September 12 2022

Researchers from The University of Queensland have developed a tool to measure the properties of lasers – to potentially benefit a range of industries from telecommunications to security and car manufacturing.

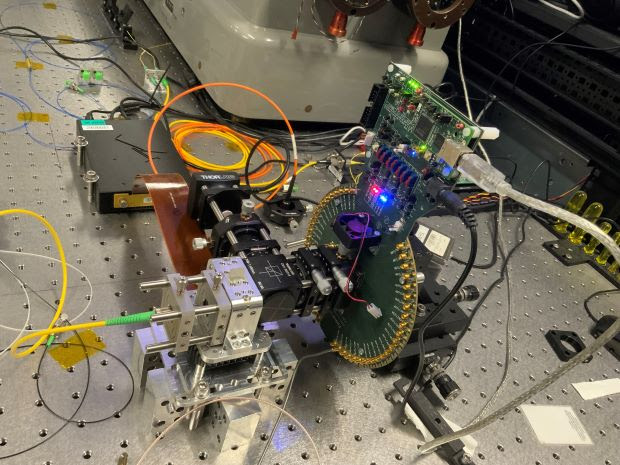

Dr Martin Plöschner from UQ’s School of Information Technology and Electrical Engineering (ITEE) and his team spent three years working on a way to make lasers faster and improve their performance.

“The tool we developed measures the output of vertical-cavity surface-emitting lasers (VCSELs) and allows the examination of the large amounts of data their light carries,” Dr Ploschner said.

One key area where lasers are used is optical data communication – where laser light zips through optical fibres to deliver information.

But the ever-increasing demand for faster and more frequent access to data is pushing optical fibre networks around the world to their limit - the so-called ‘capacity crunch’.

Study co-author Dr Joel Carpenter said the laser light pulses relayed along the glass or plastic fibres travel at different speeds and can overlap, slowing down the process.

“Imagine yelling to a friend through a long concrete pipe,” Dr Carpenter said.

“Your message will distort depending on how much the pipe echoes, and you’ll also have to wait for the echoes to die down from one message before you can send the next.

“It’s a similar problem in large groups of computer servers, with the amount of echo dependent on the shape and colour of the lasers being launched into the optical fibre.”

Measuring the properties of lasers is vital to making improvements, but until now there has been no method to fully capture this complexity.

The researchers said the tool will make it possible to identify the beam features that contribute to ‘pulse spreading’ in the optical link, which slows down data.

“Laser engineers can then design lasers without these rogue features, leading to optical links with higher speed and longer distance of operation,” Dr Ploschner said.

“And any tool that can facilitate faster data transfer over longer distances is helpful.”

Dr Plöschner said improved laser technology is set to benefit a range of industries, from telecommunications to security and car manufacturing.

“Autonomous cars use lasers to make a 3D image of the scene to help them navigate through traffic or reverse park in a tight spot,” he said.

“And you’re scanned by hundreds of tiny lasers every time you use facial recognition to unlock your smartphone.

“It comes as no surprise then that there’s a huge demand to make lasers with improved performance.”

The UQ team partnered with leading laser manufacturer II-VI Inc.

The research has been published in Nature Communications.