TOKYO, July 16, 2015—Canon Inc. and Canon Marketing Japan Inc. today announced the launch in Japan of the new RV300 and RV500 3-D Machine Vision Systems, which enable the three-dimensional recognition of small-scale parts randomly assembled in a pile. Amid increasing demand for automated processes in production lines, Canon is strengthening its presence in the 3-D machine vision market with an expanded lineup that comprises the new RV300 and RV500, which join the RV1100 (launched in April 2014), enabling the Company to respond to a wide range of parts-provision needs for production lines across a variety of industries.

Enables the 3-D recognition of small parts

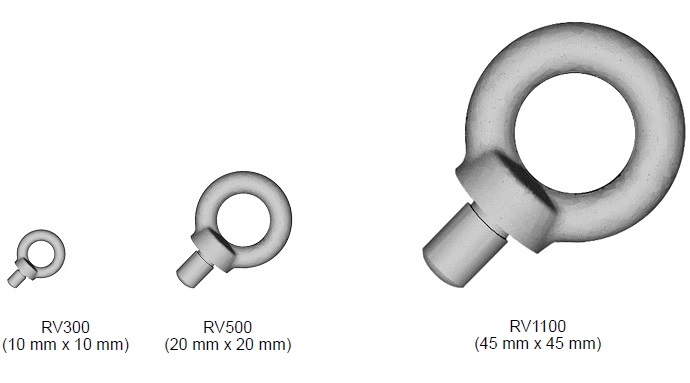

The new RV300 and RV500 enable the three-dimensional recognition of randomly piled parts as small as approximately 10 mm square and approximately 20 mm square, respectively, sizes that are smaller in scale than the parts that can be handled by the RV1100, which can recognize parts down to approximately 45 mm square.* By facilitating the recognition of smaller parts, the two new systems can be employed in a wide range of industries across various production lines that must deal with small parts, such as the automotive and automotive components industries, as well as the electronics industry.

Enhanced recognition speed

Contributing to improved production-line efficiency, both the RV300 and RV500 deliver high-speed performance, taking only approximately 1.8 seconds to recognize randomly collected small-scale parts in 3-D and send this data to a robotic controller unit.

High-precision three-dimensional recognition

Realizing a high level of accuracy, the new RV300 and RV500 achieved exceedingly small error tolerances of less than 0.1 mm and 0.15 mm, respectively, over repeated tests when gathering and calculating data under the same conditions regarding the shape and orientation of parts randomly assembled in a pile.

The Canon RV300 and RV500 3-D Machine Vision Systems will go on sale in Japan on July 16, 2015.

* As a condition when measuring, the RV300, RV500 and RV1100 require minimum pattern areas projected from the machine vision head of 100 mm2, 400 mm2 and 2,025 mm2.

1. Enables the 3-D recognition of small parts

- The RV300 and RV500 enable the three-dimensional recognition of randomly piled parts as small as approximately 10 mm square and approximately 20 mm square, respectively, sizes that are smaller in scale than the parts that can be handled by the RV1100, which can recognize parts down to approximately 45 mm square.

- By facilitating the recognition of smaller parts, the two new systems can be employed in a wide range of industries across various production lines handling small-scale parts, such as the automotive and automotive components industries, as well as the electronics market.

- When combined with a robotic system, the RV300 and RV500 contribute to improved productivity by accelerating the automation of parts provision.

Comparison of sizes for smallest parts supported

2. Enhanced recognition speed

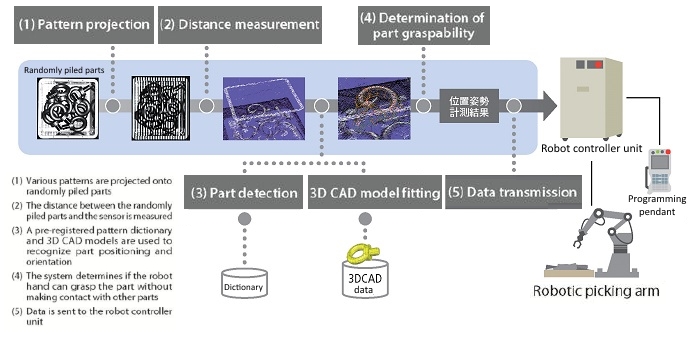

- Delivering high-speed performance, the RV300 and RV500 both take only approximately 1.8 seconds to recognize randomly gathered parts in three dimensions and send this data to a robotic controller unit. The two new 3-D machine vision systems, which can be integrated into production lines across a variety of industries that handle small parts, help to facilitate the automation of parts provision systems.

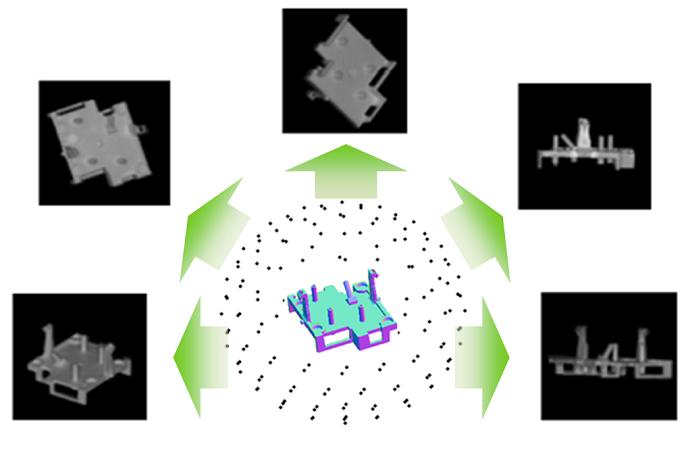

3-D Machine Vision System workflow

3. High-precision three-dimensional recognition

- Delivering a high level of accuracy, the new RV300 and RV500 achieved exceedingly small error tolerances of less than 0.1 mm and 0.15 mm, respectively, over the course of repeated tests when gathering and calculating data under the same conditions regarding the shape and orientation of randomly assembled parts.

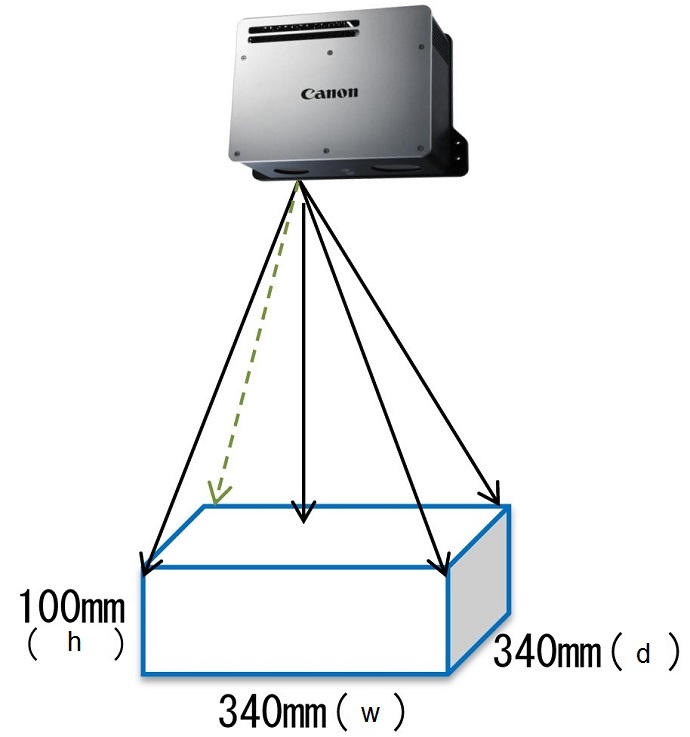

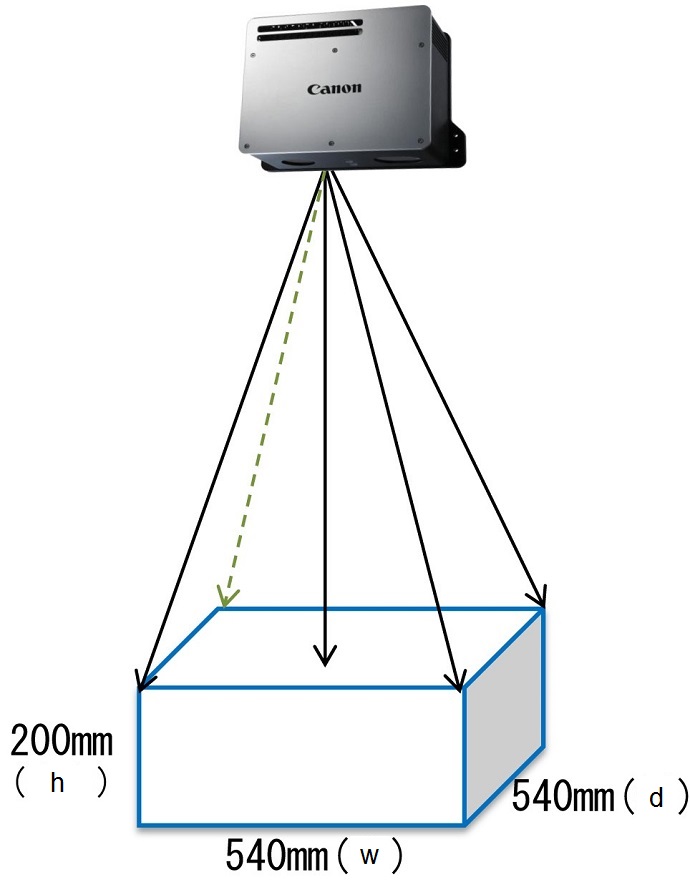

- The RV300 realizes a maximum measurement area of 340 mm (d) x 340 mm (w) x 100 mm (h), while the RV500 offers a measurement area of up to 540 mm (d) x 540 mm (w) x 200 mm (h). The two 3-D machine vision systems are capable of the high-precision recognition of small parts assorted in a random pile.

RV300 and RV500 measurement area comparison

RV300 and RV500 measurement area comparison

4. Easy setup for recognition of parts with complex shapes using CAD data (RV300, RV500 and RV1100 shared features)

- Users can easily register data for parts to be picked up by inputting CAD data and by capturing images of the parts randomly assembled in a pile.

- The 3-D machine vision system lineup’s detection system uses computer-generated images to automatically learn how to visually identify the parts, made possible by simply capturing images of parts in five different randomly assembled configurations, enabling users to register data in a short amount of time.

- Using a new approach that matches CAD data with not only distance measurement data but also gray-scale images, the RV300, RV500 and RV1100 are able to recognize a wide range of parts, including components with curved surfaces, components with few distinguishing features, and those with complex shapes.

- Users can easily register new parts or modify existing parts without the need for complex programming.

Learning how to visually identify parts using computer-generated graphics (illustration)

5. Easy system settings and management (RV300, RV500 and RV1100 shared features)

- By instantly measuring in three dimensions the placement and orientation of parts to be picked up by a robotic arm, Canon’s 3-D machine vision systems do away with the need for such equipment as two-dimensional sensors, which are conventionally used to recognize the positioning of parts, as well as work tables for the temporary placement of parts and feeder lines.

- The RV300, RV500 and RV1100 each include a 3-D machine vision head that incorporates both the pattern projector and imaging sensor in a single unit, enabling installation without the need for optical adjustments.

- The systems feature dust- and water-resistant body designs, making them easy to maintain once installed.

Machine vision market overview

In 2014, global sales of 2-D and 3-D machine vision systems for use with industrial robots totaled approximately 2.75 billion yen. Within this segment, sales of 3-D machine vision systems have been rapidly expanding. The market for 3-D machine vision systems is expected to grow significantly in the future, driven by strong demand for the further automation of production lines used by manufacturers in a variety of industries, including automotive and automotive component manufacturers. In response to these market trends, Canon will launch products offering high-speed, high-precision three-dimensional recognition capabilities. (Based on Canon research.)