June 4, 2015

Reflection of light off glass surfaces is a problem occurring in everyday life, and hinders the performance of solar panels, smart phone and tablet displays. Researchers from FOM institute AMOLF have found a new and simple method to eliminate this reflection, by printing a silica nanopatterned antireflection coating onto the device

The reflection of light from a material is determined by the refractive index. Glass, a material commonly used in solar panels and displays, has a refractive index of 1.5 and reflects 4% of incident light at its surface. The reflectivity can be reduced applying an anti-reflection coating, which must have a refractive index of 1.2 to eliminate the reflection completely. However, materials with such a low index do not exist in nature.

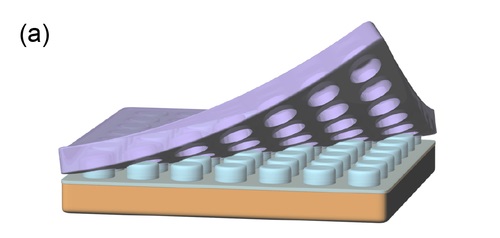

The AMOLF team used soft-imprint technology to fabricate an array of nanoscale glass cylinders onto a glass substrate. The effective index of this coating is determined by the density of the glass cylinders and was made to match exactly 1.2. By doing so, the combined reflectivity of the two sides of the glass substrate was reduced from 7.4% to 0.6%. The low reflectivity is maintained over a large range of angle of incidence, up to 50 degrees.

Photograph of reflection of fluorescent lighting off a smartphone screen with (bottom) and without (top) the nanopattern AR coating. A strong reduction in the brightness of the reflection is clearly visible.

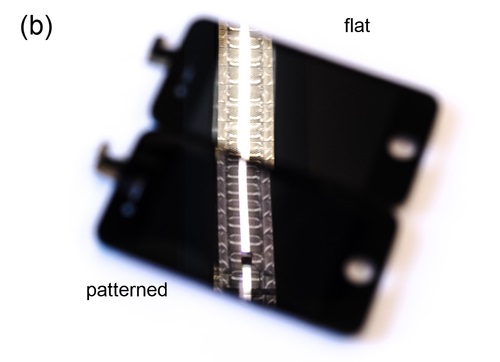

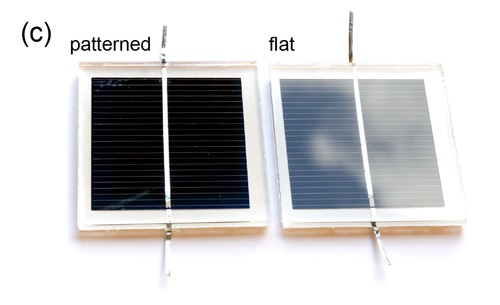

Soft-imprint lithography uses a flexible rubber stamp that transfers a nanoscale pattern into a liquid silica solgel layer that is first spin-coated on the glass substrate. After drying, the nanocoating is robust and water repellant. The researchers applied the nanocoating on miniature solar panels and showed that their efficiency increases by 2.8%. They also show how the glare from a nano-coated smartphone screen is effectively eliminated.

Photograph of glass-encapsulated solar cells with (left) and without (right) nanopattern AR coating. The reflection of the clouded sky is clearly visible in the flat cell, whereas the patterned cell is completely dark.

Albert Polman: “These experiments are the proof-of-principle. The next step is to exploit the fact that nanoimprint lithography can be expanded to an industrial scale, and work with manufacturers of solar panels and displays to apply our new, patented technology.”

Reference

Jorik van de Groep, Pierpaolo Spinelli, and Albert Polman

Single-step soft-imprinted large-area nanopatterned anti-reflection coating

Nano Letters (2015) | DOI: 10.1021/acs.nanolett.5b01623