Santa Clara, Calif., 08/03/2017– New, high power ultraviolet (355 nm) and green (532 nm) additions to Coherent’s popular AVIA industrial nanosecond laser family extend and improve the performance of microprocessing applications in microelectronics, photovoltaics and related industries. Specifically, the new AVIA 355-55 features a very high (150 kHz) pulse repetition rate, resulting in an average power of 55 watts at 355 nm. The AVIA 532-80 produces high (1 millijoule) pulse energy, which, together with a maximum pulse repetition rate of 80 kHz, translates into an average power of 80 watts.

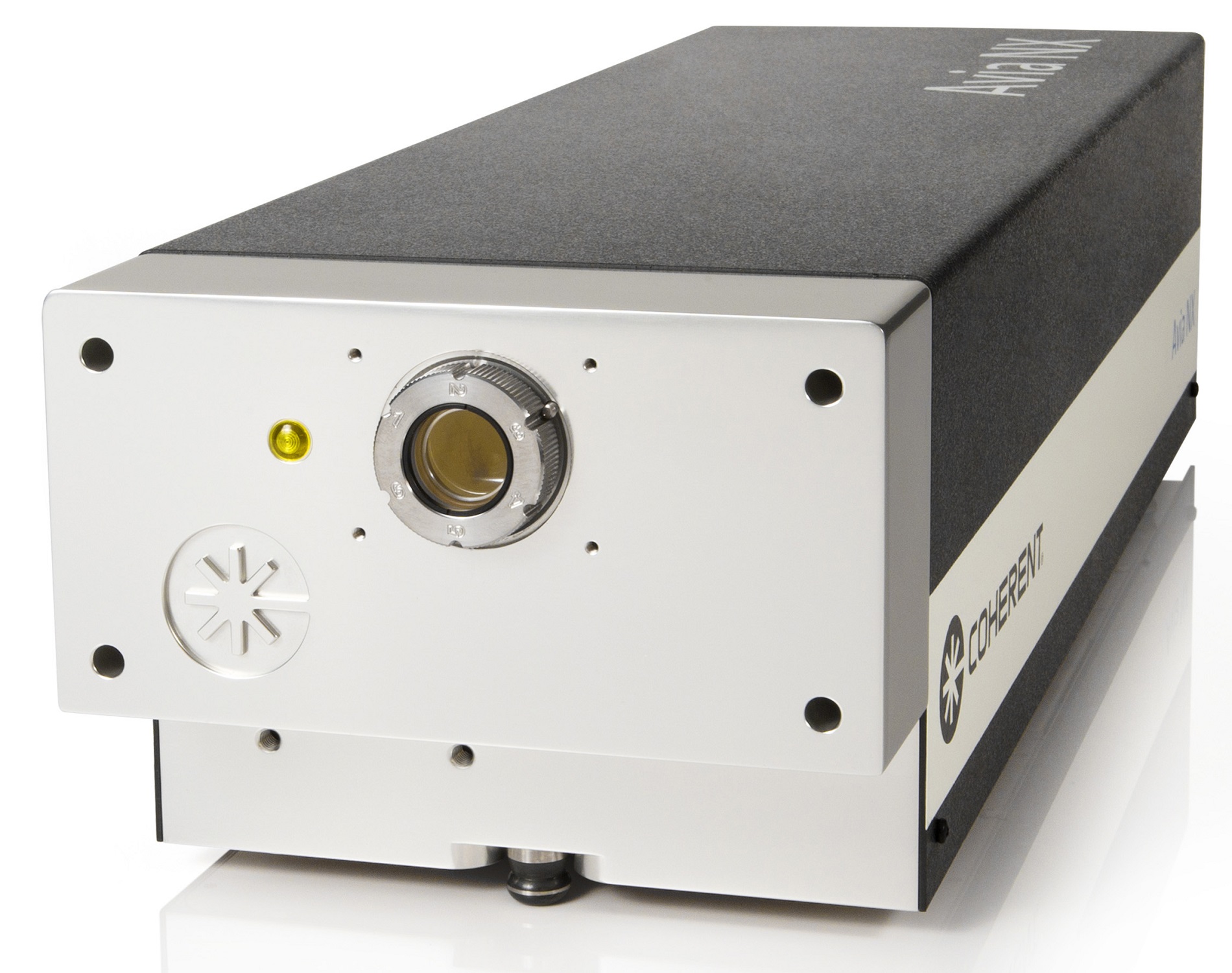

Coherent AVIA lasers are compact, rugged, vanadate lasers that are well-established in many microprocessing applications because of their superior performance. Just as important, they deliver unmatched reliability and longevity through the use of Highly Accelerated Life Testing (HALT) protocols, which identify failure mechanisms so that they can be designed out. Then, individual production units are tested using Highly Accelerated Stress Screening (HASS) methods. Coherent is the only laser manufacturer to employ this stringent HALT/HASS stress testing methodology, which identifies and eliminates any potential reliability issues with products before they are shipped to the customer, without decreasing their useful life. This minimizes cost of ownership for these lasers.

AVIA ultraviolet lasers are used for cutting flex substrates and thin printed circuit boards (PCBs) where higher lateral resolution (i.e., precision xy features) are a critical consideration. The higher power now available from the new AVIA 355-55 will extend these cutting capabilities to thicker (> 200 µm) flex and multi-layer materials. It will also enable existing applications to be accelerated to higher throughputs, while still delivering the same superior edge quality with minimal peripheral thermal damage.

AVIA green lasers are used for scribing films, drilling holes and slots, and cutting flex substrates that efficiently absorb green wavelengths, including certain PCB substrates, semiconductors, and photovoltaic components. The unique, high pulse energy of the new AVIA 532-80 provides high piercing capabilities for drilling, cutting and scribing, deeper features and thicker substrates than competitive lasers. And the 80 kHz repetition rate ensures high process throughput.