October 06, 2015

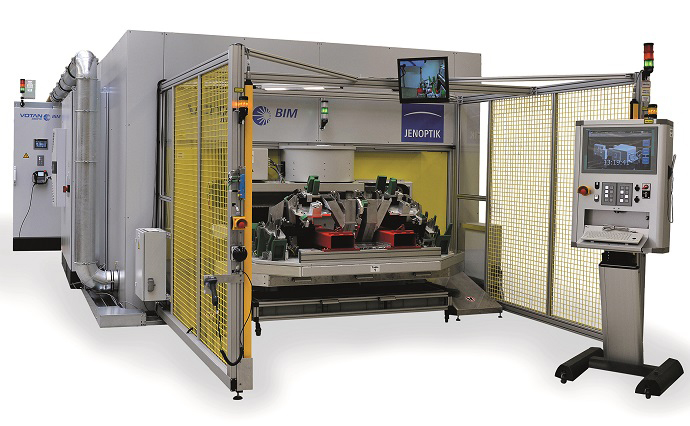

Laser cutting allows a highly efficient processing of complex metal parts. The non-contact process minimizes costs caused by set-up time or tool wear. Due to its design and high flexibility, JENOPTIK-VOTAN® BIM is the ideal, virtually wear-free tool for processing of a variety of metal working parts, even if the manufacturer processes on only one laser machine, because there is no need to use special cutting dies as during the conventional processing. With a repeat accuracy of up to 50 µm, this laser machine ranks among the most precise systems of its class. Moreover, the axis movements of the robot’s laser arm are up to 60 percent faster than the ones of the current robot standards, thus allowing for a significantly shorter cycle time compared to other robot systems.

The system concept of the JENOPTIK-VOTAN® BIM series is based on a beam guide inside the robot. This allows using laser sources with a power of up to 4 kW without having to use a complex external beam guide. At the same time, the equidistant beam path prevents the laser beam from pumping effects, ensuring a stable beam quality. This approach allows Jenoptik to deliver its customers a technological competitive advantage.

With its metal cutting laser machine series, Jenoptik serves the automotive industry by cutting e.g. complex car body and structural parts as well as hydroformed tubes, being used for exhaust systems or car body rail manufacturing. JENOPTIK-VOTAN® BIM is simple to integrate into production lines or combined processing units.

Watch a live demonstration of the robot at Jenoptik’s booth 6087 in Hall North 2 at the FABTECH trade show in Chicago, IL USA from November 9 to 12.

About the Jenoptik Lasers & Material Processing Division

With its Lasers & Material Processing division, Jenoptik is one of the leading providers of laser technology and provides products and solutions along the entire value-added chain of laser material processing – from components up to complete laser systems. In the Lasers business unit, the company has specialized in high-quality semiconductor lasers, reliable diode lasers as modules or systems as well as innovative solid-state lasers such as disk and fiber lasers. This product portfolio makes Jenoptik the ideal partner for the entire pulse width range, from cw to fs. In the field of high-power diode lasers, the company is acknowledged as a worldwide quality leader.

In the Laser Processing Systems business unit, Jenoptik develops and manufactures laser machines which are integrated into its customers’ production lines as a part of their process optimization and automation. They serve for the processing of plastics and metals. Jenoptik laser systems ensure processing at maximum efficiency, precision and safety. In addition, customers can try out various laser sources and machines at the Application Center, thus finding the optimal solution for their application. The product portfolio is rounded off with energy-efficient and environmentally friendly exhaust cleaning systems for residue-free removal of pollutants during laser processing and other industrial processes.

Jenoptik presents fast and precise 3D metal cutting laser machine at FABTECH

At FABTECH, North America’s largest trade show for metal processing technology, Jenoptik will demonstrate its laser machine series for 3D metal cutting.

JENOPTIK-VOTAN® BIM for laser cutting