August 8th 2014

No suitable process control method for laser processing of fiber-reinforced plastics is currently available. Therefore scientists at the Laser Zentrum Hannover e.V. (LZH) are now working together with the Sensortherm GmbH and Newson nv on an innovative double scanner processing head: In this processing head, the beam path of the processing laser is decoupled from the detection beam path used for temperature measurement. This makes it possible to have spatially flexible and temporally high-resolution measurements during the processing of fiber-reinforced plastic.

The combined scanning head should make it possible to measure any point within or without the laser interaction zone, during the running process. In order to achieve this, the project partners decouple the laser beam path from the path of the high speed pyrometer. In this process, the measurement beam of the pyrometer will be guided by separate scanner mirrors. These are especially tuned to the detection wavelength of the pyrometer.

Process control for fiber-reinforced plastic materials

Highly accurate online temperature measurement is especially important for laser processing of fiber-reinforced plastic materials, such as carbon fiber reinforced plastics (CFRP). With the combined scanning head and the associated measurement method, thermally critical areas in the processing geometry can be accurately monitored. This principle builds the foundation for active intervention in the process and its optimization.

While the LZH is developing the affiliated laser processes and the process control for welding and cutting of fiber-reinforced plastic materials, Newson nv, Berlare-Overmere, Belgium, is developing the actual combined scanning head. An innovative, high speed pyrometer for different wavelength ranges is being adapted to this processing head by Sensortherm GmbH, Sulzbach/Taunus. Furthermore, Sensortherm is optimizing this pyrometer for laser transmission welding, and for laser cutting and material removal. The use of the combined scanning head is not limited to laser processing of fiber-reinforced plastic materials, meaning that metals or glass materials, for example, can also be processed.

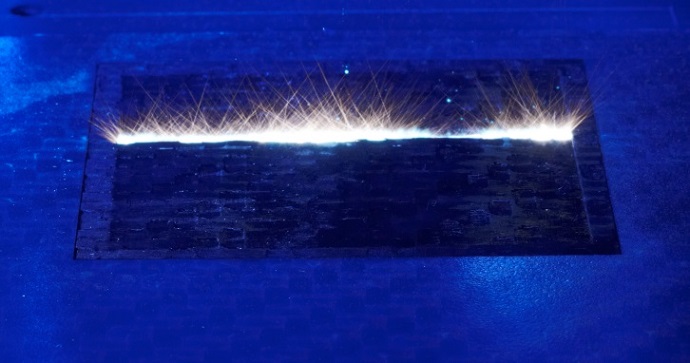

Caption for figure 2: With the combined scanning head, the CFRP processing and the measurement can be decoupled. Illustration: LZH

The European EraSME project A'Quilaco (Advanced online quality and process control for high speed laser machining of composites) started on January 1st, 2014, and will run for two years. In Germany, A'Quilaco is financially supported by the Federal Ministry for Economic Affairs and Energy (BMWi), and in Belgium by the IWT "agentschap voor Innovatie door Wetenschap en Technologie".

Further information: http://www.lzh.de/en/projects/a-quilaco