29 Nov 2016

by Roddy Isles

Pioneering laser technology could boost the performance of the Large Hadron Collider (LHC) at CERN to new levels of efficiency, helping unlock some of science’s greatest mysteries going back to the `Big Bang’.

The technology for the surface modification of metals known as LESS (Laser Engineered Surface Structures) for this specific application is the result of a collaboration between the University of Dundee and the Science and Technology Facilities Council (STFC).

Dundee and STFC have now entered into partnership with CERN to employ the new technology, which is aimed at clearing the `electron cloud’ that develops in the LHC and limits the range of experiments that it can handle.

Professor Amin Abdolvand, Chair of Functional Materials & Photonics at the University of Dundee explains, “Large particle accelerators such as the Large Hadron Collider suffer from a fundamental limitation known as the `electron cloud’. This cloud of negative particles under certain condition may degrade the performance of the primary proton beams that circulate in the accelerator, which is central to its core experiments.

“Current efforts to limit these effects involve applying composite metal or amorphous carbon coatings to the inner surfaces of the LHC vacuum chambers. These are expensive and time consuming processes that are implemented under vacuum.”

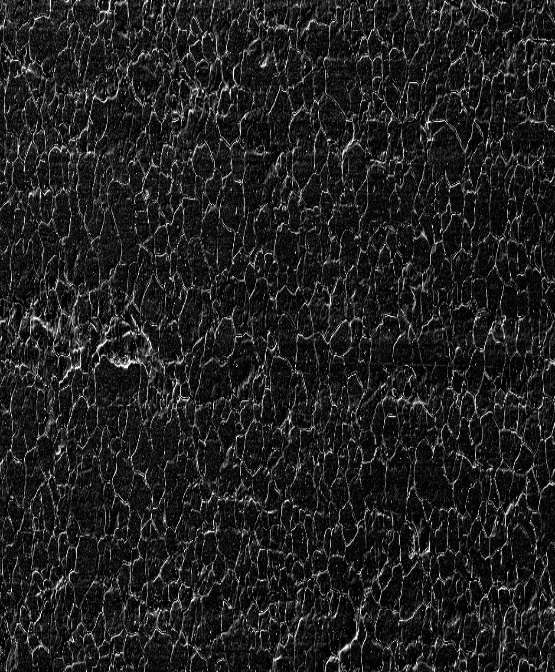

Metal before treatment

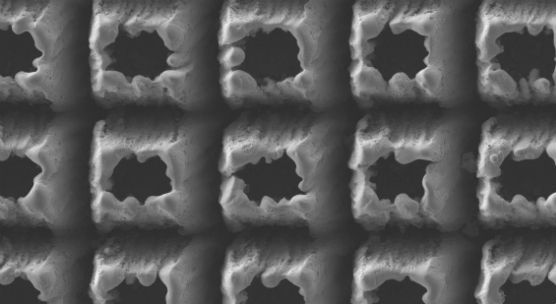

Metal after treatment

In the frame of the High Luminosity LHC project, CERN is preparing to upgrade the collider from 2019 and a new solution is needed to reduce the electron cloud problem to much lower levels than are expected as the upgraded collider will use proton beams of double the intensity of the current ones.

The LESS method has shown potential to reduce the electron cloud to unprecedentedly low levels. It involves using lasers to manipulate the surface of metals, and relies on understanding how different metal surfaces react when they are subjected to varying levels of laser fluence or intensity.

Tests have shown that it is possible to reformulate the surface of the metals in the LHC vacuum chambers to a design that under a microscope resembles the type of sound padding seen in music studios. The surface can trap electrons, keeping the chambers clear of the cloud. Initial tests at the Super Proton Synchrotron, the LHC injector, have shown the LESS method is very effective at controlling the electron yield, as electron clouds have been fully eradicated.

Peter McIntosh, Deputy Head of STFC ASTeC (Accelerator Science and Technology Centre), added “The LESS method should yield many successful applications in the future; this is just one opportunity that will have a dramatically positive impact for the LHC and its High Luminosity configuration.

“Through close working interaction between ASTeC vacuum scientists and Dundee University laser specialists, a real breakthrough in suppression of secondary emission yield performance has been accomplished, which could have widespread implications for high electro-magnetic field environments, where breakdown limitations are of particular concern, such as for sensor systems and applications in satellite and aerospace technologies.

“We expect it will prove to be an innovative solution for CERN.”

Professor Lucio Rossi, Project Leader of the High Luminosity LHC, said, “If successful, this method will allow us to remove fundamental limitations of the LHC and reach the parameters which are needed for the high luminosity upgrade in an easier and less expensive way. This will boost the experimental program by increasing the number of collisions in the LHC by a factor over the present machine configuration.”

Michael Benedikt, Head of the Future Circular Collider study at CERN, said “The LESS solution could be easily integrated in the design of future high-intensity proton accelerators; the method is scalable from small samples to kilometre-long beam lines.”

The University of Dundee is one of the world’s top 200 universities and in 2016 was named Scottish University of the Year for the second consecutive year (Sunday Times Good University Guide). Dundee is internationally recognised for the quality of its teaching and research and has a core mission to transform lives across society.

Both Times Higher Education and QS World University Rankings have ranked Dundee best in the UK and one of the top 20 worldwide among universities under 50 years old. Our students also rate us very highly on student satisfaction – we are one of the UK’s top ten in the National Student Survey 2016, and first for personal development of students.

See www.dundee.ac.uk for further details.