Ditzingen, December 21, 2015 – The performance capacities of the 2D laser machines and the solid-state lasers made by TRUMPF continue to advance. Just as in previous years, TRUMPF has unveiled technology highlights at each trade fair, redefining the standards for cutting with a solid-state laser. Worthy of special mention are the BrightLine fiber function, which turned the solid-state laser into an all-purpose tool, and the CoolLine feature. The latter stabilizes the cutting process for thick mild steel by way of closely defined cooling. This makes it possible, for instance, to cut extremely tight curves. At this Blechexpo in Stuttgart TRUMPF once again introduced new innovations that will make a decisive advance in laser cutting.

Smart Beam Control

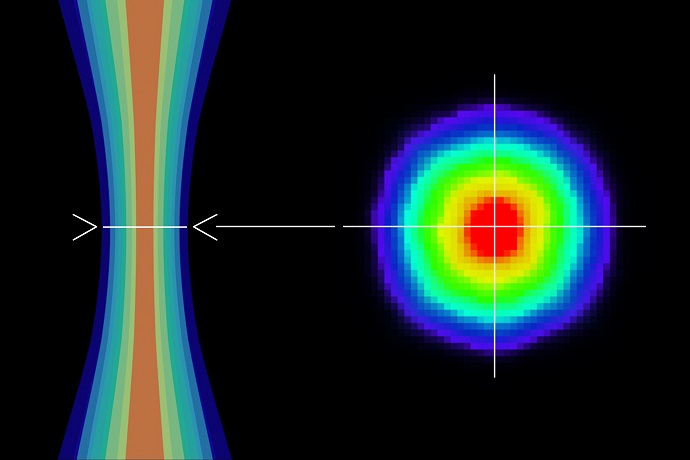

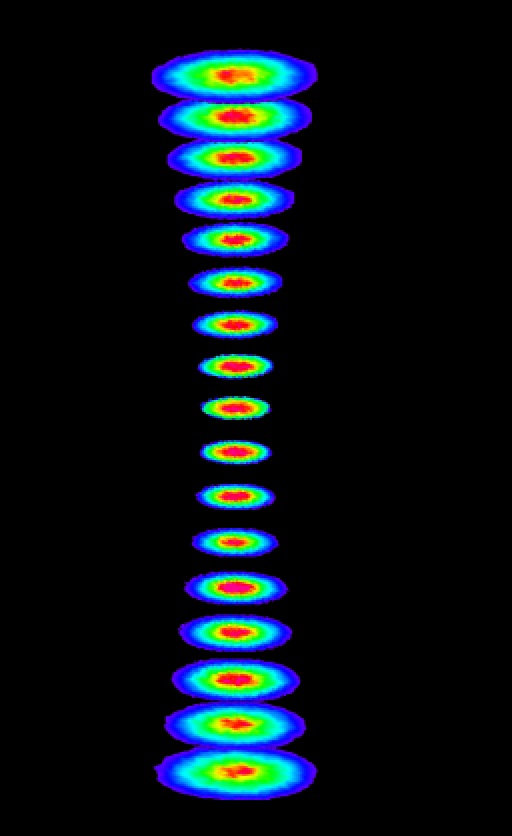

The Smart Beam Control function automatically regulates the focal position of the laser during cutting and, in this way, ensures consistently high process reliability. In addition, a diagnosis of the cutting system is possible – also from a remote location, using Teleservice.

Photo: TRUMPF

Among these features is the intelligent beam monitoring system – Smart Beam Control. It lends even greater reliability to the solid-state laser machines in the TruLaser Series 5000. Smart Beam Control automatically regulates the laser’s focal position during the cutting process itself. This function makes for constant superior reliability and makes it possible, in addition, to carry out a diagnosis of the cutting system. This can also be done from a remote location, using Teleservice.

The new Condition Guide function for the TruLaser Series 5000 enhances transparency. A single glance is enough to determine the machine’s status. A traffic light system provides information on the condition of key elements that affect the machine’s cutting capacity. The Condition Guide can, if desired, provide information on corrective actions to be taken by the operator. Line charts show the history of the particular condition and simplify forecasting the need for intervention. Consequently, maintenance work can be planned both efficiently and in harmony with actual needs.

Smart Beam Control

The Smart Beam Control function automatically regulates the focal position of the laser during cutting and, in this way, ensures consistently high process reliability. In addition, a diagnosis of the cutting system is possible – also from a remote location, using Teleservice.

Photo: TRUMPF

TRUMPF also showed the TruLaser 5030 fiber in Stuttgart with new laser power. In addition to the three, five and eight kilowatt power levels offered in the past, the machine is now also available with the six kilowatt TruDisk 6001 laser. Especially at medium and heavy sheet metal gauges this makes for quick processing. Using the TruDisk 6001 and the functions cited here the TruLaser 5030 fiber cuts mild steel, stainless steel and aluminum up to 25 millimeters thick and copper and brass as much as 10 millimeters thick, both quickly and with enviable dependability.