August 25, 2016

Solar energy can be stored by converting it into hydrogen. But current methods are too expensive and don’t last long. Using commercially available solar cells and none of the usual rare metals, researchers at EPFL and CSEM have now designed a device that outperforms in stability, efficiency and cost.

How can we store solar energy for period when the sun doesn’t shine? One solution is to convert it into hydrogen through water electrolysis. The idea is to use the electrical current produced by a solar panel to ‘split’ water molecules into hydrogen and oxygen. Clean hydrogen can then be stored away for future use to produce electricity on demand, or even as a fuel.

But this is where things get complicated. Even though different hydrogen-production technologies have given us promising results in the lab, they are still too unstable or expensive and need to be further developed to use on a commercial and large scale.

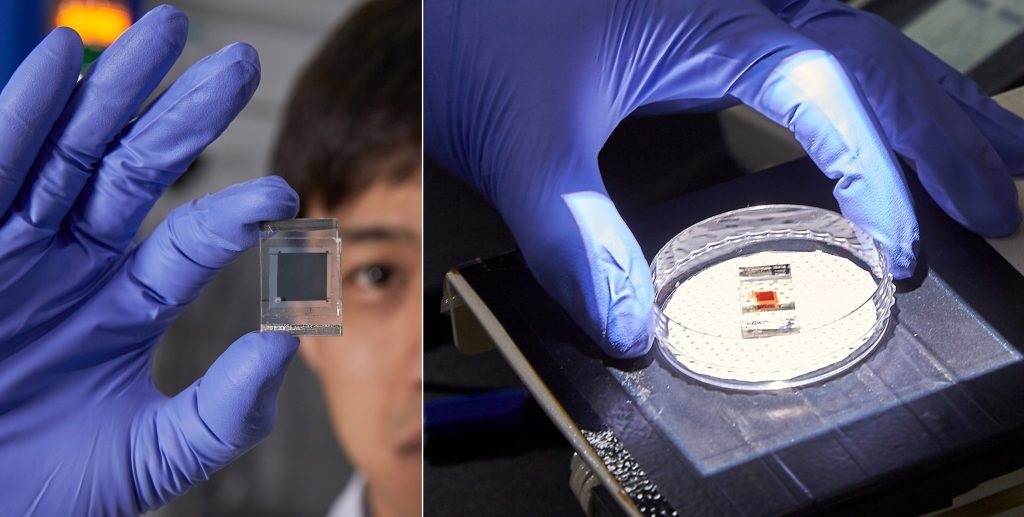

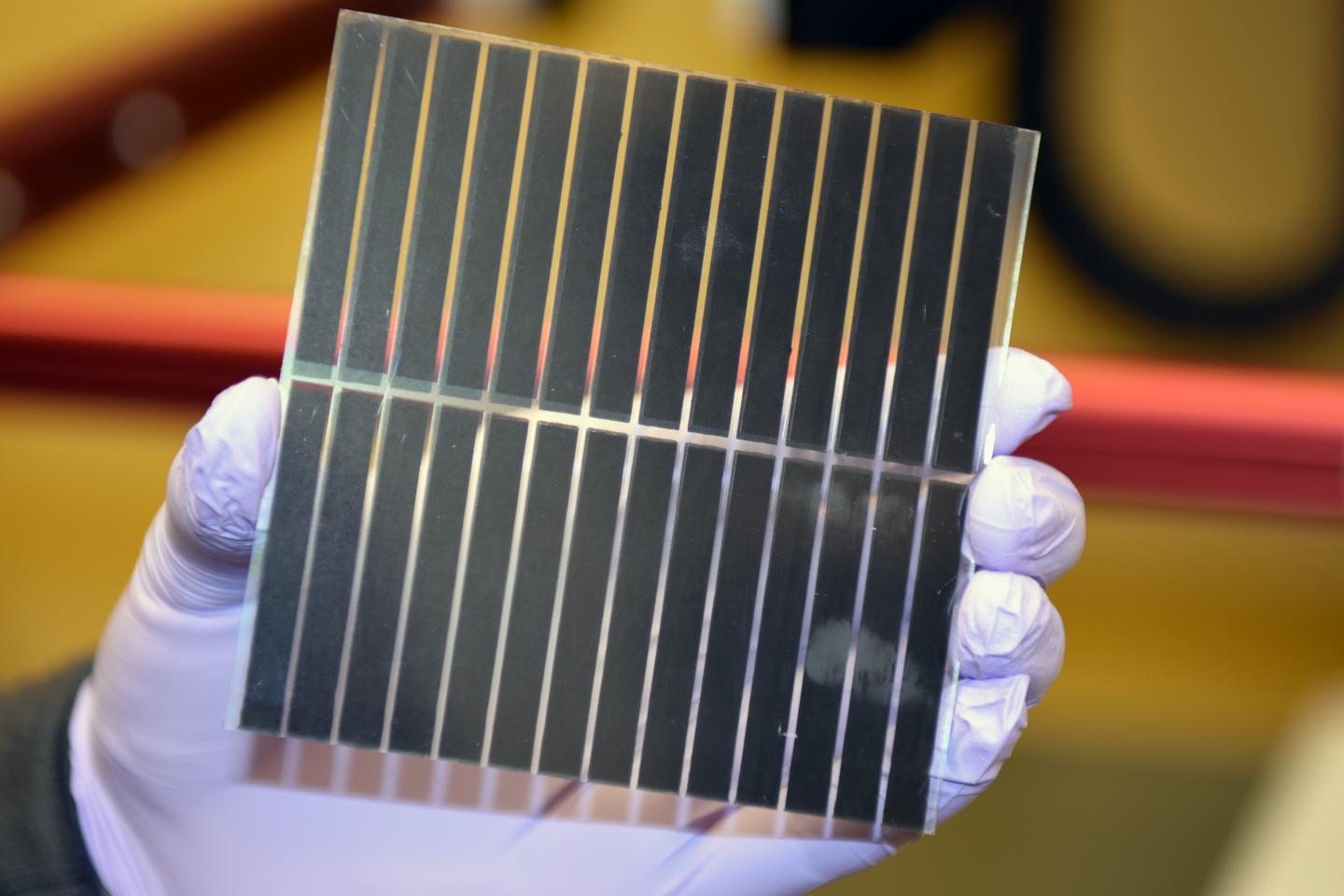

The approach taken by EPFL and CSEM researchers is to combine components that have already proven effective in industry in order to develop a robust and effective system. Their prototype is made up of three interconnected, new-generation, crystalline silicon solar cells attached to an electrolysis system that does not rely on rare metals. The device is able to convert solar energy into hydrogen at a rate of 14.2%, and has already been run for more than 100 hours straight under test conditions. In terms of performance, this is a world record for silicon solar cells and for hydrogen production without using rare metals. It also offers a high level of stability.

Enough to power a fuel cell car over 10,000km every year

The method, which surpasses previous efforts in terms of stability, performance, lifespan and cost efficiency, is published in the Journal of The Electrochemical Society. “A 12-14 m2 system installed in Switzerland would allow the generation and storage of enough hydrogen to power a fuel cell car over 10,000 km every year”, says EPFL researcher Christophe Ballif, who co-authored the paper and who also heads the CSEM PV-center.

High voltage cells have an edge

The key here is making the most of existing components, and using a ‘hybrid’ type of crystalline-silicon solar cell based on heterojunction technology. The researchers’ sandwich structure – using layers of crystalline silicon and amorphous silicon – allows for higher voltages. And this means that just three of these cells, interconnected, can already generate an almost ideal voltage for electrolysis to occur. The electrochemical part of the process requires a catalyst made from nickel, which is widely available.

Related Journal Article