22 September 2014

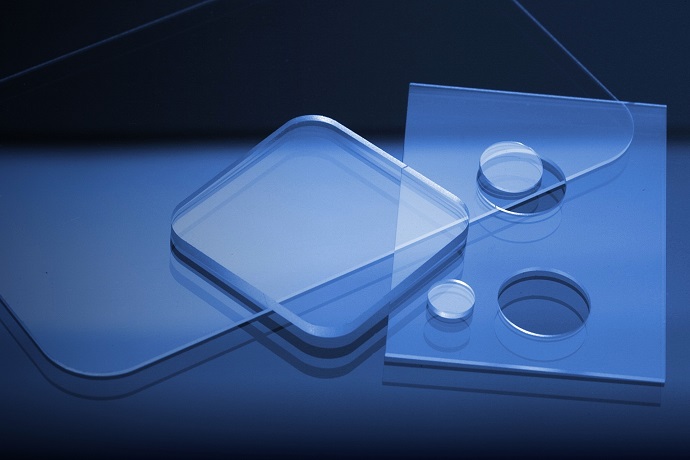

In a year when global shipments of smartphones and tablets are expected to surpass 2 billion units, the ability to cut glass and similar materials is critical.

Television screens, computer screens and smart watches also need tough screens which must be cut at production speeds with perfect quality.

ROFIN is now able to offer the SmartCleave™ FI laser cutting process, which is the most-advanced, all-laser cutting process for glass, sapphire, ceramics and other transparent, brittle materials.

Cutting display glass can be massively improved

Cutting glass with conventional, mechanical methods - like diamond scribing and breaking - is a fairly inexpensive process, but it comes with significant drawbacks due to relatively low scribing quality (micro-cracks, chipping) and accuracy. Typically, a number of additional time-consuming process steps like grinding, masking and etching are necessary to remove the damage introduced by these mechanical processes, as well as to eventually achieve the required tolerance of the outer dimensions of the parts. Furthermore, mechanical methods quickly reach their limits, when complex geometries, like small radii, have to be generated. When using mechanical methods, tool wear and the applied forces can lead to a significant amount of glass breakage and reduced production yields. As a result, the glass manufacturing industry is always looking for alternative technologies to cut glass and other brittle, transparent materials with low damage and higher yields.

Limited laser cutting alternatives so far

Some laser processes are already used in glass manufacturing, but so far a single laser process has not been able to provide a comprehensive solution. Currently, lasers are used to drill holes or cut complex shapes using laser ablation with excellent quality. But these processes are far too slow to be applied to a full device. Fast laser processes, like CO2-laser cutting still show accuracy limitations, especially when it comes to contour cutting. So, today it is typical to find a combination of laser and mechanical processes in the production of glass or sapphire-based devices.

SmartCleave™ FI - a true game changer

SmartCleave™ FI is a kerf-less separation process for strengthened (chemically and thermally) and non-strengthened glass of 100 µm to 10 mm thickness and other brittle materials. Cutting speeds higher than 300 mm/s can be achieved. Straight, curved, angled and chamfered contours are possible, as well as cutting of tubular or curved parts or stacks.

SmartCleave™ FI offers unmatched cutting quality with minimal micro-cracking and chipping and a surface roughness of Ra < 1µm. Parts cut with SmartCleave™ FI retain high bend strength and require minimal post-processing.

Compelling economics

Depending on material and thickness the parts are self-cleaving or just require little force or stress to cleave. This leads to a dramatic reduction of process steps and higher yield in industrial mass production. And finally it's a green technology without water use.

IP protected and unique

Through a recently-completed asset deal, ROFIN acquired all intellectual property including trademarks, know-how, patents and patent applications of FiLaser USA LLC which are the foundation of SmartCleave™ FI. This technology opens the door to huge application area, especially but not at all limited to the consumer electronics area.