There’s a fresh wind in laser marking. TRUMPF presents two world premieres at the “Laser” trade show in Munich: the new laser TruMark 3330 and the new workstation TruMark Station 3000.

06/22/2015

Ditzingen, June 22, 2015 – TRUMPF is expanding its TruMark Series 3000 with the new TruMark 3330 ultraviolet laser. In addition to inscribing glass, ceramics and organic materials, the primary use for the diode-pumped solid-state laser is marking plastics. The new TruMark 3330 is equipped with an efficient air cooling system, significantly reducing maintenance effort and in this way lowering the laser’s operating costs. An additional benefit of the new marking laser is its low energy consumption – while getting more work out of that power. Over and above this, the new TruMark 3330, thanks to its non-proprietary interface architecture and the so-called plug-and-produce connection, is flexible in its utilization. It can be integrated into new or existing assembly lines without difficulty and can communicate with the components in the manufacturing system using standard interfaces such as ProfiBus, ProfiNet or EtherCAT. Also new to the TruMark Series 3000 are the scanner optics integrated into the marking laser. They offer higher precision and greater dynamics and, in turn, higher laser productivity and enhanced marking quality.

TruMark 3330

Its wavelength of 355 nanometers, in the infrared spectrum, makes the new TruMark 3330 superb for marking plastics.

Photo: TRUMPF

Heightened contrast, thanks to UV light

Operating at a wavelength of 355 nanometers, the TruMark 3330 opens up new possibilities for labeling plastics. That is because synthetics absorb the energy of the short-wave UV light far better than an infrared laser beam. This may eliminate the need for expensive additives. In this way UV lasers offer significantly better inscription, at greater contrast and optimal labeling quality – along with high processing speed. Thanks to the excellent beam quality of M² < 1.5, the laser beam can be focused on a very small beam spot. The laser power absorbed by the material causes a reaction in the plastic, one which is primarily photochemical. This type of machining is exceptionally gentle on the material and yields very good surface quality. At the same time, the high pulse-to-pulse stability in the TruMark 3330 offers dependable reproducibility in the work and uniform high quality of the inscriptions.

New marking workstation for medium lot sizes

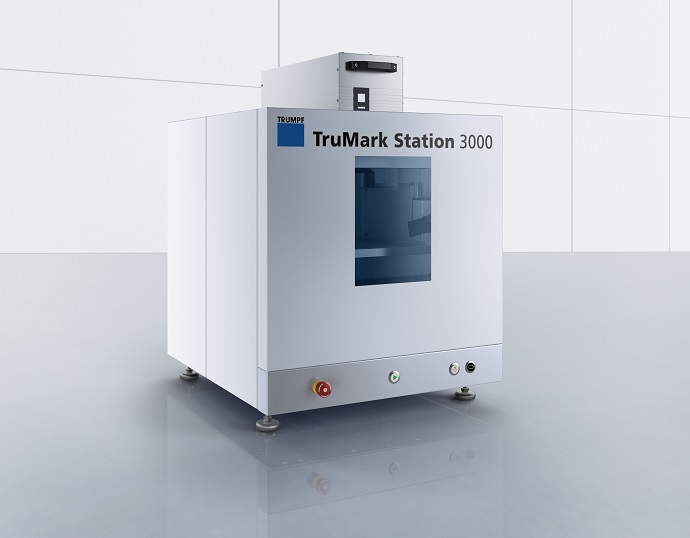

By adding the new TruMark Station 3000, TRUMPF is rounding out its line in marking workstations. The new TruMark Station 3000 extends the portfolio of workstations already available – the 1000, 5000 and 7000. It is especially advantageous for users who need to ensure traceability in small and medium-sized production runs and who wish to integrate the marking process into their own manufacturing. Here, laser safety class 1 guarantees maximum protection for the user. The new workstation has a large interior space so that it can accept components up to 350 x 450 x 200 millimeters in size and weighing a maximum of twelve kilograms. If necessary, the transfer flaps installed at the sides of the case can be removed. This lets the user integrate the workstation into an assembly line or, alternatively, to employ it for marking even larger components. A motorized Z axis, which can be software-controlled, makes for convenient positioning of the components. In addition, the focal position of the laser can be adjusted perfectly to comply with requirements. As an option, the workstation is also available with an additional axis of rotation.

Plastic marking applications

The TruMark 3330 makes it possible to apply inscriptions at various levels, without having to move the laser or the workpiece.

Photo: TRUMPF

Regardless of whether the operator is seated or standing, the new TruMark Station 3000 is available in a compact desktop version or as a convenient stand-alone version with a base. Depending on requirements, all TRUMPF marking lasers from the TruMark Series 1000, 3000 and 5000 may be used. A suction unit is also available as an option.