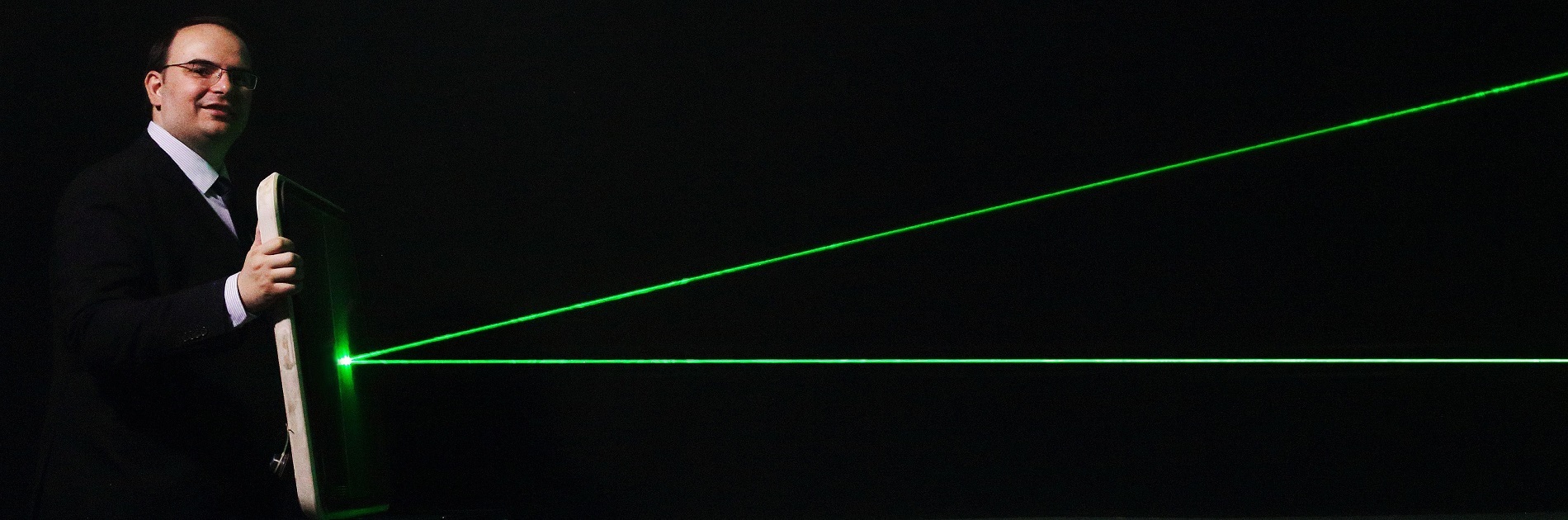

Halifax, N.S. February 21, 2017 – Metamaterial Technologies Inc. (MTI) and its optical filters division, Lamda Guard, announced today, February 21st, that it has entered into a new agreement with leading aircraft manufacturer Airbus to validate, certify, and commercialize its laser protection product metaAIR™, for aviation. In 2014, MTI signed its first agreement with Airbus to test and tailor metaAIR™, which is a flexible metamaterial optical filter, engineered to protect vision against harmful laser beams aimed at aircraft.

Laser strikes on commercial aircraft are rising globally and laser pointers are increasing in power and decreasing in price. Lasers can distract pilots during critical phases of flight and can cause temporary visual impairment. In 2015, according to the Federal Aviation Administration (FAA), the number of reported laser incidents nearly doubled to 7,703 in commercial aviation. In 2015, there were 1,439 laser incidents reported to the Civil Aviation Authority (CAA) in the UK and there were almost 600 reported by Transport Canada

“We know from facts and conversations with clients that cockpit illuminations are real, immediate and increasing in frequency, and metaAIR will benefit our customers,” said Pascal Andrei, Vice President, Chief Product Security Officer at Airbus. “We also see an increasing number of possible applications for metaAIR, beyond the commercial aircraft division.”

MTI is a great example of Airbus “start-up 2 partner” program led by Elsa Keïta from Airbus Corporate Innovation. This program aims at building mutually beneficial partnerships with disruptive innovators and Airbus has been working in a successful and collaborative approach with MTI to accelerate their laser protection solution for the benefit of its customers.

“Our objective is to place Canada and its citizens on innovation’s leading edge. The presence of Airbus here today demonstrates that highly skilled Canadian researchers and entrepreneurs, like those at MTI, are creating innovative solutions to global problems,” said the Honourable Navdeep Bains, Canadian Minister for Innovation, Science and Economic Development and Minister responsible for the Atlantic Canada Opportunities Agency.

“We look forward to continuing our relationship with Airbus as we move to commercialize metaAIR. Together we will be able to make a positive impact on the aviation industry around the world,” said Maurice Guitton, MTI Board Chairman.

“Today marks another milestone in our strategic partnership with Airbus. We are given the opportunity to propel our platform technology and learn from some of the top aerospace engineers while understanding the rigours of developing a product for the aerospace industry,” said George Palikaras, MTI Founder and CEO. “metaAIR will provide vision protection to pilots in the aviation industry and can offer solutions in other industries including the military, transportation and glass manufacturers.”

MTI has also developed a partnership with Covestro, one of the world’s leading companies for high-tech polymers. Covestro supplies a custom Bayfol® HX photopolymer film for the manufacturing of metaAIR™.

“MTI is at the cutting edge of optical applications. They have developed a unique optical filter that is different from anything currently available on the market, and we have been working with them for the last two years to provide a speciality photopolymer material film and support the required volume,” said Thomas Fäcke, responsible for marketing and business development of photopolymer films at Covestro. “Safety is very important to our company, and we are excited to be a part of this solution.”

About Metamaterial Technologies Inc.

Metamaterial Technologies Inc. (“MTI”) is a smart materials and photonics company specializing in metamaterial research, nanofabrication, and computational electromagnetics. The company has developed a new class of optical smart materials, changing the way we use, interact and benefit from light. MTI is headquartered in Halifax, Nova Scotia and has offices in London, England and Pleasanton, California. To learn more visit www.metamaterial.com