10 September 2015

Two-dimensional crystals are very suitable for creating high-quality magnetic thin films. This appears from two recent publications written by scientists from the University of Twente's MESA+ research institute. The researchers show that by growing the magnetic layers on various 2D crystals, better known as nanosheets, you can control the preferred direction of the magnetism very locally. In an article published in Advanced Functional Materials, they present this method to create magnetic patterns on the micrometer scale. In Angewandte Chemie, they demonstrate that you can make the nanosheets in less than a minute, while the synthesis process had been known to be very slow. The magnetic films can be deployed for many different applications, such as new generations of smartphones.

With pulsed laser deposition (PLD) you can achieve controlled growth of thin layers of certain materials. Here, a material is heated rapidly with a powerful laser beam, so that it evaporates and a plasma is created. This spreads quickly in a vacuum chamber and is deposited on a substrate where it forms a thin layer. In this way you can control the thickness of the layer and you can form smooth and thin layers, often with special properties that are interesting for use in electronics and electro-mechanics, for example. For such applications, it is however essential that you can also make patterns in the layered materials. This is not easy, especially because the substrate needs to be heated to temperatures above 500° C during the PLD process. Many of the existing methods are therefore not adapted to existing manufacturing methods for microstructures.

Use of nanosheets

The UT researchers have now developed a new method, in which they make use ofnanosheets obtained from three-dimensional crystals with a layered structure. If you dissolve these crystals in a special liquid, they spontaneously disintegrate into individualnanosheets. It was long thought that the crystal disintegration process could take weeks. However, the researchers have now shown that the nanosheetsare already able to form within a few seconds, which opens the way for the production ofnanosheets on a large scale.

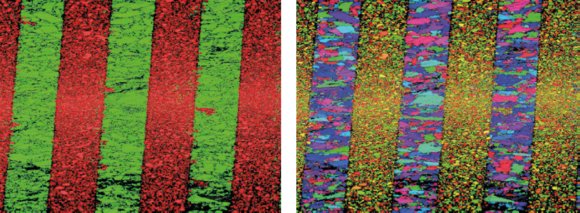

Based on the solution, various nanosheetscan be introduced in micro-patterns on a substrate. These patterns form the starting point for the growth of thin magnetic layers of magnetic LaSrMnO3 at high temperatures by means of PLD. Depending on the type ofnanosheet the structure of the magnetic film assumes a specific orientation, and thus determines the magnetism of the film at that location. The process is monitored by means of, for example, electron backscatter diffraction (EBSD); a technique that makes it possible to 'reveal' the structure in the patterns.

FUNCTIONAL PROPERTIES

The researchers show that you can use the micro patterns to control the functional properties of a material in detail. In addition to magnetism, it is possible to pattern other properties at the micrometer scale. An important step has thus been taking in bridging the gap between scientific research into artificial layered crystals and their ultimate application. The group from Twente plays a leading role in this worldwide.

RESEARCH

The research was performed by scientists from the Inorganic Materials Sciencedepartment of UT research institute MESA+. It forms part of the TOP project funded by the Netherlands Organisation for Scientific Research (NWO) and the Chinese Scholarship Council. The research involved close cooperation with the Condensed-Matter and Medical Physics group at the University of California (UC, Irvine).

Publications:

Maarten Nijland, Sean Thomas, Mark A. Smithers, Nirupam Banerjee, Dave H.A. Blank, Guus Rijnders, Jing Xia, Gertjan Koster and Johan E. ten Elshof, “Epitaxy on Demand,”Advanced Functional Materials 2015, 25, 5140–5148.

DOI: 10.1002/adfm.201501483

Huiyu Yuan, David Dubbink, Rogier Besselink and Johan E. ten Elshof, “The Rapid Exfoliation and Subsequent Restacking of Layered Titanates Driven by an Acid–Base Reaction,” Angewandte Chemie International Edition, 2015, 54, 9239 –9243.

DOI: 10.1002/anie.201502539