June 25, 2015

Champlin, Minnesota: Prima Power announced the introduction of its new LASERDYNE 430 Versa 3D fiber laser system with third generation BeamDirector®. Versa is designed for the typical laser processing needs of tool rooms, model shops and R&D centers of manufacturers.

This system provides the optimum balance of cost, flexibility, and precision for laser cutting, welding, drilling, texturing, and marking of a wide range of materials. The 430 Versa also provides a cost effective path into volume production by making possible the full benefits of fiber laser processing with an effectively priced workstation.

The 430 Versa is equipped with an air-cooled 3000 W peak power fiber laser and the proprietary LASERDYNE BeamDirector. The BeamDirector provides two axes of laser beam motion without part movement. The 430 Versa also provides precision through the use of the same design and technology as LASERDYNE systems used in aerospace and medical device production around the world. Precision comes not only from the performance and accuracy of the 430 Versa motion system but also from advanced LASERDYNE exclusive features that allow the fiber laser to effectively perform a full range of tasks. This is the result of integrated control of the laser, motion and processors. Precision is not only measured by the accuracy and repeatability of the machine tool but more importantly by the parts produced on the system.

Also, integral to the 430 Versa are Laserdyne advancements in processing using the fiber laser. These include recently announced innovations in processing such as SmartPierce™, SmartRamp™, SmartStop™, and ShapeSoft™ -- all resulting from Laserdyne research.

Adding to the 430 Versa’s flexibility are the proven features of the LASERDYNE S94P control, with a full complement of standard hardware and software features. These include Automatic Focus Control™ (AFC) for capacitive part sensing, and as an option, the patented Optical Focus Control (OFC) for sensing of non-conductive surfaces.

The 430 Versa also includes a wide range of standard focusing lens assemblies including right angle assemblies for processing inside cylinders having diameters as small as 60 mm and welding assemblies that shield the weld metal to prevent contamination and protect the focusing lens from spatter.

Both the capacitive and optical methods of focus control precisely guide the motion system, maintaining critical focus position and following the contour of the part regardless of surface irregularities. The linear axes of the system react to sensing of the part surface, creating unlimited correction along the axis of the beam. The combination of crash protection and part sensing gives the system operator confidence to use the maximum processing speed possible without fear of damaging the system or scrapping the part.

Important to developers of new part designs and manufacturing processes using laser, the 430 Versa features industry leading collision protection backed by a five year, unlimited hours warranty covering crash related damage to the head.

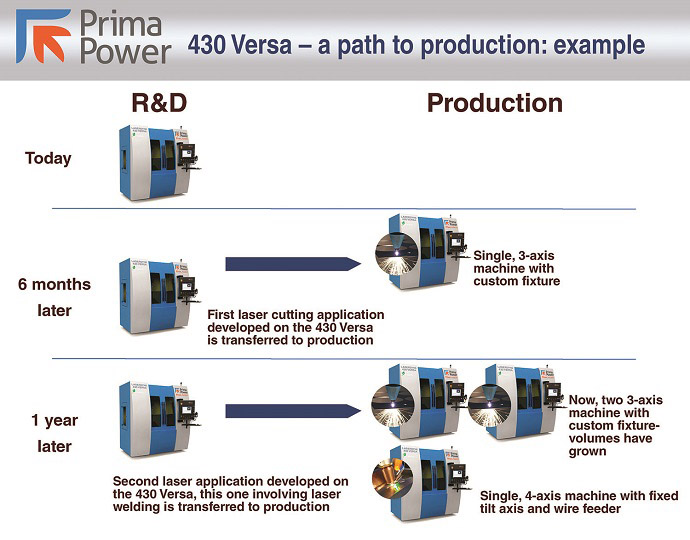

How The Laserdyne 430 Versa Facilitates Prototype Into Volume Production

The 430 Versa provides an ideal path to progressively higher production quantities as a new product design is tested, modified where necessary, re-tested and produced in increasing quantities. This is accomplished using the same basic laser system platform of the original LASERDYNE 430 Versa system – the same control and machine structure. These are easily adaptable to the specific requirements of the developed manufacturing process. This is done through the selection of the motion axes, beam delivery optics and tooling. Using this method, the optimum balance of cost, performance, system simplicity and ease of operation is accomplished as shown in the following series of photos and captions.

“The affordability of the 430 Versa and the many advantages of fiber laser processing provides will create the possibility for new part designs within companies that are working to reduce the time from concept to manufacturing of new products,” stated Mr. VanderWert. “Our goal at Prima Power Laserdyne is to continue to produce advancements that expand the use of laser processing and ultimately make our customers more successful,” he said.

For more information: