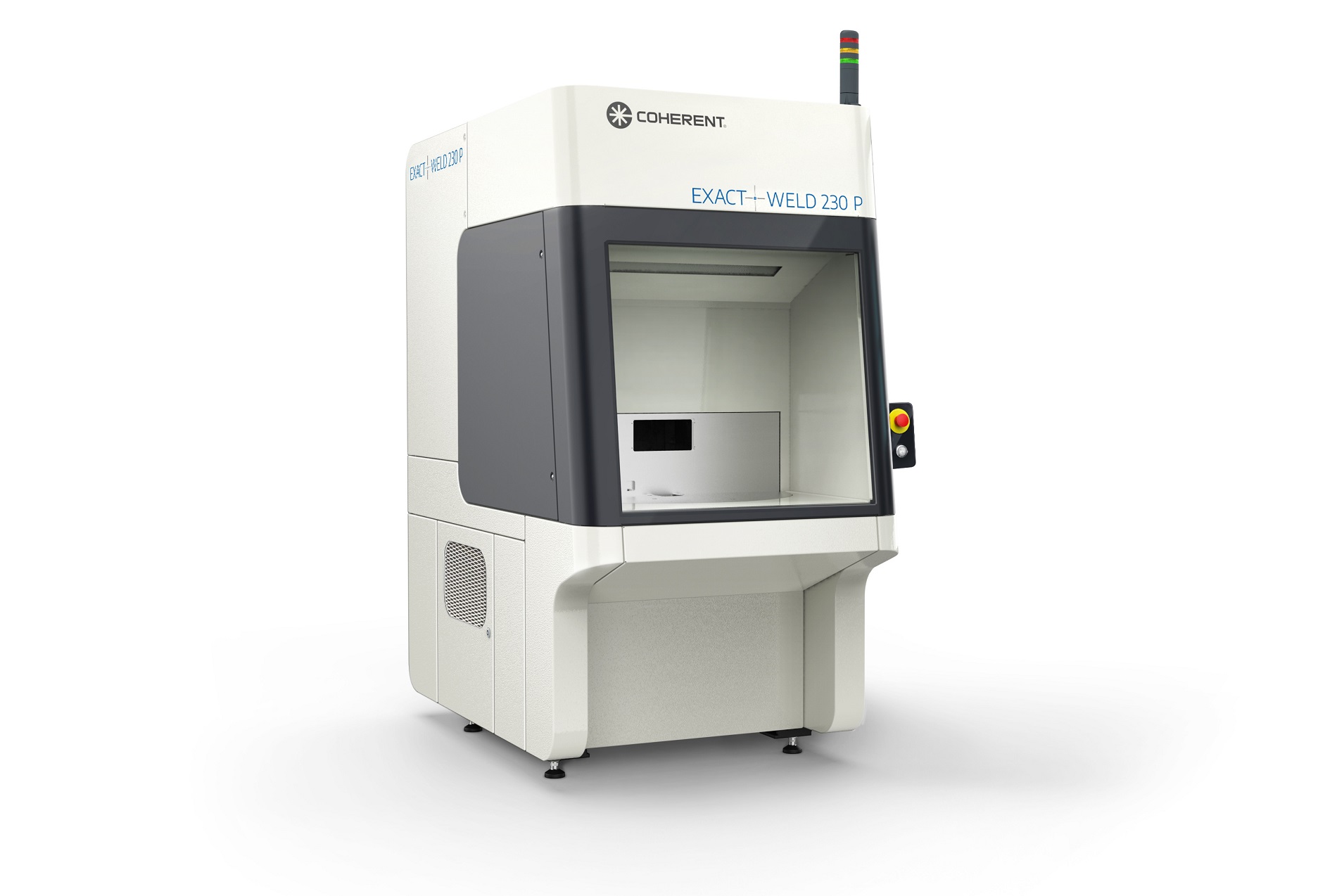

Santa Clara, CA, June 10, 2019 – The new Coherent ExactWeld 230 P enables particle-free high throughput welding of small to medium sized polymer parts. It combines a diode laser, servo-controlled clamping and responsive software to deliver distortion-free weld quality and rapid cycle times. An available vision system is designed to further enhance productivity by providing continuous weld quality assessment, correct product placement and automatic part offset correction. We believe these capabilities make ExactWeld 230 P an ideal solution for polymer part joining in automotive displays, instrumentation, sensors and lights, medical equipment, housings and tube connectors, as well as consumer electronics and appliances.

At the heart of ExactWeld 230 P is a galvanometer scanned diode laser that enables quasi-simultaneous welding over complex contours (over areas of up to 420 mm x 200 mm). With a range of available laser wavelengths and power options, the system can be optimized for specific materials and tasks, and is optionally available with a fiber laser to deliver the thinner weld seams required in some applications. A sophisticated servo-controlled part clamping system can be precisely configured for complex parts, and a rotary table speeds part loading/unloading and enhances throughput. To complete the package, Coherent’s worldwide service team and experienced applications specialists provide comprehensive support, including process optimization to assist customers in developing applications-specific “recipes.”

Other ExactWeld 230 P options include software for database interfacing (SQL), robotic part handling, and RFID recognition to enable seamless integration into a multitude of manufacturing environments.