05 August 2013

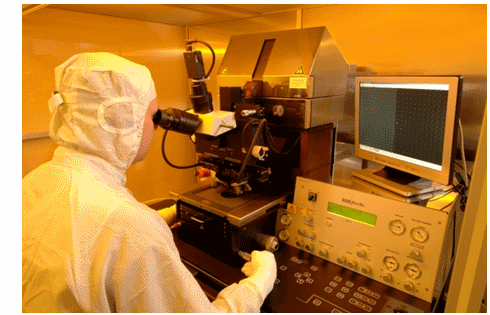

Extreme purity is a basic prerequisite in the production of semiconductors. The production of minuscule semiconductor components requires a cleanroom to minimize contamination from airborne particles and chemicals. In the past few years, improved technologies have already contributed considerably to reducing the problem of disturbing dust particles. The semiconducting components, however, are becoming ever smaller, which makes the airborne contamination of cleanrooms by chemical substances (the so-called "Airborne Molecular Contamination" (AMC)) a serious challenge. Even the smallest molecular concentrations can cause damage. Now, new laser-based methods, with which AMC can be measured, are investigated within the scope of a European project in which the Physikalisch-Technische Bundesanstalt (PTB) is involved. In a preliminary study, the most important contaminants were identified, which will be further studied in this project.

They can occur in furniture and leak out of certain floorings, and they disturb sensitive production processes in semiconductor manufacturing: airborne substances such as, e.g., ammonia and formaldehyde. In a study conducted within the scope of a new research project on the monitoring of the air quality in cleanrooms, these two substances were identified as important substances in the manufacturing of semiconducting microstructures on which the project will focus. "Ammonia adheres to everything and can thus be easily carried into the cleanroom from the outside", explains Anne Rausch from PTB. "Furthermore, it may sometimes also be a product of the manufacturing processes in the cleanroom itself."

The European cooperation project, which has now been launched, aims to study methods allowing the concentration of such substances to be monitored in real time in the air of cleanrooms. "In the event of an AMC increase, production can be interrupted. The components concerned can be checked and, if necessary, be discarded", explains A. Rausch.

Hereby, the aim is to achieve real-time measurements at a detection limit in the range of a few AMC particles in a billion of particles (ppb) within the scope of this project. For this purpose, it is planned to compare cutting-edge laser-spectroscopic methods with regard to their applicability to AMC measurements, and then to optimize them for AMC monitoring. PTB studies, in close cooperation with Dutch and Finnish scientists, the applicability of photoacoustic spectroscopy and cavity ring-down spectroscopy (CRDS). European partner institutes in the UK, Italy and the Czech Republic are checking the suitability of other measurement methods.

In addition, the project aims to manufacture reference samples. These are AMC concentrations which have been measured with great accuracy and can be used to calibrate measuring instruments.

"MetAMC – Metrology for airborne molecular contamination in manufacturing environments"

Apart from PTB, the metrological partner institutes from Finland, the Czech Republic, Italy, the UK, the Netherlands as well as the University of Turin and the Taiwan-based company HCP have gathered to tackle this project. The European Union is funding the project with a total amount of 2.9 million euros within the scope of the European Metrology Research Programme (EMRP). The results of the project will be made available to European partners in the semiconductor industry, among other things in the form of "Good Practice Guides" for AMC measurements. The results will be presented to interested participants within the scope of a workshop which will take place at the end of the project. Information with regard to registration will be provided on the project's website in due time. In order to protect the investment made by the European industry, the results from this project which are directly exploitable from a commercial viewpoint will be patented.

For further information on the project, please visit: