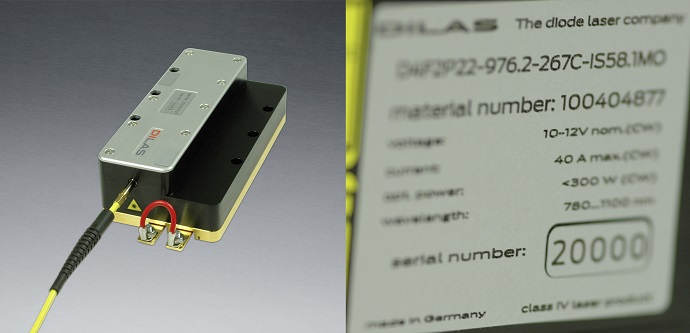

MAINZ, Germany, May 7, 2015 – DILAS, the diode laser company, celebrated the delivery of its 20,000th, high-power, high-brightness, tailored bar-based (T-Bar), fiber laser pump module. Shipping its first unit in 2009, this milestone product was designed and developed as a pump source for kilowatt class fiber laser systems. Planned as a volume product from the very beginning, the production process has a high degree of automation. Through the optimization of semiconductor chip structures and optical parameters, DILAS’ T-Bar architecture delivers high beam quality and high power using standard micro-optic fast-axis collimators (FAC) and slow-axis collimators (SAC), all assembled with automated processes. The T-Bar is a monolithic multi-emitter source allowing the handling of multiple emitters during each manufacturing step, to lower complexity and ease manufacturing. The result is enhanced reproducibility, beam quality and fiber-coupling efficiency.

Conservatively specified to 135W out of 200µm, NA0.22 when designed, the T-Bar module was later increased to 200W out of 200µm by optimizing the chip structures and fiber coupling processes. Today DILAS’ latest generation has a higher density of tailored diode laser bars with an output power at 250W out of 200µm, and 270W out of 225µm. Whereas the fiber connector was intentionally detachable in the early phase, it turned out that the diode laser module is no longer considered a spare part. The latest generation is delivered with a non-detachable pigtailed fiber.

Joerg Neukum, DILAS’ Director Sales and Marketing, notes, “This milestone for tailored bar-based fiber laser pump modules reflects DILAS’ commitment to supporting our customers with diode lasers that combine cutting edge performance in high-brightness, high-power and high reliability.”

Within the tailored bar platform series, DILAS offers a number of other pump modules in different wavelengths and power.

For more information, please visit www.DILAS.com