July 3, 2013

The following is an excerpt from an article that appeared in Chemistry World (published by the Royal Society of Chemistry, UK) on July 3, 2013. It describes research by Harvard SEAS graduate student Sam Felton, Robert J. Wood (Charles River Professor of Engineering and Applied Sciences at SEAS), Daniela Rus (of MIT), and coauthors at SEAS, Worcester Polytechnic Institute, and MIT.

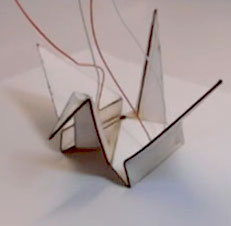

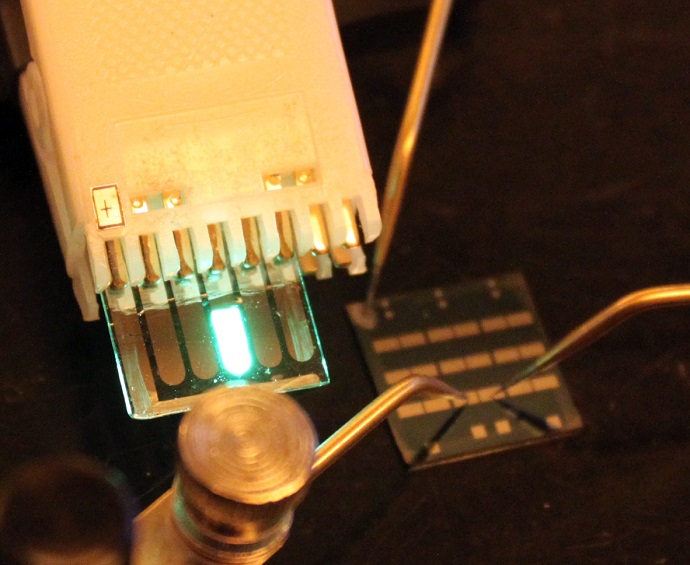

Scientists in the US have developed flat pack structures that can autonomously assemble into three-dimensional shapes on application of an electrical current. Unlike traditional three-dimensional assembly techniques, which require sophisticated printers to reach the final product, this approach uses heat triggered shape memory polymers.

Three-dimensional structures normally come pre-assembled or equipment needs to be transported to create them in situ. Now, along with his colleagues, Samuel Felton, from Harvard University, has demonstrated that by printing shape memory polymers (SMP) onto laser-cut joints with conductive coatings, the assembly process can be separated entirely from the original printing.