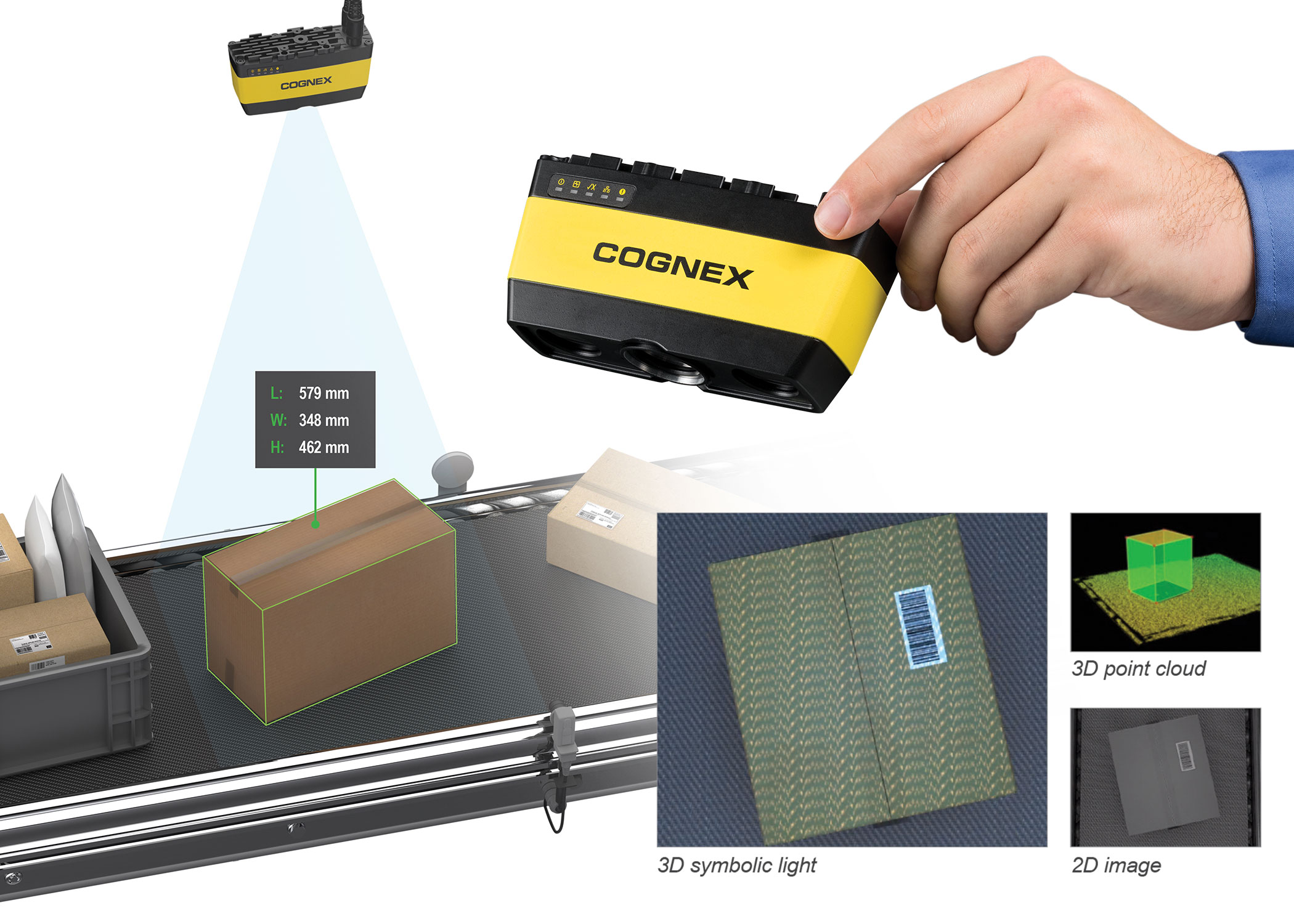

Natick, MA, USA August 16, 2019 - Cognex Corporation (NASDAQ: CGNX), the leader in machine vision and industrial barcode reading, today unveiled the 3D-A1000 Dimensioning System. Featuring breakthrough smart camera technology, the 3D-A1000 solves even the toughest static and in-motion dimensioning challenges to optimize logistics, packaging, and warehousing operations.

With patented 3D symbolic light and point cloud technology, the 3D-A1000 makes it possible to quickly and accurately inspect a broad range of fast moving and complex packages. Unlike competitive technology, the 3D-A1000 handles high-speed motion, uneven transitions, curved conveyance, and colorful target surfaces. Additionally, it outputs precise data and accurate measurements and detects overpacked or out-of-gauge items.

“Online consumer buying trends are driving new automation improvements in today’s logistics processes. Facilities are looking to machine vision to meet complex quality, throughput, and traceability demands,” said Carl Gerst, Cognex Senior Vice President. “The 3D-A1000 Dimensioning System provides the performance and flexibility necessary to improve operational efficiencies, with simple integration.”

The 3D-A1000 is factory calibrated and ready for system integration immediately. Unlike conventional systems that can take a skilled engineer three to six hours to install and calibrate, the 3D-A1000 is easily installed in less than 15 minutes using an intuitive setup wizard.

For more information, visit cognex.com/dimensioning