02 Jun 15

Novel self-cleaning, high temperature and corrosion resistant optical windows developed at DTU Nanotech enable the development of a novel gas analyser system. Improved measurement, control and ultimately the reduction of environmentally harmful and toxic gas emissions from marine vessels will be possible.

Driven by the upcoming regulations of the International Marine Organisation (IMO), global efforts to reduce the air pollution by ships especially in near shore areas are increasing. The new regulations comprise tighter demands on shipowners to minimise and monitor harmful and toxic gas emissions such as NOx (NO, NO2) and SOx (SO, SO2) from their vessels. These gases are known to contribute to the formation of acid rain and smog. They also cause irritation and damage to the human respiratory system.

Researchers at DTU Nanotech and their partners from industry and universities share a common final goal: To provide shipowners with a tool to reliably monitor ship emissions in one of the harshest environments, i.e. directly in the exhaust gas of a marine diesel engine.

As stated by Per H. Rasmussen from Maersk Maritime Technology: “It is essential for shipowners to have reliable tools to analyse emissions because of the IMO regulations. And the most reliable way to monitor emissions would be to have a direct, continuous analysis of the exhaust gas. Furthermore, real-time exhaust gas monitoring of SOx may become mandatory.”

Harsh conditions demand innovative solutions

Ship exhaust gas is highly contaminated with tons of particles, shows a temperature of up to 500 °C and can contain corrosive substances like sulphuric acid. To build a robust gas analyser system that can measure reliably and directly in such harsh conditions over long time is a great challenge.

René Bergmann, Researcher at DTU Nanotech, explains: “As when you are looking through a window, so a gas sensor for direct gas measurement looks into the gas through an optical window and measures its composition with infrared light. In a way, the window serves as a pair of “protective glasses” for the sensitive sensor elements.”

Usually optical infrared windows cannot reliably sustain the very harsh environment of the exhaust gas, as the contamination, high temperature and corrosive environment will destroy important functional coatings on the windows. This causes errors in readings or total failure of the sensor function.

Robust sensor enabled by novel “protective glasses”

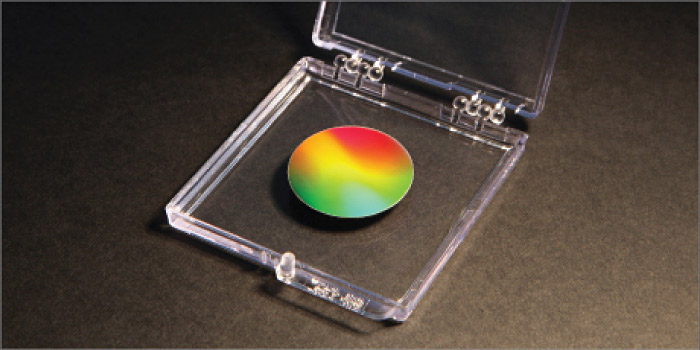

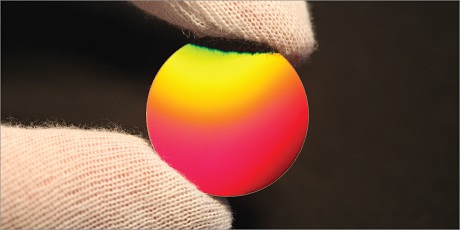

At DTU Nanotech an advanced type of optical infrared windows with favourable properties has been developed. The new “protective glasses” for the novel multi-gas analysers will ultimately possess three features, achieved by an innovative micro/nano surface modification and proper material selection.

- Self-cleaning surface properties, resulting in no or less effort to clean the surface from contamination.

- High durability and transmittance even at high temperatures (up to 500°C) to ensure the functionality as a window.

- High corrosion resistance so that the windows resist most acids and bases.

“These properties make our windows superior compared with existing optical windows. The windows will enable our partner Green Instruments A/S, a sensor manufacturer, to build a revolutionary multi-gas analyser system that can measure directly on the ship exhaust gas.” says René Bergmann.

By applying the new windows, the novel system will operate faster, in real-time and more precisely, thereby resolving major and decisive issues with present sensor systems. “With the new sensor, shipowners can document that they comply with the regulations. At the same time, the information about NOx content in the exhaust can be used to adjust the operation of the ship’s engine to use the fuel as economically as possible”, explains Poul K. Sørensen, Executive Technical Advisor of Green Instruments A/S.

First sensor prototype already tested

A first gas analyser prototype including the advanced protective optical windows has been built together with Green Instruments A/S, DTU Kemiteknik, DTU Compute, and IPU. This proof-of-concept prototype system was recently tested on board a ship provided by the project partner A. P. Møller-Mærsk A/S. The result of this test was very promising with regard to the final development of the novel multi-gas analyser system.