May 25, 2016

From May 31 to June 2, 2016, Jenoptik’s Automotive and Healthcare & Industry divisions are going to present themselves at LASYS, the only international trade fair that is clearly focused on laser material processing. Jenoptik’s booth is D13 in hall no. 4.

The lasers, processing optics and laser machines produced by Jenoptik are suitable for diverse application purposes: for the cutting of highly complex 3D vehicle body parts and structural components, for the welding of various interior and exterior components, and for the integration of invisible pre-determined breaking points into sensitive materials. Besides lasers and optical systems for laser material processing, Jenoptik is going to present a live demonstration of the 3D robotic system for the processing of bumpers at the trade fair at LASYS in Stuttgart, hall 4, booth D13.

Complex 3D processing with new machine concepts by Jenoptik

In order to meet the ever-increasing challenges of the automotive industry in terms of lightweight construction and material saving in the production process, Jenoptik has developed machine concepts specifically for the processing of bumpers. These concepts utilize two technologies which have been successfully introduced into the market by Jenoptik: 3D laser cutting and laser welding. By combining one laser cutting unit and one laser welding unit, Jenoptik presents a highly flexible solution for the processing of a vast variety of bumpers.

The first step in the maximum-precision processing of bumpers in the predetermined cycle time is the 3D laser cutting of the bumper. Laser cutting facilitates high-efficiency processing of complex 3D components – bumpers being a perfect example. The non-contact process protects materials and minimizes costs which would otherwise occur due to long set-up times or tool wear. Additionally, laser cutting ensures a high degree of edge quality.

In the second step, different components such as mounting brackets for parking sensors or the headlight cleaning system are welded onto the inside of the bumper in the welding unit. Laser welding creates high-strength welding connections without penetrating the substrate too deeply and potentially causing damage. The material thickness of the bumper can therefore be reduced to 2.7 mm or less. The automotive manufacturer thus benefits from material savings and weight reduction.

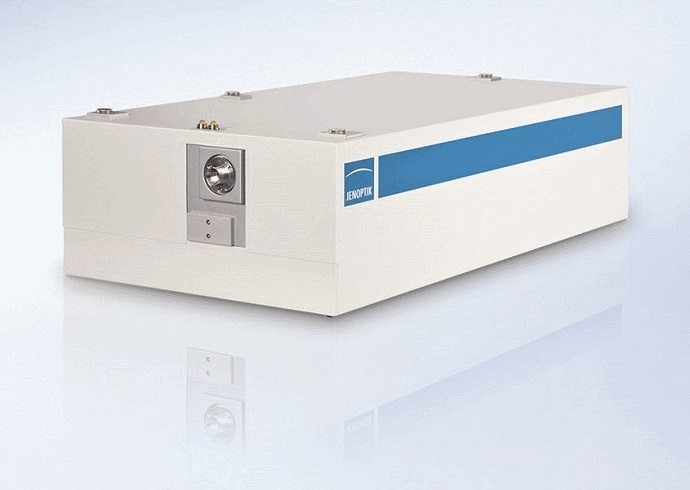

New femtosecond laser for industrial micro material processing

Jenoptik has been producing beam sources for more than 20 years, and already ten years ago introduced one of the first femtosecond lasers for industrial use into the market. At LASYS 2016, the company will present the newest advancement of its established JenLas®femto series – the JenLas® femto 16. Next to its well-known advantages like high pulse energies, a free adjustable pulse repetition rate, and single pulse capability, the newest version convinces with an integrated SHG option. The JenLas® femto 16 can be easily and quickly integrated into laser machines for reliabe 24/7 operation.

Consequent product development and an increase of output power enable users to address new fields of application, like machining of organic, inhomogeneous materials (e.g. genuine leather), as well as to increase the productivity of known applications. For instance, the drilling of injection or extrusion nozzles for automobile or textile industries benefits from the high available pulse energy by enabling a significant reduction of process time and an improved surface and edge quality.

Femtosecond thin disk lasers like the JenLas® femto series provide an outstanding machining quality that saves post processing steps like deburring by means of electro-polishing.

The short pulse duration of about 550 femtoseconds facilitates processes such as

- non-thermal ablation of nearly all materials (damage- and burr-free processing of polymers, nitinol, etc.)

- non-linear absorption in transparent materials (efficient machining of sapphire or glass)

- material-selective ablation in multi-layer systems

- inner marking of transparent materials

- machining of organic, inhomogeneous materials like genuine leather.

Besides laser sources, Jenoptik delivers optical accessories such as circular polarizers, beam expanders or F-theta objective lenses. The company also offers the development of customized optical solutions from laser to the focus for healthcare and industrial laser applications, as well as worldwide application and service support with subsidiaries in Europe, in the U.S, and APAC regions.

Learn more on Jenoptik’s new website www.jenoptik.com.