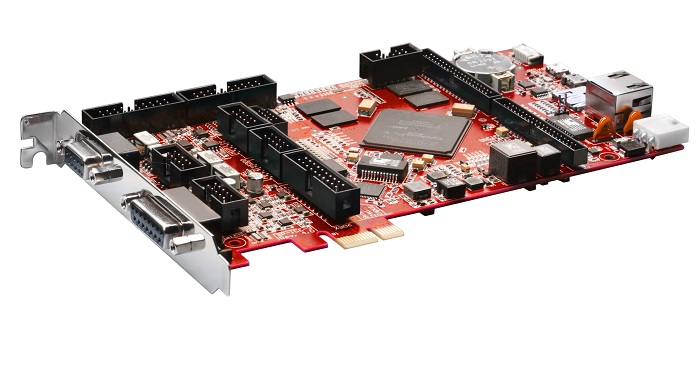

Wessling, Monday, 4. July 2016 – RAYLASE, the expert in laser scanning heads, is simplifying and accelerating the development of laser systems with its new SP-ICE-3 universal control card. It controls 2-axis and 3-axis deflection units as well as all standard laser sources. Furthermore, offers speed-dependent and position-dependent control for a consistently high processing quality. Its extended marking-and-processing on-the-fly (MOTF) functionality and highly configurable I/Os make it the ideal choice for highly complex laser systems with deflection units.

Material processing using lasers has now become an essential part of many manufacturing processes. This processing includes the engraving of components, perforation of packaging, cutting of cardboard or metal places or the welding of plastics. "Because we develop and offer both components and solutions for laser material processes, we at RAYLASE have the necessary experience to understand exactly what system developers need", explains Berthold Dambacher, Member of the Executive Board of RAYLASE AG with responsibility for Development. "This is the basis on which we developed the SP-ICE-3 control card, which is so easy to use that it enables fast, easy development of classic laser systems. At the same time, it offers such a wide range of configuration options that even highly complex and specific functions can be implemented using the SP-ICE-3".

Thanks to its impressive range of features, the SP-ICE-3 has a wide range of applications:

- 2 GB DDR3 RAM for memory and field corrections in 2D and 3D

- 32 GB Micro SD card for settings, programs and lists

- PCIe 2.1 and GigE interface for PC integration or stand-alone operation

- Three 16 bit I/O ports, e.g. for controlling up to 4 step motors

- Two 24 bit LVCMOS ports, e.g. for customer-specific enhancement cards

- Two quadrature decoders for MOTF processing

- RS232 and USB 2.0 ports

The performance data also speaks for itself:

- 20 bit position resolution with the SL2-100 protocol (16 bit with XY2-100). This allows the mirrors to be controlled with a resolution of 0.75 µrad.

- 10 µs step period and up to 16 MHz laser frequency

The SP-ICE-3 scanhead control card makes beam guidance in the shape of circular arcs, ellipses or text characters easier than ever before. It offers out-of-the-box functions for marking consecutive serial numbers or the current date or time. A new bitmap mode "draws" images with up to 1 MHz pixel frequency and 15 ns resolution. For MOTF applications , two quadrature decoders with differential inputs track the movement of the conveyor belt in the direction of belt travel and in the orthogonal direction. This ensures that the laser job can also be executed correctly on components while they are moving. For detailed diagnosis, system optimization or monitoring, the SP-ICE-3, controlled by list or control commands, is capable of recording up to 24 million measured values from the various channels that can be selected.

These and other functions, the simple way of programming (e.g. with C#) and the high level of reliability, which you can always presume at RAYLASE, are capable of meeting the most challenging requirements of developers, allowing them to focus on the speedy implementation of their laser systems.

About RAYLASE AG:

Lasers are a fascinating and versatile tool for industry and research. The employees at RAYLASE AG have made it their goal to make it easy for manufacturers, integrators, plant manufacturers, and researchers to take advantage of the diverse possibilities opened up by laser technology. RAYLASE supplies high-precision components and submodules for high-speed deflection and modulation of laser beams. They are at the heart of industrial laser systems for applications such as marking, textiles, welding of metals and plastics, or for additive manufacturing and cutting of materials such as thin foils. Numerous customers throughout the world value the individual service, expert design, fast development, and reliable delivery of tailored solutions.