Grenoble, France and Cambridge, UK – 10th June 2013 – ISORG and Plastic Logic have co-developed the first conformable organic image sensor on plastic, with the potential to revolutionise weight/power trade-offs and optical design parameters for any systems with a digital imaging element. First mechanical samples will be publicly unveiled at LOPE-C 2013 (ISORG / CEA booth B0-509) from 12 to 13 June in Munich, Germany.

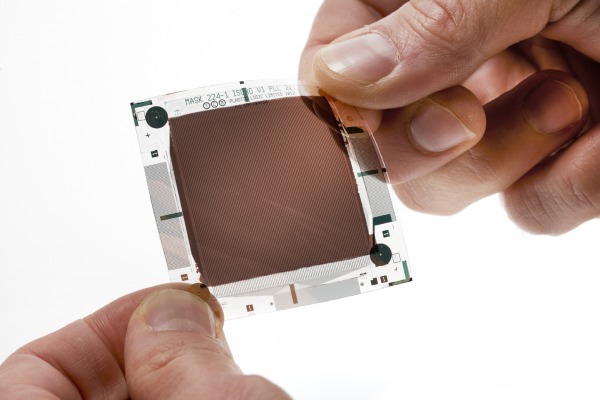

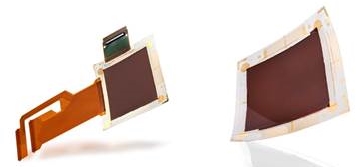

The collaboration is based on the deposition of organic printed photodetectors (OPD), pioneered by ISORG, onto a plastic organic thin-film transistor (OTFT) backplane, developed by the technology leader, Plastic Logic, to create a flexible sensor with a 4x4 cm active area, 375um pitch (175um pixel size with 200um spacing) and 94 x 95 = 8 930 pixel resolution.

The backplane design, production process and materials were optimised for the application by Plastic Logic to meet ISORG’s requirements. The result, a flexible, transmissive backplane, represents a significant breakthrough in the manufacture of new large area image sensors and demonstrates the potential use of Plastic Logic’s unique flexible transistor technology to also move beyond plastic displays. Combined with ISORG’s unique organic photodetector technology, it opens up the possibilities for a range of new applications, based around digital image sensing, including smart packaging and sensors for medical equipment and biomedical diagnostics, security and mobile commerce (user identification by fingerprint scanning), environmental, industrial, scanning surfaces and 3D interactive user interfaces for consumer electronics (printers, smartphones, tablets, etc.).

ISORG’s CEO, Jean-Yves Gomez stated: “We are extremely pleased to showcase our disruptive photodiode technology in a concrete application for imaging sensing. The ability to create conformal and large area image sensors, which are also thinner, lighter and more robust and portable than current equipment is of increasing importance, especially in the medical, industrial and security control sectors.”

Indro Mukerjee, CEO Plastic Logic said: “I am delighted that Plastic Logic can now demonstrate the far-reaching potential of the underlying technology. Our ability to create flexible, transmissive backplanes has led us not only to co-develop a flexible image sensor, but is also key to flexible OLED displays as well as unbreakable LCDs.”

About ISORG

ISORG is the leading and pioneer company in organic photodetectors and large area image sensors in printed electronics. ISORG develops a disruptive technology transforming plastic and glass into smart surfaces able to see. These new sensors are conformable, thin and lightweight with low current consumption, offering unique advantages over traditional image sensors in terms of sensing area, cost per area ratio and mechanical integration. These sensors enable creation of many innovative products such interactive surfaces for object detection and recognition, large area scanning surfaces, revolutionary user interfaces for consumer products. ISORG technology opens innovation for medical, industry and consumer markets.

ISORG has industrialized the process with its pilot manufacturing line in Grenoble and plans mass production volumes for end 2014 with its manufacturing unit in Grenoble area.

Find more on ISORG and its disruptive technology by visiting http://www.isorg.fr

About Plastic Logic

Plastic Logic is the recognised leader in organic thin-film transistors and has been at the forefront of research and investment into plastic electronics since the company was founded by researchers from the Cavendish Laboratory at Cambridge University. The company has industrialised the process and now manufactures highquality flexible plastic displays (colour and monochrome) of various sizes. These unbreakable daylight readable displays are conformal, thin and lightweight with low battery consumption, offering huge advantages over conventional screens as they are extremely flexible with proven lifetimes of over five years and more than 10 million page updates. Flexible, bendable displays enable revolutionary design possibilities and are set to transform existing markets, such as signage, wristwatches and wearable devices, automotive as well as many others. Plastic Logic is backed by major investors including Oak Investment Partners and Rusnano.

Find out more about Plastic Logic and its robust, flexible displays by visiting http://www.plasticlogic.com and http://www.youtube.com/plasticlogic