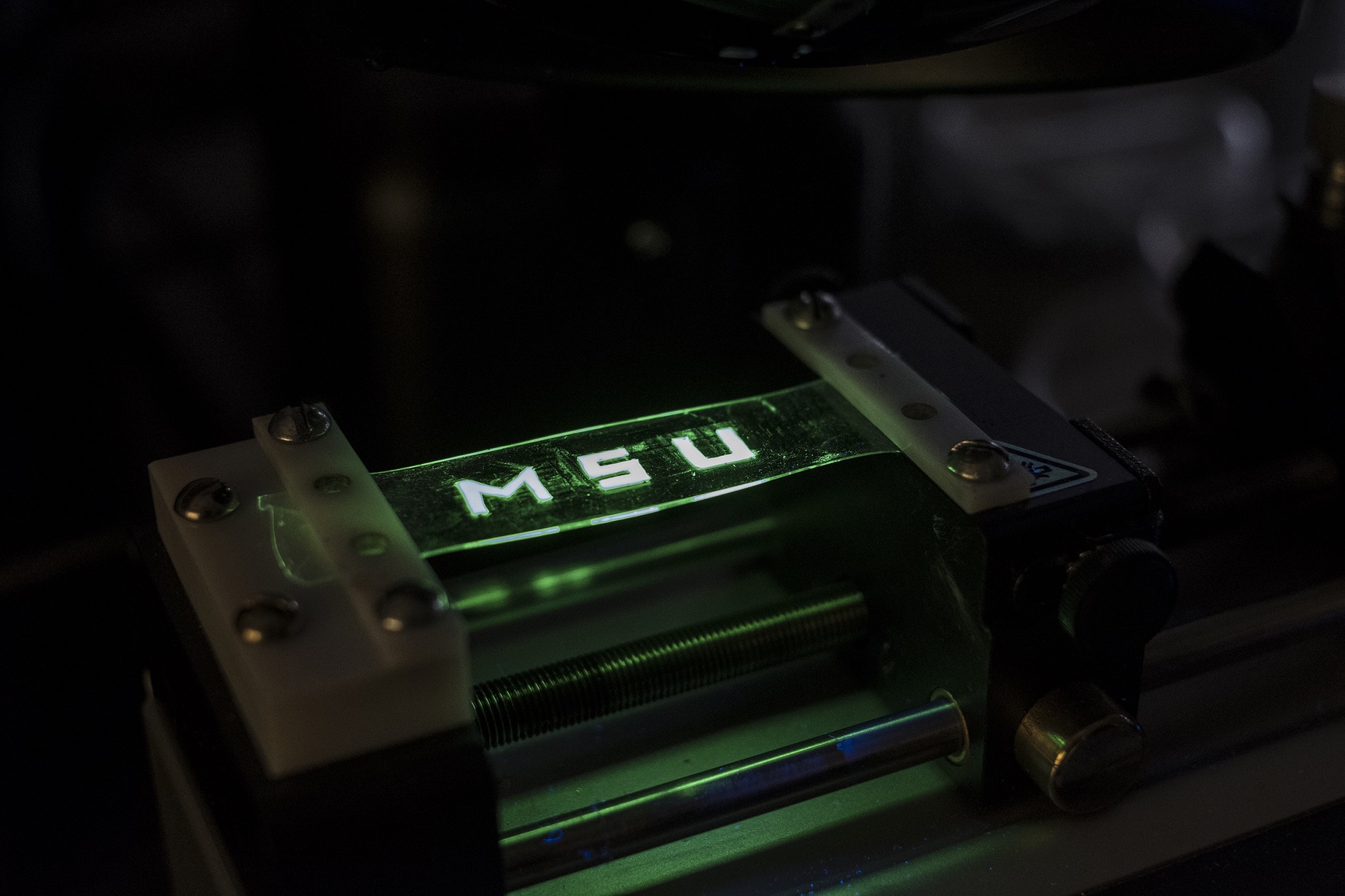

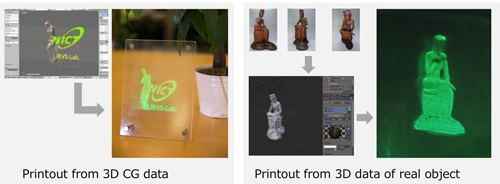

For the purpose of creating a new optical technology, the Electromagnetic Application (EMA) laboratory in NICT started the holographic printing technology (“HOPTECH”) project in 2014. As a part of this project, a hologram printer for recording a digitally designed wavefront was developed. This printer can not only print 3D data for 3D visualization [see Fig. 3] but also fabricate a holographic optical element (HOE) with an arbitral reflection function (we call this kind of hologram a digitally designed holographic optical element (DDHOE)).

Fig. 2 Concept of this approach and some examples of application

A new approach was achieved using two key technologies: digital holographic projection to enlarge the display size and fabrication of an optical screen of DDHOE that reflects the light of a projected holographic 3D image to a target observation area to increase the visual angle [see Fig. 2]. A digital holographic projector was developed by modifying NICT’s previous holographic 3D display system[1] with a projection lens. The appropriate reflection function, namely, the function to concentrate the light of a projected holographic 3D image to the target observation area, of DDHOE was once calculated as wavefront information (amplitude and phase distribution of the light) considering the projection parameters. The wavefront of that reflection function was then implemented into a holographic recording film by using a hologram printer.

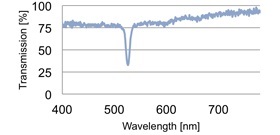

In comparison with conventional approaches that use a concave mirror or a convex lens to increase the visual angle of a holographic 3D image, the new approach can achieve a higher degree of freedom of display size and visual angle. These parameters are important for practical display use, by using only a thin film of DDHOE [see Fig. 4]. Additionally, this film has high transparent characteristics at visible light wavelength [see Fig. 5]; this work will open up the real holographic 3D display of some applications such as in-car head-up displays, smart glasses, head-mounted displays and digital signage [see Fig. 2].

Future work

NICT will optimize the full-color display system by upgrading the hologram printer. Multiple holographic projections from different incident directions to the DDHOE will also be focused on to extend the observation area.

Fig. 3 Examples of hologram printing technique

Fig. 4 Optical characteristic of DDHOE screen

Fig. 5 Transmission curve of DDHOE screen

References

[1] Senoh, T. et al. Wide viewing-zone angle full-color electronic holography system using very high resolution liquid crystal display panels. Proc. SPIE 7957, 795709 (2011).

[2] Sasaki, H. et al. Large size three-dimensional video by electronic holography using multiple spatial light modulators. Sci. Rep. 4, 6177 (2014).

Journal Information

Journal: Nature Communications, DOI: 10.1038/ncomms12954

URL: http://www.nature.com/ncomms/2016/161003/ncomms12954/full/ncomms12954.html

Title: Projection-type see-through holographic three-dimensional display

Authors: K. Wakunami, P.-Y. Hsieh, R. Oi, T. Senoh, H. Sasaki, Y. Ichihashi, M. Okui, Y.-P. Huang & Kenji Yamamoto