June 24, 2014

Champlin, Minnesota: Prima Power Laserdyne has made significant investment over the past several months in developing process and system capability for welding 2D and 3D components with high power CW and QCW fiber lasers, reports Terry VanderWert, president.

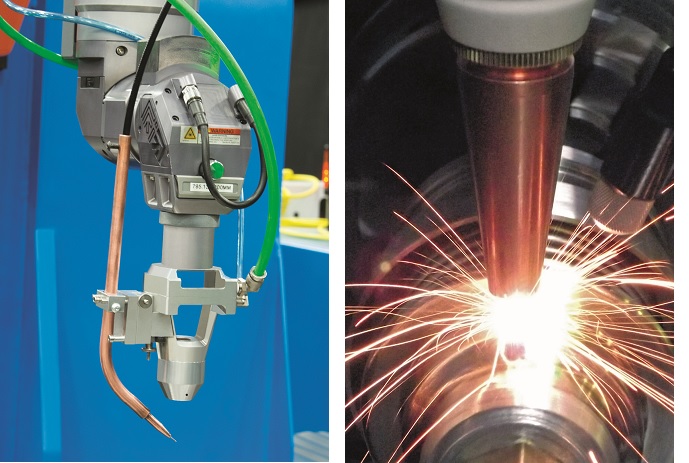

“Metals and alloys for which these capabilities have been demonstrated include 304 stainless steel, titanium alloys including Ti-6A1-4V and Ti-6Al-2Sn-4Zr-6Mo and nickel based high temperature alloys including Inconel 625, Inconel 718 and Hastelloy X,” reported Mr. VanderWert. “The availability of the high power CW and QCW fiber laser with its kilowatt-level average power, 1 micrometer (µm) wavelength, and high brightness (beam quality) provides a laser source with new capability and flexibility.” (Photos One and Two)

Mr. VanderWert stated that “compared to CO2 lasers for welding, it is well documented that the 1 µm wavelength of the fiber laser provides benefits in terms of simplified beam delivery using fiber optic cables instead of turning mirrors; greater absorption by metals, especially those which are good conductors of electricity such as aluminum and copper; and less absorption by the plasma plume that is formed above the weld pool. The higher brightness of the fiber laser compared to high power Nd:YAG lasers means that the laser beam, if desirable, can be focused to smaller sizes which, in turn, leads to increased power density. These factors contribute to deeper penetration and faster welding speed than available from previous sources of equivalent average power. They also mean more stable welding processes in a wider range of metals and alloys.”

While the LASERDYNE® product line began with laser welding, wide acceptance of the Laserdyne brand and technology is for laser cutting and drilling for aerospace applications. Over its 33 year history of what is now Prima Power Laserdyne, laser welding systems have been supplied for aerospace (engine and airframe), automotive, electronics, fluid couplings, and medical device applications using CO2, Nd:YAG and more recently, fiber laser sources.

Increased Variety Of Power Levels Of CW and QCW Fiber Lasers On Standard Laserdyne Products Enable Welding A Wide Range Of Metals And Alloys

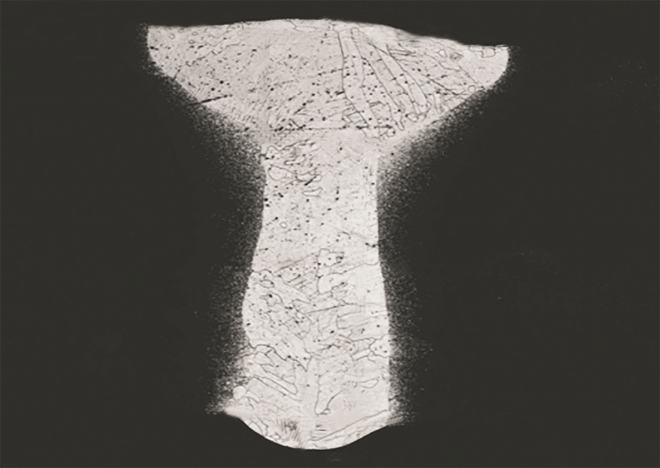

Recently, Laserdyne has integrated fiber laser sources with their standard systems. Welding trials using a range of laser parameters and shield gases were performed. Metallography (cross-sections) and X-ray radiography were used to document the relationship between laser (spot size, laser power, etc.) and processing (shield gas type, gas flow rates, method of gas delivery, welding speed, focus position, etc.) parameters and the resulting weld geometry and structure. For example, the trials showed conditions that lead to weld porosity and those that give porosity-free welds. These trials also showed the relationship between laser and processing parameters on weld shape and profile.

Photo Three Caption: Laserdyne fiber laser welding technology has proven to yield the correct weld geometry for aerospace and other alloys. These trials included using a range of laser parameters and shield gases.

The most comprehensive investigation has recently centered on laser welding aerospace alloys. (Photo Three) The major challenge for these materials is the stringent joint requirements. There is no tolerance for cracking or porosity in the weld. The weld geometry must be correct with good mechanical properties at high temperatures. Testing by Prima Power Laserdyne has proven that both CW and QCW fiber lasers are capable of welding these alloys.

However, the challenge lies in developing and consistently delivering laser and processing parameters which will produce quality welds. Laserdyne has developed the laser and processing parameters to weld the full range of aerospace alloys. Laserdyne’s studies prove that no single parameter controls weld quality, whereas, it is a combination of both laser and processing parameters that have a significant effect on the weld quality. These studies also show that crack and porosity-free welds can be readily produced in a range of nickel and titanium based alloys.

Laserdyne CW and QCW Fiber Lasers Equipped With Wire Feed

Laserdyne’s welding trials included those with addition of filler wire. Certain alloys and dissimilar material combinations require the addition of filler material to control the structure of the weld metal and avoid cracking to ensure the required mechanical properties. In other cases, filler metal is used to control the weld geometry, such as to create a slight convexity (reinforcement) of the weld fusion zone. Filler material is also used to compensate for poor fit up and mismatch during laser welding in a butt joint configuration. Laser welding with the filler wire is a multi-parameter process and there are a number of laser and filler wire parameters which determine the quality of the resultant weld. Laserdyne has developed and optimized all of the important parameters for adding filler material to produce quality welds.

Laserdyne Testing Leads To New Laser System Features

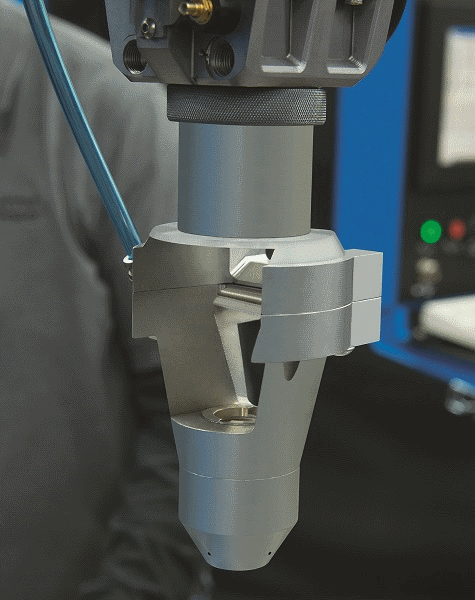

One significant development is a new focusing lens assembly with cross-jet design that maintains the compact profile of the LASERDYNE third generation BeamDirector®, called BD3Y. The cross-jet feature provides a high velocity gas barrier that prevents metal sparks in the weld zone from contaminating the protective lens cover slide. Critical to this design is that the cross-jet prevents contamination or interference with the welding shield gas. Also important, Laserdyne’s cross-jet nozzle can be used with the entire range of shield gas delivery devices including welding shoe and coaxial gas nozzle tip. (Photo Four)

The shielding gas shoe provides a controlled atmosphere for the weld zone while it is molten and cooling to a temperature level that won’t be compromised by the ambient atmosphere. This is important when welding materials, such as titanium alloys, that have a strong affinity for oxygen and nitrogen in the ambient atmosphere. Another important benefit of the focusing lens/shield gas assembly design for laser welding is that they are quickly changeable in order to vary the focused spot size.

Photo Four Caption: Laserdyne’s cross-jet nozzle assembly prevents damage to the focusing lens and protective cover slide while avoiding contamination or interference with the welding shield gas ensuring quality welds with the correct geometry.

Enhanced Fiber Laser Control Results In Higher Quality Welds

Laserdyne’s new laser control capabilities, notably laser power ramping and laser pulse shaping with sub-millisecond resolution, has been demonstrated using the LASERDYNE S94P control. This higher level of control leads to more consistent, higher quality welds. It increases the flexibility of LASERDYNE systems in terms of broadening the range of materials which are now being laser welded. Pulse shaping has been shown effective in controlling the weld profile and structure. This is accomplished by controlling the temperature profile during weld formation and during cooling of the weld and heat affected zone.

For example, providing a lower amplitude portion of the pulse after the initial portion controls cooling of the alloys that harden during rapid cooling. Another example, is the use of pulse shapes with a higher amplitude on the leading edge for materials that are reflective to the laser beam even at 1 micrometer wavelength. Rapidly heating the surface leads to increased absorption of the laser beam and a more consistent process.

“All of the features described have been standardized and are available on the entire Laserdyne product line of 3 to 7 axes systems including LASERDYNE 795 and LASERDYNE 430BD,” stated Mr. VanderWert. “These are exciting times as our laser system technology is growing rapidly and solving new and difficult manufacturing challenges.”

More information at: