Ditzingen, June 24, 2014 – TRUMPF is launching its new generation of direct diode lasers. The TruDiode 4506 is making its world premiere. With 4.5 kilowatts of power and beam quality of 30 mm*mrad, it opens the door for classical deep welding applications with diode direct lasers in this performance class. With its efficiency of up to 40 percent, the new TruDiode 4506 is superbly energy-efficient and thus is well suited for “green production”, something being sought ever more vigorously in industrial manufacturing.

Thanks to its compact design, with external measurements of just 750 x 870 x 1325 millimeters, the resulting small footprint of only 0.65 square meter and its modular engineering, the new TruDiode 4506 can be integrated in existing production systems both easily and without complication. The flexible beam guidance by laser light cable is making a contribution here. Passing through the 600 micron core diameter in that cable, the beam reaches the processing optics and ultimately the workpiece. With appropriately adjusted optics the required spot size can be created quickly and easily. It is important to know that the 4.5 kilowatt output from the TruDiode 4506 is transmitted directly to the workpiece – the laser beam will have already passed through the laser light cable and the processing optics. The specified 4.5 kilowatts of power are actually applied to the workpiece.

These are ideal prerequisites for conventional welding applications and this is what TRUMPF is focusing on with this new direct diode laser generation: deep welding and heat conduction welding. During the intensive process of deep welding, the laser welds through the full depth of the material, achieving great strength in the final piece. By contrast, heat conduction welding with the new TruDiode 4506 creates a clean and visually appealing welding seam. At the same time, this new TruDiode generation is also suitable for surface finishing processes, including hardening, soldering and deposition welding. Thus, the target market is the entire sheet metal processing industry.

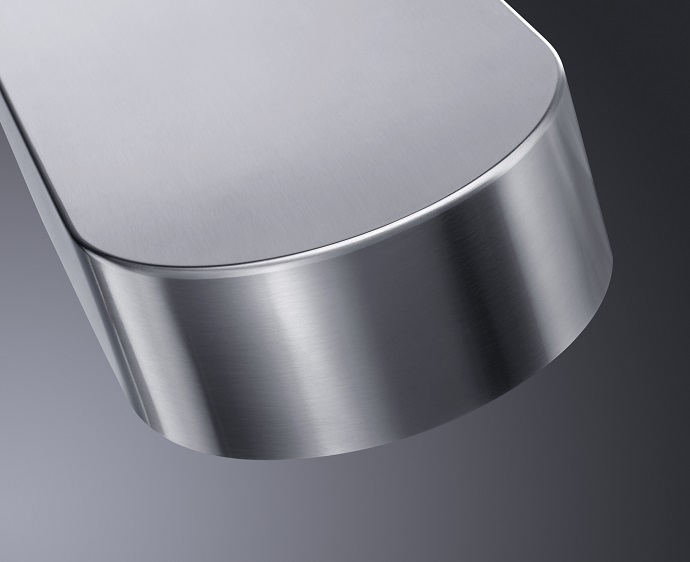

With the new diode direct laser generation, TRUMPF is focusing on deep welding and heat conduction welding. Shown in the photograph is a laser-welded chain guard.

The TruDiode 4506 is also flexible in its operating modes. Whether as a stand-alone version or in a laser network serving up to two machines, the installation of the laser can be modified to match the customer’s specifications. Passive cooling and the durability of the diode laser modules promise great availability and long service lives. Should one of the modules malfunction, the remaining modules will automatically raise their output, thus making sure that the process will not be interrupted. Thus there is no loss of power at the workpiece and production can continue unhindered.

Offering consistent good beam quality with high power at the workpiece, modular engineering, superb machine availability, low operating costs and simultaneous high energy efficiency, the new TruDiode 4506 is flexible and can be strongly recommended as a modern-design laser for conventional welding work and surface processing.

For more information about TRUMPF go to www.trumpf.com