January 22, 2014

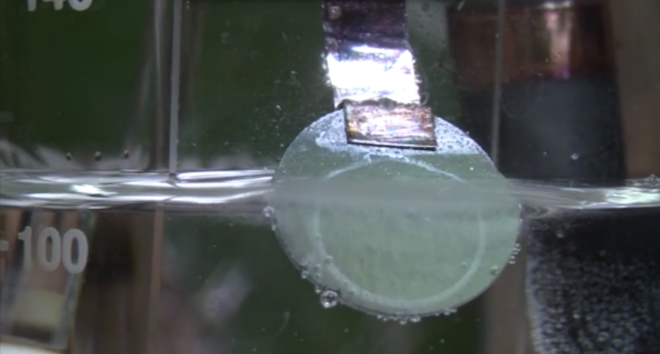

Researchers at North Carolina State University have shown that a one-atom thick film of molybdenum sulfide (MoS2) may work as an effective catalyst for creating hydrogen. The work opens a new door for the production of cheap hydrogen.

Hydrogen holds great promise as an energy source, but the production of hydrogen from water electrolysis – freeing hydrogen from water with electricity – currently relies in large part on the use of expensive platinum catalysts. The new research shows that MoS2 atomically thin films are also effective catalysts for hydrogen production and – while not as efficient as platinum – are relatively inexpensive. (A Q&A with Cao on how this research differs from earlier studies of other catalysts for hydrogen production can be found on NC State’s research blog.)

“We found that the thickness of the thin film is very important,” says Dr. Linyou Cao, an assistant professor of materials science and engineering at NC State and senior author of a paper describing the work. “A thin film consisting of a single layer of atoms was the most efficient, with every additional layer of atoms making the catalytic performance approximately five times worse.”

The effect of the thin films’ thickness came as a surprise to researchers, because it has long been thought that catalysis normally takes place along the edges of the material. Because thin films have very little ‘edge,’ conventional wisdom held that thin films were essentially catalytically inactive.

But the researchers discovered that a material’s thickness is important because the thinner the MoS2 thin film is, the more conductive it becomes – and the more conductive it becomes, the more effective it is as a catalyst.

“The focus has been on creating catalysts with a large ‘edge’ side,” Cao says. “Our work indicates that researchers may want to pay more attention to a catalyst’s conductivity.”

Cao developed the technique for creating high-quality MoS2 thin films at the atomic scale in 2013. The current production of hydrogen from the atomically thin film is powered by electricity. His team is working to develop a solar-powered water-splitting device that uses the MoS2 thin films to create hydrogen.

The paper, “Layer-dependent Electrocatalysis of MoS2 for Hydrogen Evolution,” is published online in Nano Letters. Lead author of the paper is Yifei Yu, a Ph.D. student at NC State. Co-authors include Yanpeng Li, a Ph.D. student at NC State; Dr. Shengyang Huang, a former visiting scholar at NC State; and Drs. Stephan Steinmann and Weitao Yang of Duke University. The research was supported by U.S. Army Research Office grant W911NF-13-1-0201.

The study abstract

“Layer-dependent Electrocatalysis of MoS2 for Hydrogen Evolution”

Authors: Yifei Yu, Shengyang Huang, Yanpeng Li, and Linyou Cao, North Carolina State University; Stephan Steinmann and Weitao Yang, Duke University

Published: Jan. 16, 2014, Nano Letters

DOI: 10.1021/nl403620g

Abstract: The quantitative correlation of the catalytic activity with microscopic structure of heterogeneous catalysts is a major challenge for the field of catalysis science. It requests synergistic capabilities to tailor the structure with atomic scale precision and to control the catalytic reaction to proceed through well-defined pathways. Here we leverage on the controlled growth of MoS2 atomically thin films to demonstrate that the catalytic activity of MoS2 for the hydrogen evolution reaction decreases by a factor of ~4.47 for the addition of every one more layer. Similar layer dependence is also found in edge-riched MoS2 pyramid platelets. This layer-dependent electrocatalysis can be correlated to the hopping of electrons in the vertical direction of MoS2 layers over an interlayer potential barrier. Our experimental results suggest the potential barrier to be 0.119V, consistent with theoretical calculations. Different from the conventional wisdom, which thinks that the number of edge sites is important, our results suggest that increasing the hopping efficiency of electrons in the vertical direction is a key for the development of high-efficiency two-dimensional material catalysts.