2016-02-02

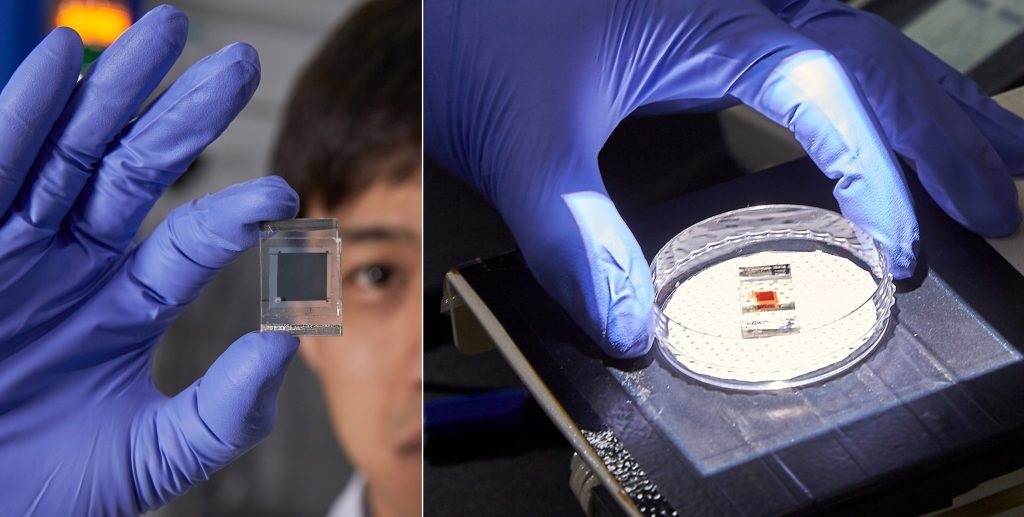

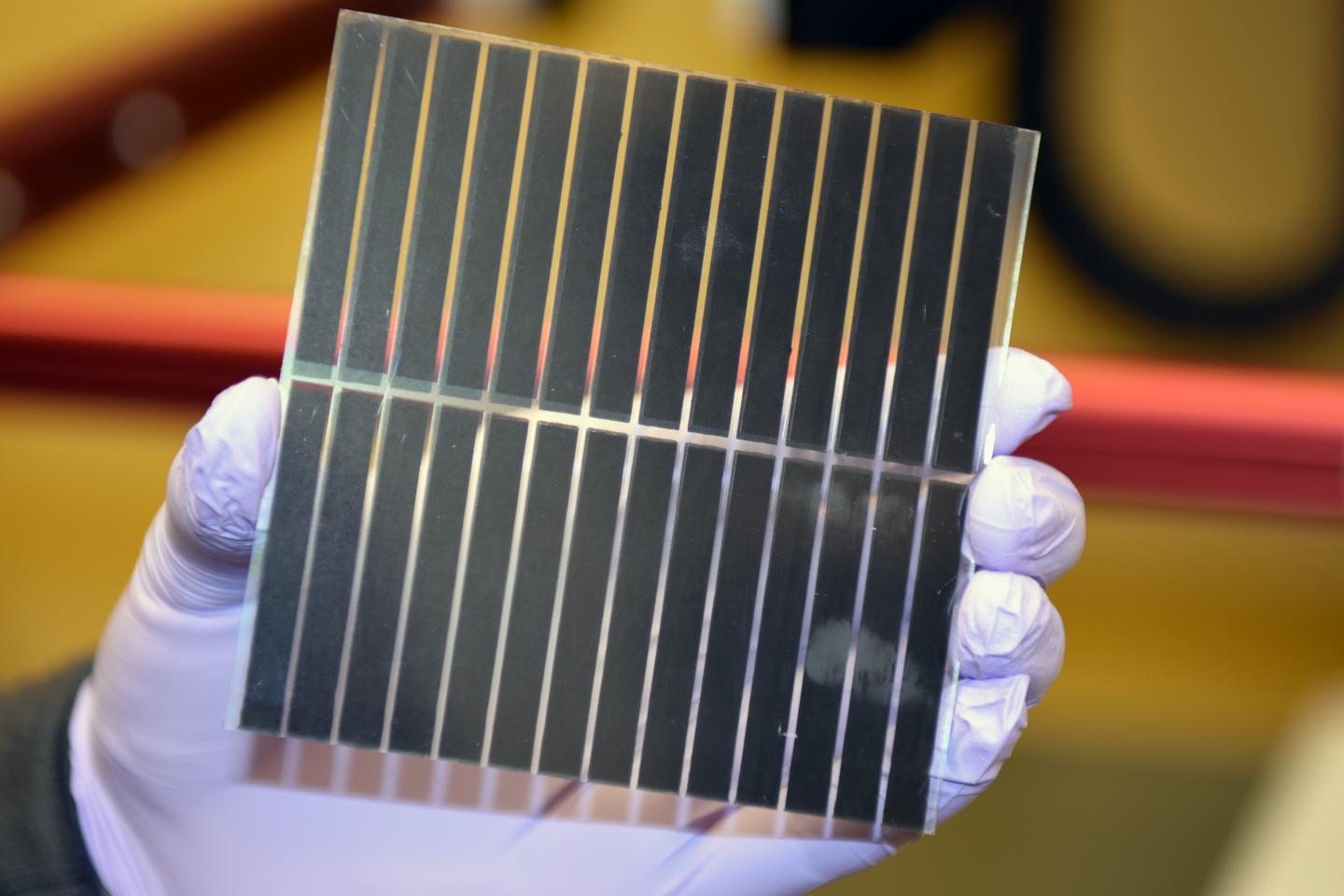

With support from the National Research Foundation of Korea (President Chung Min Keun), GIST Professor Kwanghee Lee who is also the Associate Director of the Heeger Center for Advanced Materials has successfully led a research team to develop a large-area organic solar cell module with a module efficiency of 7.5%, which is the highest efficiency achieved in the world for organic solar cell modules, by using a consecutive printing process. The consecutive printing process utilizes a slot-die coating machine for the patterned coating process and a doctor-blade coating machine for depositing the solution-processed layer onto the photoactive layer.

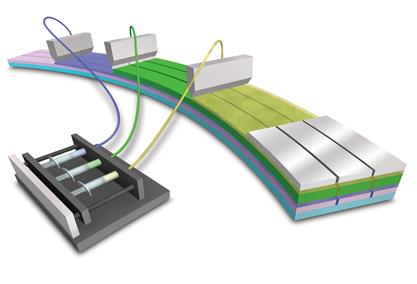

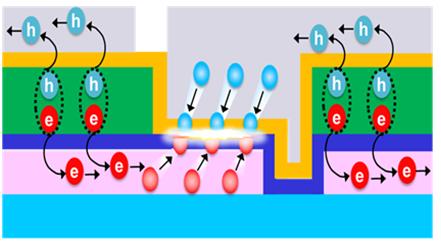

Conceptual module structure consisting of patternless electron-transport and hole-transport layers and one patterned photoactive layer.

This innovative module architecture developed by Professor Lee's team significantly increases organic solar cell efficiency because it can simultaneously reduce both patterning process and aperture loss. An inherent weakness of current solar cell module architecture processes is aperture loss, which is a major contributor to drastically degrading the performance of large-area organic solar cell modules. The problems associated with aperture loss has been the most difficult obstacle in preventing the commercial fabrication of organic photovoltaic modules via printing techniques.

Working mechanisms for the module: Photogenerated electrons and holes from each sub-cell transport along the counter electrodes and are injected into the charge transport layers of the series connection region, and recombine together at the interface between the charge transport layers.

Professor Lee's research team has overcome the issues caused by aperture and patterning process loss by creating a series connection method that facilitates module fabrication by using a charge recombination feature that occurs at contacts between electron- and hole-transport layers without having to pattern the charge transport layer. This monolithic interconnection approach has resulted in the creation of a new module architecture for efficiently manufacturing large-area printed organic solar cell modules without the aid of additional and complicated post-patterning processing.

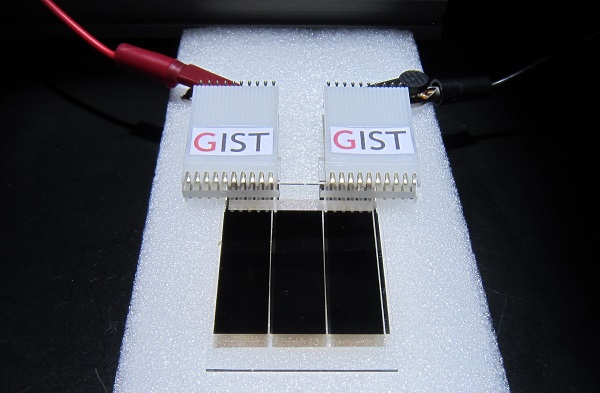

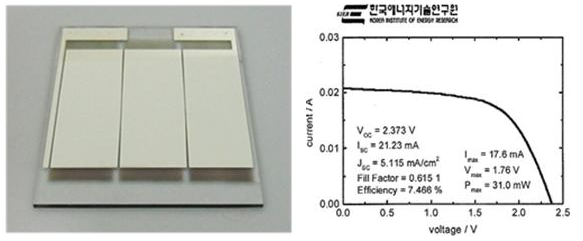

A photograph image of our module (size of 60 x 44.5 mm) along with the Korea Institute of Energy Research-certified J–V characteristics of our organic solar cell module.

The results of the research was published on January 5, 2016, in Nature Communications in a paper entitled "A series connection architecture for large-area organic photovoltaic modules with a 7.5% module efficiency" and authored by: Soonil Hong, Hongkyu Kang, Geunjin Kim, Seongyu Lee1, Seok Kim, Jong-Hoon Lee, Jinho Lee, Minjin Yi, Junghwan Kim, Hyungcheol Back, Jae-Ryoung Kim, and Kwanghee Lee.

The commercial implications of this research is far-reaching as flexible solar cell modules will be an excellent candidate as a renewable power source for the ever-increasing market of portable electronic devices as well as portable/wearable electronic devices.