September 16, 2013

By Steve Koppes

A multi-institutional team of engineers has developed a new approach to the fabrication of nanostructures for the semiconductor and magnetic storage industries. This approach combines top-down advanced ink-jet printing technology with a bottom-up approach that involves self-assembling block copolymers, a type of material that can spontaneously form ultrafine structures.

The team, consisting of nine researchers from the University of Illinois at Urbana-Champaign, the University of Chicago and Hanyang University in Korea, was able to increase the resolution of their intricate structure fabrication from approximately 200 nanometers to approximately 15 nanometers. A nanometer is a billionth of a meter, the width of a double-stranded DNA molecule.

The ability to fabricate nanostructures out of polymers, DNA, proteins and other “soft” materials has the potential to enable new classes of electronics, diagnostic devices and chemical sensors. The challenge is that many of these materials are fundamentally incompatible with the sorts of lithographic techniques that are traditionally used in the integrated circuit industry.

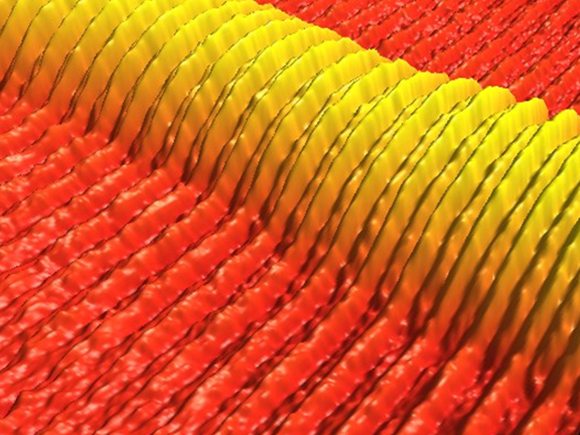

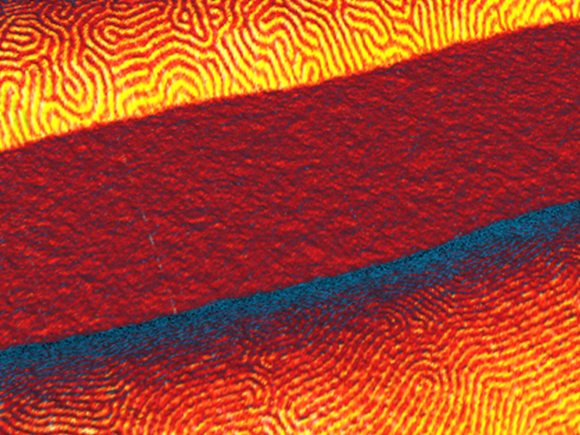

This atomic force microscope image shows two different printed lines of block copolymers, colored and scaled by the microscope’s software. Each block copolymer has a different molecular weight and therefore has a different size and spacing of its structural components. The repeating structures at left have a spacing of 41 nanometers, while those at right have spacing of 27 nanometers.

Courtesy of Serdar Onses/University of Illinois-Urbana

Recently developed ultrahigh resolution ink-jet printing techniques have some potential, with demonstrated resolution down to 100-200 nanometers, but there are significant challenges in achieving true nanoscale dimension. “Our work demonstrates that processes of polymer self-assembly can provide a way around this limitation,” said John Rogers, the Swanlund Chair Professor in Materials Science and Engineering at Illinois.

Rogers and his associates report their findings in the September issue of Nature Nanotechnology. Combining jet printing with self-assembling block copolymers enabled the engineers to attain the much higher resolution, as suggested by lead author Serdar Onses, a postdoctoral scientist at Illinois. Onses earned his doctorate at the University of Wisconsin under Paul Nealey, now the Brady W. Dougan Professor in Molecular Engineering at UChicago and a co-author of the Nature Nanotechnology paper. “This concept turned out to be really useful,” Rogers said.

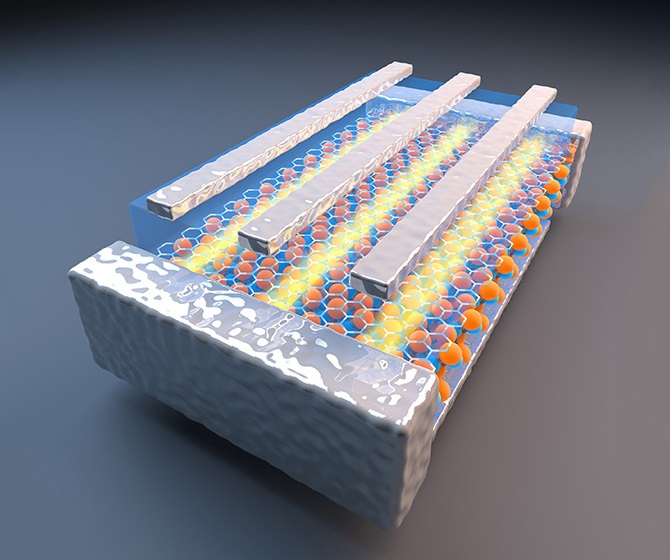

Researchers painted this butterfly image made out of block copolymer films using electrohydrodynamic jet printing. The film consists of intricately printed components of two differing molecular weights, which display different sizes and spacing at scale of tens of nanometers (one-billionth of a meter). The butterfly at its widest diameter at the wingtips measures approximately 250 microns, the width of a few human hairs sitting snugly side by side.

Courtesy of Serdar Onses/University of Illinois-Urbana

Engineers use self-assembling materials to augment traditional photolithographic processes that generate patterns for many technological applications. They first create either a topographical or chemical pattern using traditional processes. For the Nature Nanotechnology paper, this was done at imec in Belgium, an independent nanoelectronics research center. Nealey’s laboratory pioneered this process of directed self-assembly of block copolymers using chemical nanopatterns.

Nearing the limits

The resolution of the chemical pattern nears the current limit of traditional photolithography, noted Lance Williamson, a graduate student in molecular engineering at UChicago and co-author of the Nature Nanotechnology article. “Imec has the capability to perform the photolithography at this scale over large areas with high precision,” Williamson said.

Back at the University of Illinois, engineers place a block copolymer atop this pattern. The block copolymer self-organizes, directed by the underlying template to form patterns that are at much higher resolution than the template itself.

Previous work has focused on the deposition and assembly of uniform films on each wafer or substrate, resulting in patterns with essentially only one characteristic feature size and spacing between features. But practical applications may need block copolymers of multiple dimensions patterned or spatially placed over a wafer.

“This invention, to use inkjet printing to deposit different block copolymer films with high spatial resolution over the substrate, is highly enabling in terms of device design and manufacturing in that you can realize different dimension structures all in one layer,” Nealey said. “Moreover, the different dimension patterns may actually be directed to assemble with either the same or different templates in different regions.”

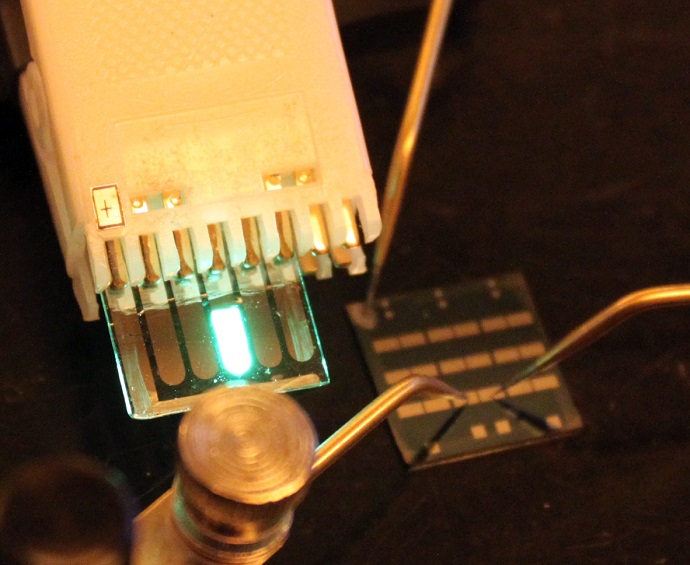

A technician sits at a track system at imec Belgium, an independent nanoelectronics research center. The system coats, bakes and develops thin polymer films on silicon wafers. They are critical steps in the fabrication of samples that imec provides to Prof. Paul Nealey’s research group at the University of Chicago’s Institute for Molecular Engineering.

Copyright IMEC

Benefits of e-jet printing

The advanced form of ink-jet printing the engineers use to locally deposit block copolymers is called electrohydrodynamic, or e-jet printing. It operates much like the ink-jet printers office workers use for printing on paper. “The idea is flow of materials from small openings, except e-jet is a special, high-resolution version of ink-jet printers that can print features down to several hundred nanometers,” Onses said. And because e-jet can naturally handle fluid inks, it is exceptionally well-suited for patterning solution suspensions of nanotubes, nanocrystals, nanowires and other types of nanomaterials.

“The most interesting aspect of this work is the ability to combine ‘top-down’ techniques of jet printing with ‘bottom-up’ processes of self-assembly, in a way that opens up new capabilities in lithography—applicable to soft and hard materials alike,” Rogers said.

“The opportunities are in forming patterned structures of nanomaterials to enable their integration into real devices. I am optimistic about the possibilities.”