June 11, 2013

Precision sensor manufacturer Micro-Epsilon has launched a lightweight thermal imaging camera that can be easily mounted to a variety of unmanned aerial vehicles (UAVs) - including micro-drones and multicopters – to carry out thermographic surveys and defect analysis of photovoltaic cells (solar panels), wind turbines, buildings and other difficult-to-access structures.

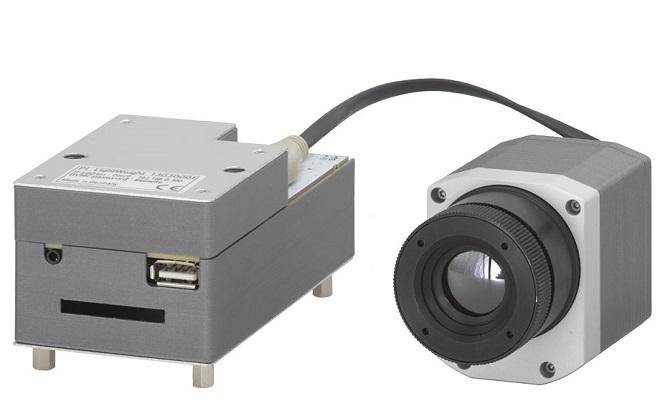

The thermoIMAGER TIM LightWeight consists of a miniature infrared (IR) camera (Micro-Epsilon’s thermoIMAGER TIM 400 or 450 thermal imager) and a miniature lightweight ‘NetBox mini’ PC. With a total weight of just 380g, this two-piece system is the ideal choice for aerial thermography applications. IR video recordings can be launched directly via a button on the camera housing; the video is stored on a microSD storage card in NetBox.

As Chris Jones, Managing Director at Micro-Epsilon UK states: “The thermoIMAGER TIM LightWeight is the lightest thermography system for aerial applications available on the market today. The combination of a miniature lightweight PC and a powerful lightweight thermal imaging camera opens up numerous potential applications in aerial maintenance and quality inspection of a variety of structures and systems, including solar energy installations, wind power systems and for thermographic surveys of buildings and other tall structures where manual inspection would be costly and time consuming.”

In a recent application, the thermoIMAGER TIM LightWeight was used to carry out defect analysis on solar panels. Any defective photovoltaic cells can destroy an entyre solar module and so thermography is an effective method of preventative maintenance. For example, any noticeable differences in temperature can be detected by the thermal imager, as well as defects relating to electrical and mechanical components, installation and processing-related defects, including short circuits, inactive cells, moisture and poorly soldered joints. As part of scheduled maintenance operations, thermography can also provide valuable information for resolving warranty claims.

Inspection using IR cameras are performed in a non-contact, non-destructive manner at a safe distance from the target. The thermoIMAGER TIM LightWeight IR camera is therefore an ideal choice for use on a multi-drone or quadrocopter (a small, remote-controlled helicopter with four blades). Design factors to consider when using an IR camera as part of aerial operations include low weight, autonomous control and sufficiently high camera resolution to ensure high quality IR images.

The compact high resolution thermoIMAGER TIM LightWeight IR camera measures just 111 x 55 x 45mm. The camera provides full radiometric IR inspection with an optical resolution of 382 x 288 pixels in 12ms per frame. Thermal sensitivity is down to 40mK, so even the slightest temperature variations can be reliably detected. A 20Hz video signal is generated during inspection flights and radio-transmitted to the UAV operator. In parallel, radiometric imagery is stored on an SDHC memory card at a frequency of 35Hz. A GigE interface is provided to download the video from the NetBox PC after the flight. The package is completed by Micro-Epsilon’s versatile PI Connect software for data recording and analysis. Connection of an HD video camera is supported via an additional USB port.

For more information on the thermoIMAGER TIM LightWeight, please visit www.micro-epsilon.co.uk