2024.08.20

- Solving the high-temperature heat treatment problem of perovskite solar cells by modifying the electron transport layer... Uniform thin film formation and defect control are possible even in low-temperature processes, so it can be applied to various photovoltaic devices

- It can also be applied to flexible plastic substrates, so commercialization is expected... Published in the renowned international academic journal in the field of physics and applications

A Korean research team has developed a next-generation solar cell manufacturing technology that ensures high efficiency and stability even in low-temperature processes.

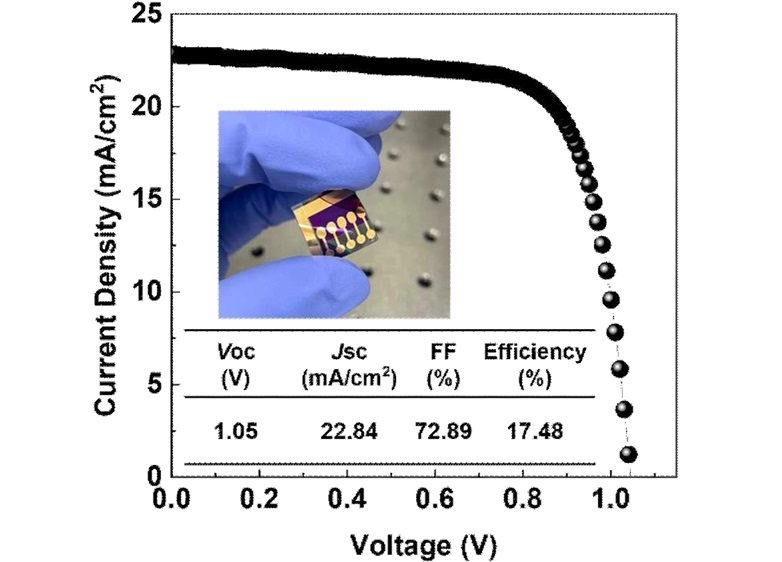

The Gwangju Institute of Science and Technology (GIST, President Kichul Lim) announced that the research team of Research Institute for Solar and Sustainable Energies’s Senior Researcher Hongkyu Kang, Research Professor Soo-Young Jang, Professor Kwanghee Lee developed a flexible perovskite solar cell manufacturing technology with a low-temperature process efficiency of 17.48% and significantly improved light stability (output decrease rate from 45% → 5% over 360 minutes). Tin oxide (SnO2), which is mainly used as a perovskite electron transport layer*, is generally heat-treated at high temperatures above 150 degrees Celsius, but this has adverse effects such as thermal shrinkage on polyethylene terephthalate (PET, a synthetic resin), which is mainly used as a flexible transparent electrode.

To solve the problem of high-temperature heat treatment, the research team introduced naphthalene diimide material and formed a uniform electron transport layer thin film even in a low-temperature process.

The flexible perovskite solar cell based on the modified electron transport layer showed an efficiency of 17.48%, which is the highest efficiency among perovskite solar cells produced by a low-temperature process among flexible transparent electrode films that do not contain indium tin oxide (ITO)* reported so far, the research team explained.

The high rarity of indium tin oxide is an obstacle to the commercialization of flexible perovskite solar cells, and the inherent brittleness of the material makes it prone to cracking due to repeated bending and thermal stress, so the development of a flexible transparent electrode that does not contain indium tin oxide is of great significance.

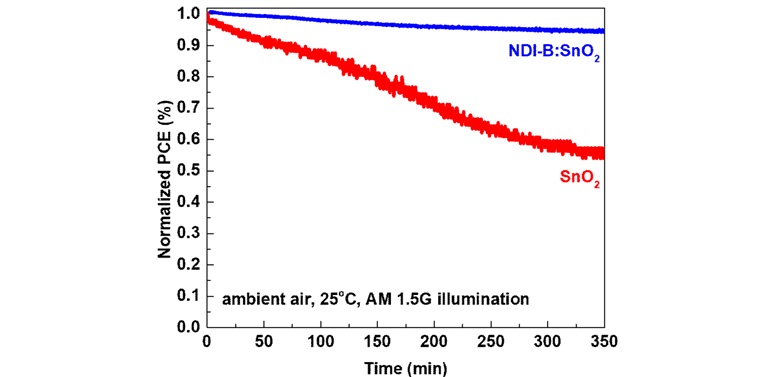

As a result, it was confirmed that the output measured based on the maximum output state decreased by 45% compared to the initial output for 360 minutes in an ambient air environment when conventional SnO2 was used, whereas it decreased by only 5% compared to the initial output when modified SnO2 was used, indicating a significant improvement in light stability*.

Comparison graph of solar cell stability under ambient air environment conditions of unmodified SnO2 and modified SnO2: The solar simulator shows the efficiency reduction rate compared to the initial efficiency at the maximum output state of each solar cell. In the case of unmodified SnO2, it decreased by about 45%, while in the case of SnO2 modified with naphthalene diimide material, it decreased by about 5%, confirming that the photostability was improved.

Light stability is an important indicator for determining the commercialization of solar cells, as it can be used to determine the lifespan of solar cells through the rate of decrease compared to the initial output when exposed to a solar environment using a solar simulator.

In particular, this study is significant in that it is the result of industry-academia cooperation in which GIST developed the original technology for the first time in Korea, transferred the technology to Once Co., Ltd., and Once Co., Ltd. granted exclusive licensing rights to MSWAY Co., Ltd. for successful mass production.

MSWAY Co., Ltd. has been granted exclusive rights to a technology that can replace indium-based transparent electrodes that were previously impossible to produce domestically and had to be entirely imported, which was transferred from GIST to ONCE Co., Ltd. MSWAY Co., Ltd. is the first in the industry to domestically produce and mass-produce flexible transparent electrode films and is supplying them to various domestic and foreign organizations.

Senior Researcher Hongkyu Kang said, "The significance lies in the fact that it not only solves the high-temperature process problem, which is a major obstacle to the development of flexible perovskite solar cells, but also develops an ITO-free flexible perovskite solar cell with high energy conversion efficiency through a low-temperature process. It is expected that the commercialization of perovskite based flexible solar cells can be accelerated in the future."

This study was conducted with the support of the Climate Change Response Technology Development Project, the Mid-career Researcher Project, and the Institutional Project of the Research Institute for Solar and Sustainable Energies of Gwangju Institute of Science and Technology supported by the Ministry of Science and ICT and the National Research Foundation of Korea, and was published online on July 15, 2024, in ‘Small,’ a paper ranked in the top 7.26% of JCR in the physics and applied fields.

* electron transport layer: A layer inserted in the middle to ensure that electrons excited in the active layer are transported to the electrode.

* indium tin oxide (ITO): A transparent electrode widely used in the electronics industry, including semiconductors, displays, and solar cells. The research team improved the efficiency of perovskite solar cells by reducing defects between the electron transport layer and the perovskite layer and

suppressing non-luminescent recombination* using modified tin oxide (SnO2).

* non-luminous recombination: This means that excited electrons and holes cannot move toward each electrode and recombine without emitting light due to defects within the device.