2018/10/22

Hamamatsu Photonics (Hamamatsu, Japan - President and CEO: Akira Hiruma) has developed a compact tabletop size power laser system that emits high-power light pulses of 1 joule at a high repetition rate of 300 hertz by using laser diodes as pumping light sources that provide an output power boosted 3 times compared to ordinary pumping laser diodes. Increasing the output power of laser systems usually has an adverse effect on equipment size and repetition rate. This new power laser system solves that problem and delivers high output power and a high repetition rate despite its compact size.

This new power laser system improves production efficiency in laser machining processes such as laser cleaning for removing small debris and contaminants and will also find uses in new applications such as laser forming for fabricating metal materials by laser pulse shock and laser peening for extending lifetime of metal parts.

This new power laser system was developed by the team of Toshiyuki Kawashima, Deputy Director of the Industrial Development Center, Hamamatsu Photonics Central Research Laboratory. Part of this laser system’s development relied on a R&D program called “Ubiquitous Power Laser for Achieving a Safe, Secure and Longevity Society” managed by Yuji Sano program manager under the ImPACT Program (Impulsing Paradigm Change through Disruptive Technologies) sponsored by the Japanese Cabinet Office Council for Science, Technology and Innovation. We intend to push ahead to develop this power laser system toward its successful commercialization. This newly developed power laser system will be on display at the Hamamatsu Photonics exhibition “PHOTON FAIR 2018” to be held at Act City Hamamatsu (Naka-ku, Hamamatsu City, Japan) for 3 days starting from November 1 (Thursday).

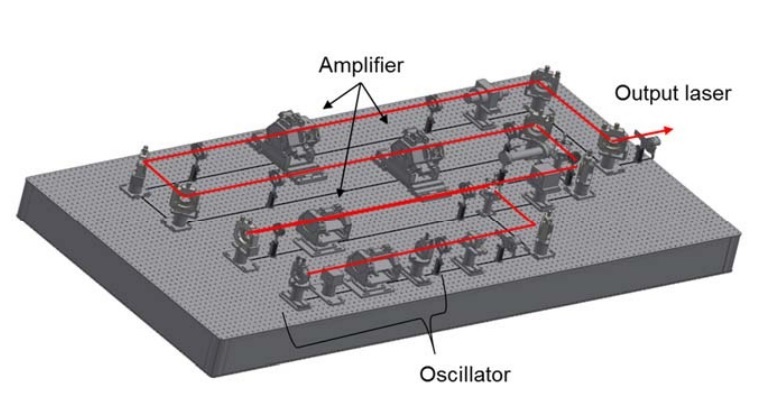

This power laser system mainly consists of an oscillator and amplifiers. The oscillator is made up of a pumping laser diode, laser medium, total reflection mirror, output mirror and optical switch. Each amplifier uses a pumping laser diodes and a laser medium. A laser beam emitted from the oscillator is supplied with energy from three laser media at a higher energy level (excited state) as it passes through the amplifiers and is finally output as a high power beam.

Overview of power laser system

This power laser system contains pumping laser diodes that we also newly developed, and emits high-power light pulses of 1 joule at a high repetition rate of 300 hertz despite its compact tabletop size.

Hamamatsu Photonics already produces and sells pumping laser diodes capable of a 100 watt output at a repetition rate of 300 Hz. We have boosted the output power of our currently available pumping laser diodes to the world’s highest 300-watt class by using our unique inhouse advanced crystal growth and coating technologies. At the same time, we adapted an efficient cooling design for the amplifiers by adjusting and optimizing the laser medium length and cross-sectional area. This eliminated the problem of thermal damage and destruction of the laser media and succeeded in extracting output power that is 3 times larger than present amplifiers.

Configuration of power laser system

Using laser diodes as pumping light sources increases electrical to optical energy conversion efficiency about 10-fold and extends the pumping light source service life about 100-fold compared to commercially available pulsed laser systems using flash lamp light sources. We also succeeded in improving the output stability, downsizing equipment, and cutting the cost by reducing the number of parts. Although increasing the output power of laser systems usually has an adverse effect on the equipment size and repetition rate, the power laser system we created delivers a high output power and high repetition rate despite its compact size.

This new power laser system will improve production efficiency in laser processes such as laser cleaning for removing small debris and contaminants adhering to parts and materials. This power laser system will also likely provide new pulsed laser applications in industrial fields such as laser forming that deforms and shapes metal materials for aircraft without using molds, and laser peening that extends the lifetime of metal parts.

Lasers are widely used in machining and processing applications such as drilling, welding and cutting of metal materials. To improve production efficiency, unceasing efforts are being made to increase the output power of various lasers including fiber lasers and CO2 lasers.

Lasers are broadly classified into CW (continuous wave) lasers that continuously emit laser light of constant intensity and pulsed lasers that emit pulsed light repeatedly at very short time intervals. Laser processing applications mainly rely on CW lasers. Pulsed laser design, on the other hand, is directed toward new laser processing applications that differ from CW laser applications. Yet, high output power, high repetition rate laser-diode-pumped pulsed laser systems are seldom put to actual use due to the high cost of laser diodes.

Consequently, most currently available joule-class pulsed laser systems use flash lamps as the pumping light source. In these pulsed laser systems, the lamps generate heat and large thermal effects that limit the repetition rate to around 10 hertz. These problems and the need to increase production efficiency in an even broader range of applications have led to an increasing demand for compact power laser systems that emit high-power pulsed light at a high repetition rate.

Hamamatsu will continue their design and improvement work to successfully commercialize this power laser system by measures including further downsizing and streamlining maintenance.