Sep, 29th 2015

Pulsed laser diodes are becoming more and more efficient and powerful. Thus, they represent a viable alternative to large and expensive laser systems. One advantage of solid-state lasers is the very good beam profile. Achieving this with semiconductor laser diodes requires the use of external beam-shaping elements or homogenizers. Diffusing lenses, diffractive elements, or long optical fibers may be used; however, in all of these approaches either power is lost or the mechanical effort is very large.

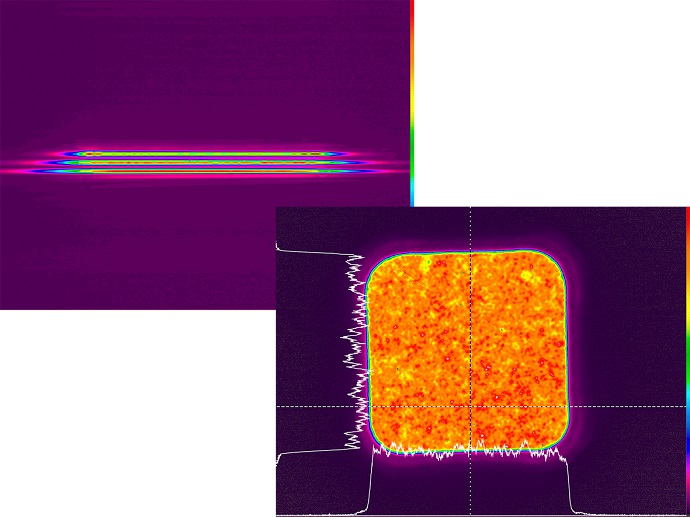

LASER COMPONENTS‘ developers in Canada were successful in connecting powerful, multi-junction PLDs to a special fiber structure, thus allowing a homogeneous beam profile to be achieved after just a few centimeters. Picture 1 shows the near-field distribution of a pulsed laser diode with three epitaxially-integrated emitters. After just 13 mm, a significantly more homogeneous beam profile is visible. Picture 2 shows the beam profile after 55 cm. The advantage of this assembly is that it is compact and robust and simultaneously exhibits low losses and thus a higher peak power. Prototypes are currently being built. LASER COMPONENTS is still able to include any desired changes.

Further product information:

Pulsed Laser Diodes