June 13, 2013

by Angela Herring

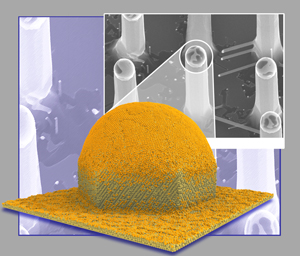

The next breakthrough in highly efficient battery technologies and solar cells may very well be nanoscopic crystals of silicon assembled like skyscrapers on wafer-scale substrates. An important route for growth of these nanoscale “whiskers”—or nanowires—involves alloyed metal droplets.

Moneesh Upmanyu, an associate professor in the Department of Mechanical and Industrial Engineering, has been using computational tools to understand the atomic-scale interactions between these droplets and the growth of nanowires.

“The droplet is able to multitask on several levels, and that is the beauty of this growth technique,” said Upmanyu. “It catalyzes and then absorbs the growing species from the surrounding vapor, gets saturated, and eventually guides the nucleation of the growing nanowire, not unlike a jet that leaves a crystalline nanowire in its wake.”

The technique was developed decades ago for growing silicon “whiskers” that used a droplet of liquefied metal to trick vaporized silicon particles into solidifying as whiskers. The synthetic route is now widely used for growing nanowires for a variety of technologically important materials.

“The droplet ultimately gives absolute control on the growth form, yet no one knew exactly how it sculpts the nanowires into specific shapes and sizes,” said Hailong Wang, a former post-doctoral student within Upmanyu’s group and the first author on a recently published paper on this research in the journal Nature Communications. The study was performed in collaboration with researchers at Lawrence Livermore National Laboratory and Colorado School of Mines.

“There was no understanding at the atomic scale, mostly assumptions,” added Upmanyu.“Unmasking them is critical as it allows us to control the growth form and, as is the case at these small scales, form invariably dictates function.

The researchers discovered that the droplet does not uniformly wrap around the nanowire. Rather, it coaxes the growing end of the nanowire to facet into unevenly beveled edges. “This collection of truncated edges serves the same purpose as the Archimedean spirals that facilitate the growth of macroscale crystals, and that is a key part of the puzzle for large-scale growth of these crystals with prescribed form,” Upmanyu said. As the droplet collects the vaporized particles in its liquid state, they begin to saturate the system and precipitate out to form the solid wire. The precipitation is much faster on the beveled edges, which ultimately lead to layer-by-layer growth of the nanowire.

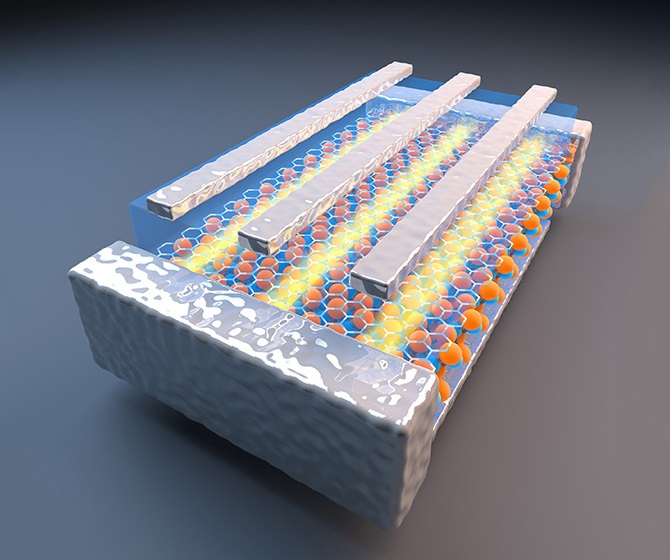

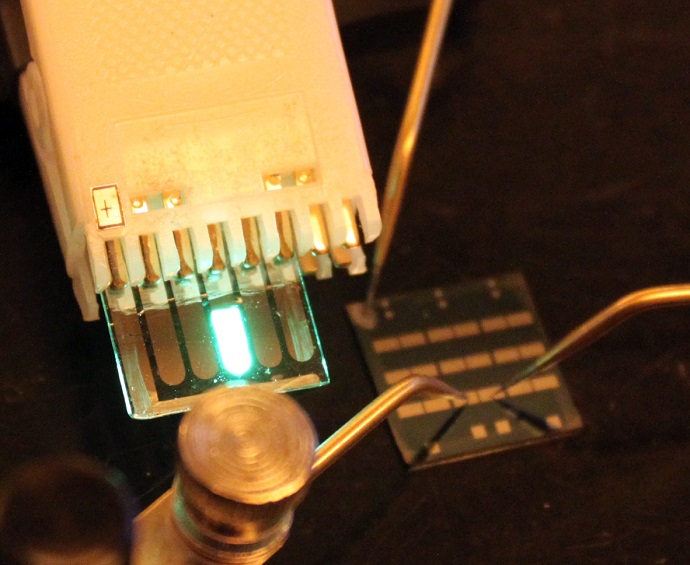

With this new understanding, researchers can begin to develop very specific crystalline structures—ranging from efficient solar panels to LED lighting—at relatively inexpensive price points. Upmanyu has already begun collaborating with other researchers at Northeastern, from physicists to biologists, to “sculpt” nanowires with particular properties.

“A fundamental understanding of nanocrystal growth remains a challenge, as the key processes require an interdisciplinary effort,” Upmanyu said. “Besides cutting-edge computational tools and algorithms, it involves elements of growth chemistry, alloy metallurgy, and surface science.”