July 26, 2024

Wilson Yang, PhD

The relentless pursuit of miniaturization, performance enhancement, and defect reduction in the semiconductor industry demands ever-more sophisticated inspection techniques. The Spectrolight Tunable Laser System (TLS), with its groundbreaking capabilities, emerges as a game changer in this domain, empowering manufacturers to achieve unprecedented levels of excellence. This white paper explores the transformative impact of the TLS on semiconductor inspection, specifically highlighting its unique wavelength and bandwidth control capabilities.

The Spectrolight TLS: Unparalleled Precision and Control

Spectrolight TLS is the only laser system providing continuous, precise control of wavelength and bandwidth. The wavelength range ranges from 410nm in the Visible to 1700nm in the SWIR in 1 nm increments. This unparalleled control capability allows the detection of even the smallest defects on semiconductor wafers. By precisely tuning the wavelength and bandwidth to match the specific absorption characteristics of the defect, TLS enables highly sensitive and accurate inspection. This feature is very important to identify and characterize. It ensures the production of high-quality semiconductor devices by removing defects such as scratches, particles, and contamination.

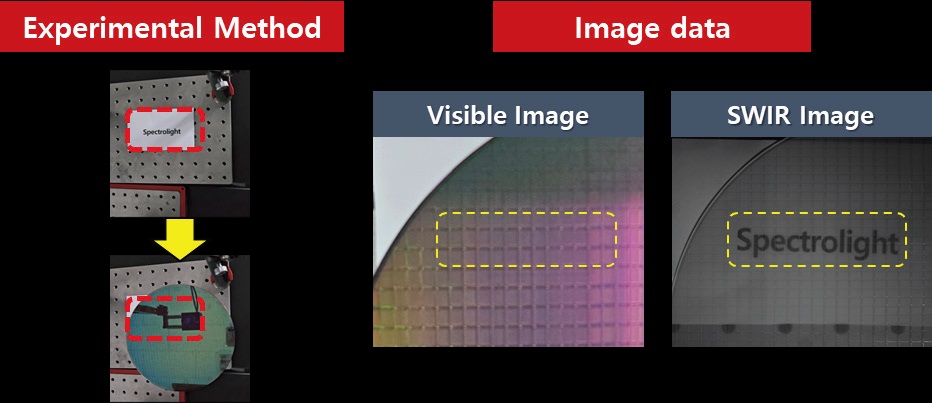

This image demonstrates the remarkable transmission property of the Spectrolight TLS. A silicon wafer placed on the light path allows the SWIR wavelength light to penetrate through it, revealing the printed text underneath. This capability opens doors to a wide range of inspection possibilities, transcending the limitations of traditional methods.

Beyond Defect Detection: Comprehensive Wafer Inspection

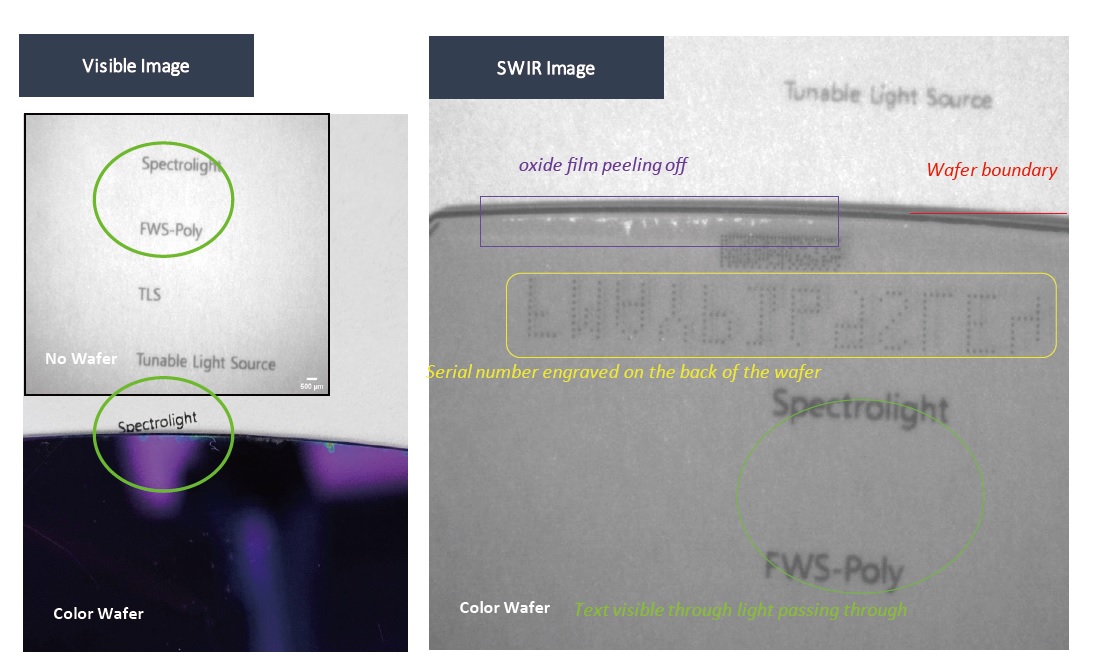

▶ Wafer Serial Number Identification: Using TLS, the wafer serial number can be identified even through the oxide layer. This feature enables efficient wafer tracking and management, streamlining the production process and improving traceability.

▶ Oxide Film Peeling Detection: TLS ensures the integrity and functionality of semiconductor devices by detecting even the smallest traces of peeling oxide film on the surface of a silicon wafer. This feature prevents potential device failures and ensures consistent product quality.

Figure 2. Serial number, oxide stripping, and text visible through light passing using Spectrolight TLS

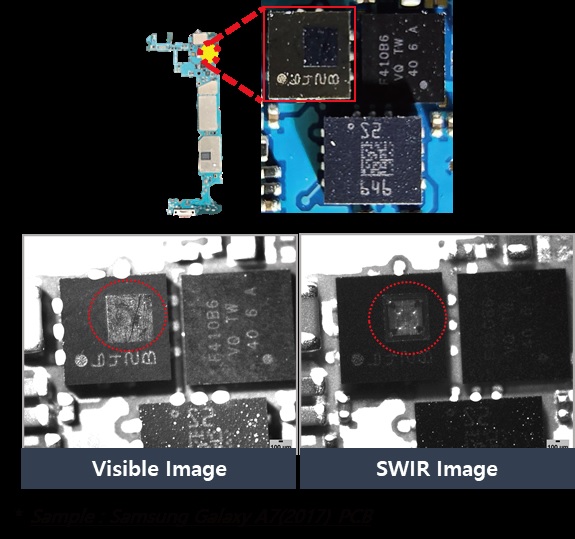

Internal Inspection Capabilities: Unveiling Silicone-Encapsulated Components

The capabilities of Spectrolight TLS extend beyond surface inspection. The transparent nature of the SWIR range allows the ability to penetrate silicon to inspect internal components encapsulated within the silicon. This opens up new levels of inspection possibilities in a variety of industries.

Include:

Sample: Samsung Galaxy A7 (2017) PCB

▶ Semiconductor Packaging: Inspecting internal wire bonds and connections within silicone-encapsulated packages.

▶ Automotive Electronics: Examining internal components of sensors, actuators, and other electronic modules protected by silicone.

Conclusion: A Catalyst for Semiconductor Innovation

Spectrolight’s Tunable Laser System (TLS) is changing the game for semiconductor inspection, helping manufacturers achieve unprecedented levels of precision and efficiency. Combining unique wavelength and bandwidth control creates a light source that could help shape the future of this rapidly evolving technology. Rather than making different choices every time due to increasingly smaller semiconductors and changes in materials, why not test at the right wavelength? As a catalyst for semiconductor innovation, TLS paves the way for a new era of excellence in this important industry.

Simple Introduction

TLS-RED can generate wide wavelength ranges of approximately 410 nm to 1700 nm and can control the FWHM 2 to 15 nm (nominal), and TLS-BLUE has the same wide wavelength ranges with fixed FWHM at 10 or 20 nm. TLS-RED is suitable for fields that require precise scanning, and TLS-BLUE is ideal for fields that require high output. By using Spectrolight’s TLS, users can freely select the output power and wavelength ranges according to their needs.

TLS is a picosecond tunable laser that can be applied to various fields, from fluorescence microscopy to time-resolved spectroscopy, such as TCSPC, Hyperspectral imaging, Machine vision, Semiconductors, Sensors, and other applications.

TLS-RED (Tunable bandwidth). TLS-BLUE (Fixed bandwidth)