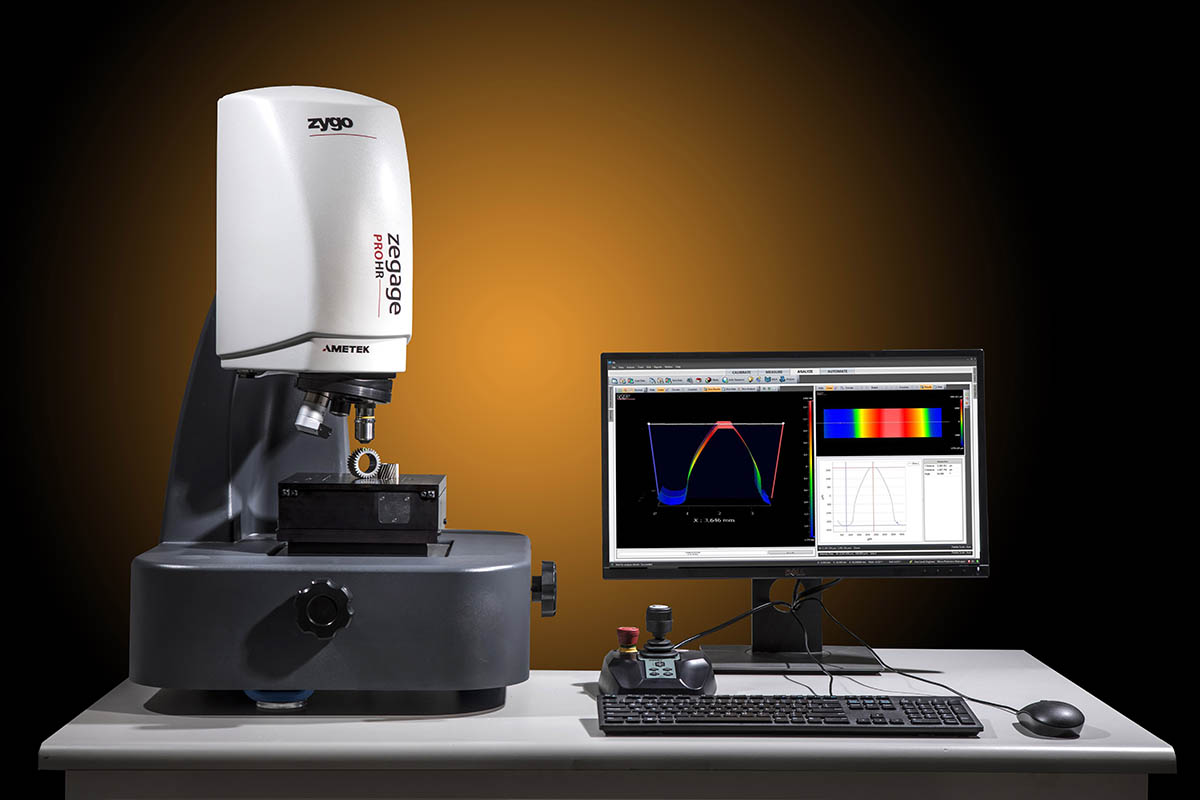

Middlefield, CT, October 17, 2018 – Zygo Corporation has announced the introduction of its latest generation of ZeGage™ 3D optical profiling instruments providing precise and rapid non-contact measurement of surface topography for enhanced quality and process control.

The two new models, ZeGage Pro and ZeGage Pro HR, offer up to 2X improvement in data points, a 50% larger maximum field of view, and increased measurement speed with simplified setup. The ZeGage Pro systems maintain a small footprint, with versatile performance and ease of use. The new system’s time-saving large field-of-view, combined with optional automated part staging, allows larger components to be measured quickly and easily in most environments.

At the core of the ZeGage Pro 3D optical profiler is ZYGO’s Mx™ software platform. This comprehensive user-friendly control and analysis platform supports a broad range of surface metrology applications and data analyses. The rich suite of features includes results compliant with ISO 25178 and 4287, image stitching, and automated measurement patterns. The ZeGage Pro profilers now expand this offering with unique features that simplify operation and minimize operator variability, such as ZYGO’s exclusive fast focus, Part Finder and Smart Setup tools.

Commenting on the launch of the ZeGage Pro and ZeGage Pro HR profilers, Eric Felkel, Product Manager of Optical Profilers at ZYGO said, “Our latest generation of ZeGage profilers represents a new class of non-contact surface measurement system, while complementing our existing portfolio of metrology products. It integrates our industry-leading and differentiated Coherence Scanning Interferometry (CSI) technology into a compact system, delivering fast and flexible results to meet the most stringent QC/QA requirements.

“The ZeGage Pro sets a new benchmark for high value, easy-to-use, non-contact metrology tools that deliver precision on the production floor, without the need for expensive vibration isolation systems or consumables,” he added.

Summary of Main Features:

- Large format imaging sensor yields 1.9 million data points - a 50% increase in field of view and 2X more data points compared to the previous generation

- SureScan™ technology reduces vibration sensitivity, providing greater flexibility in locating the instrument within a facility

- Improved data acquisition and speed; >1.5X faster than the previous generation

- Higher sensitivity and dynamic range for reliable and precise metrology on challenging surfaces (e.g. high slopes, low reflectivity, rough texture)

- Innovative and intuitive Mx™ software with "smart" features for enhanced ease-of-use, automation and productivity

Built on Zygo Corporation’s more than forty years of 3D optical inspection and metrology expertise, the ZeGage Pro and ZeGage Pro HR systems are precision-manufactured at ZYGO’s US-based global headquarters.

To learn more about the latest ZeGage-series of 3D Optical Profilers, visit www.zygo.com