26 Apr 16

by Karoline Lawætz

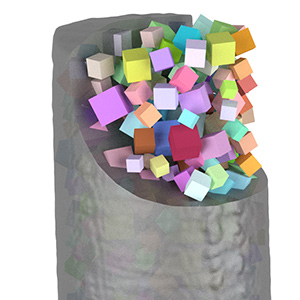

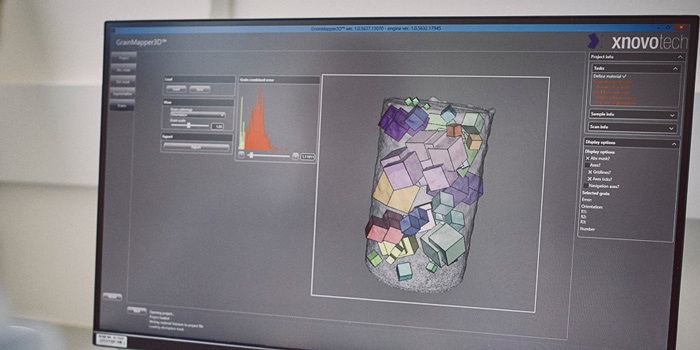

Now you can easily and quickly generate 3D images of, e.g., metal and identify any weaknesses—without destroying the material. The spin-out company Xnovo Technology uses advanced X-ray technology for looking into compact materials.

“It is always a good day when I have visited a customer and can see that our product makes a difference there,” says a somewhat jet-lagged Erik Lauridsen, CEO of Xnovo Technology, fresh home from a visit to U.S. Naval Research Laboratory, USA—the very first buyer of Xnovo’s GrainMapper3D™ which can analyse compact material such as metal and concrete, so you get a three-dimensional image of the structure.

Xnovo’s technology generates a 3D image of the grain structure within a material sample without the material sample being destroyed.

Illustration: Xnovo

It is not more than six years ago that Erik Lauridsen and his colleague from the former Risø DTU (now DTU Physics), Henning Friis Poulsen, were on a plane from Tokyo to Copenhagen. They had plenty of time to talk and when they landed in Denmark, they had hatched the idea for the technology which forms the basis of Xnovo—a small company in rapid development.

“With our current speed, we do not need more investors right now. We have had income from day one, so things are going quite well,” says Erik Lauridsen.

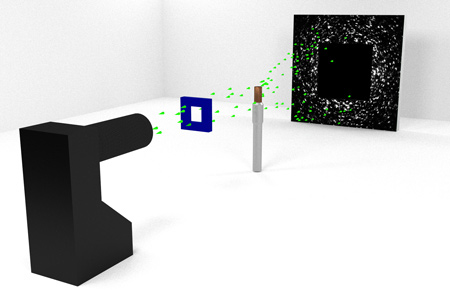

Xnovo’s solution is mounted on sophisticated X-ray equipment from the major manufacturer of microscopes Carl Zeiss. On this equipment, you can study metal, concrete, and minerals, for example, and achieve a deeper understanding of how a material works under different impacts.

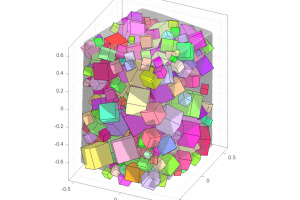

Illustration: Xnovo

From mega facility to laboratory model

The two researchers had been on one of their many work-related trips. As specialists in the use of a state-of-the-art technology for facilities with extreme space requirements—the so-called synchrotrons—they had had to tour the world and assist their colleagues with using the equipment on site.

A synchrotron is a large particle accelerator which is almost a kilometre in circumference. There are only a limited number of them in Europe and they are in high demand. Therefore, the Max IV synchrotron is now being built in Lund. It will be one of the world's leading facilities.

The synchrotron can be used for generating powerful X-ray radiation for, e.g., protein crystallography. The radiation is the result of charged particles (electrons) being circulated so they are deflected.

“To get access to conduct experiments with a synchrotron is often a long and costly affair primarily reserved for university researchers. First you must go through a long application process, and then follows typically a long period with complicated data analysis before you can use your findings. To ensure wider and easier access to our technology—especially for industry—we started developing the idea of an alternative solution that can make similar analyses on ordinary X-ray sources in the laboratories,” says Erik Lauridsen.

And the goal has been reached: Xnovo’s unit is mounted on an X-ray microscope from the major manufacturer of microscopes Carl Zeiss. The physical footprint of the unit is not more than 2 x 1 meters, and the analysis can be carried out in less than one day. The purpose of the developed solution is not to make superfluous the powerful synchrotron facilities in Europe, such as Max IV, but to offer a supplementary laboratory solution and thereby ensure increased access to this technology. The partnership with Carl Zeiss has been crucial and something that the two entrepreneurs established very early in the process.

Yes we can!

The idea was presented to business developers at DTU, who immediately sent Erik Lauridsen to California on a course for entrepreneurs. “It was an intensive week, where we practised pitching our idea during the day and speed-dated potential investors in the evening. It was incredibly effective,” says Erik Lauridsen. And why not seize the opportunity and arrange a meeting with one of the world leaders within X-ray microscopy, Xradia, who just happened to be domiciled in San Francisco? Erik Lauridsen did just that. Xradia was immediately hooked on the project and promised to cover the costs of developing version 1.0 , in return for the sales rights to the product.

“I returned home from California with the belief that of course it could be done,” says Erik Lauridsen.

And it could it. The partnership is still running smoothly, even after Xradia has been acquired by Carl Zeiss, which is much larger and has a broader customer base. Not bad for the marketing of Xnovo’s technology.

With Xnovo’s X-ray unit, you can conduct a brand new type of measurements previously reserved for users of large-scale facilities, such as the huge synchrotron facility Max IV in Lund, Sweden.

Illustration: Xnovo

With Xnovo’s software, so-called diffraction signals from material samples can be analysed and translated into a 3D picture of the material’s crystal structure. In this way, both universities and industrial companies have access to immediate solutions in the field of advanced materials characterization.

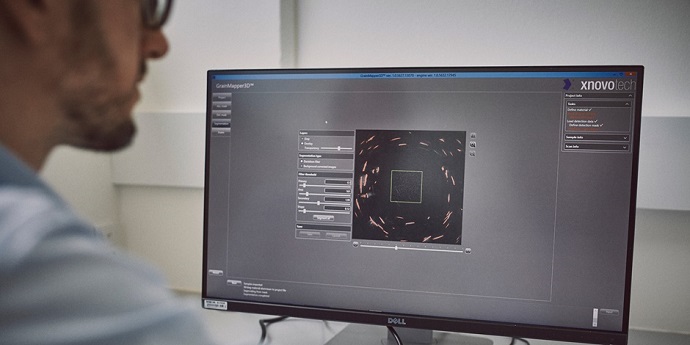

Photo: Xnovo

On the shoulders of pioneers

“Our company builds on a strong tradition of Risø within materials characterization, going all the way back to the beginning of the 1990s. Back then, they invented methods for forming 2D images of crystalline materials. One of the researchers involved at the time was Niels-Henrik Schmidt who later made a successful business out of it. His company has always been a source of inspiration for us, so I think that you could say that we have followed in Niels-Henrik Schmidt’s footsteps—this time just in 3D,” says Erik Lauridsen.

Niels-Henrik Schmidt established the company HKL Technology A/S, and when he sold it in 2007, he controlled approximately half of the world market.

But business acumen is one thing. Another possessing the drive to take research findings out of the laboratory, so that others may benefit from them.

“In my 15 years as a researcher at Risø (now DTU Energy, ed.), I was always focused on a wide application of my research results, so I have always had a close cooperation with industry,” says Erik Lauridsen.

It was also completely in line with the recommendation of DTU Energy which gave its full support to Erik Lauridsen in pursuing his entrepreneur ambitions. Both benefitted Xnovo.

Network absolutely crucial

A company such as Xnovo needs a large network in research-oriented industries, and here, Erik Lauridsen a solid basis on which to build.

“We’re still doing research, only now with a commercial angle. It’s my job to ensure that we are not only doing research for fun—the results must be commercializable. Some of our work is the further development of existing ideas, but we also develop new ones,” Erik Lauridsen assures.

And here, the universities are important sounding boards as this is typically where new ideas and trends emerge.

The combination of state-of-the-art X-ray equipment from Carl Zeiss and specially developed software from Xnovo enables analyses of material such as metal and concrete down to the smallest particle size. The result is displayed in 3D.

New technology

For many years, researchers have had access to electron microscopy which can analyse surfaces of materials. If you grind the material down layer by layer, you get a 3D image of the structure.

This technology thus destroys the sample, and it is therefore impossible to follow the same material sample over time and study the development.

However, GrainMapper3D™ does not destroy the sample material during the analysis.

Here, you study more than just cracks, for example. You also look at the grain structure with which the cracks interact, which gives you an impression of why they occur. You thus get a basic understanding of the mechanics that affect the material.

The microscope can look at everything crystalline. In addition metal and concrete, it is also used for, e.g., minerals and semiconductor materials.

Small physical footprint

Prior to the development of Xnovo’s GrainMapper3D ™, the only possibility of conducting the kinds of studies was to use synchrotrons. They are huge particle accelerators of almost a kilometre in circumference.

Xnovo’s GrainMapper3D™ takes up just 2 x 1 metres and can be installed in an ordinary laboratory.

Results the same day

It may take up to a year to get access to a synchrotron. Analyses on Xnovo’s GrainMapper3D ™ can be performed in a single day.